Device and method for ultra precise polishing of double-frequency acoustic cavitation nanofluid under magnetic control action

A nano-fluid and acoustic cavitation technology, which is applied in the field of equipment manufacturing, can solve the problems of low surface processing accuracy, poor surface quality, and uncontrollable water jetting, and achieve high efficiency, easy transformation and production, and equipment structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the drawings and embodiments.

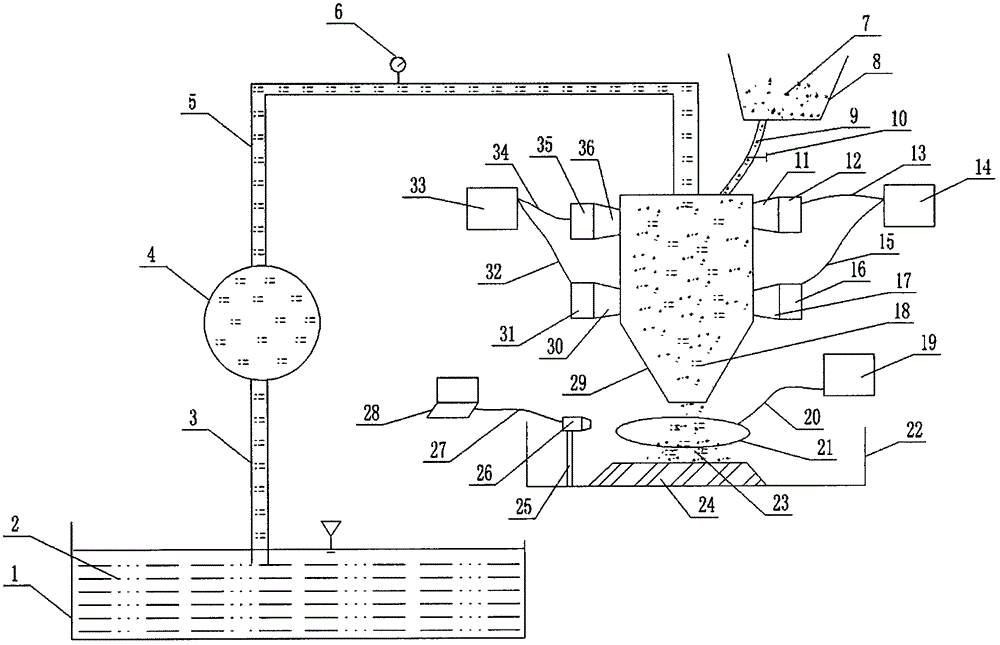

[0020] Such as figure 1 As shown, the present invention includes a polishing liquid pool 1, a hydraulic pump 4, an ultrasonic reactor 29, a dual-frequency ultrasonic device, a nano abrasive grain container 8, an AC power source 19, an AC coil 21, and a workpiece frame 22. The hydraulic pump 4 The upper end of the hydraulic pump 4 and the ultrasonic reactor 29 are connected by a second connecting pipe 5, and the polishing liquid pool 1 is provided with a polishing liquid 2 The nano-abrasive container 8 is located above the ultrasonic reactor 29 and is connected by a third connecting pipe 9, and the nano-abrasive container 8 is provided with nano-abrasive particles 7; the workpiece machine The frame 22 is arranged below the ultrasonic reactor 29, the AC coil 21 is arranged between the ultrasonic reactor 29 and the workpiece frame 22, the workpiece frame 22 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com