Hydraulic auxiliary drive system by adopting wheel hub motors

An auxiliary drive and hydraulic wheel technology, applied in the direction of servo motors, servo motor components, fluid pressure actuators, etc., can solve the problems that cannot meet the large flow requirements of wheel hub motors, cannot meet the power requirements, etc., and achieve simple layout and installation Convenience, small structure size, and the effect of improving the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

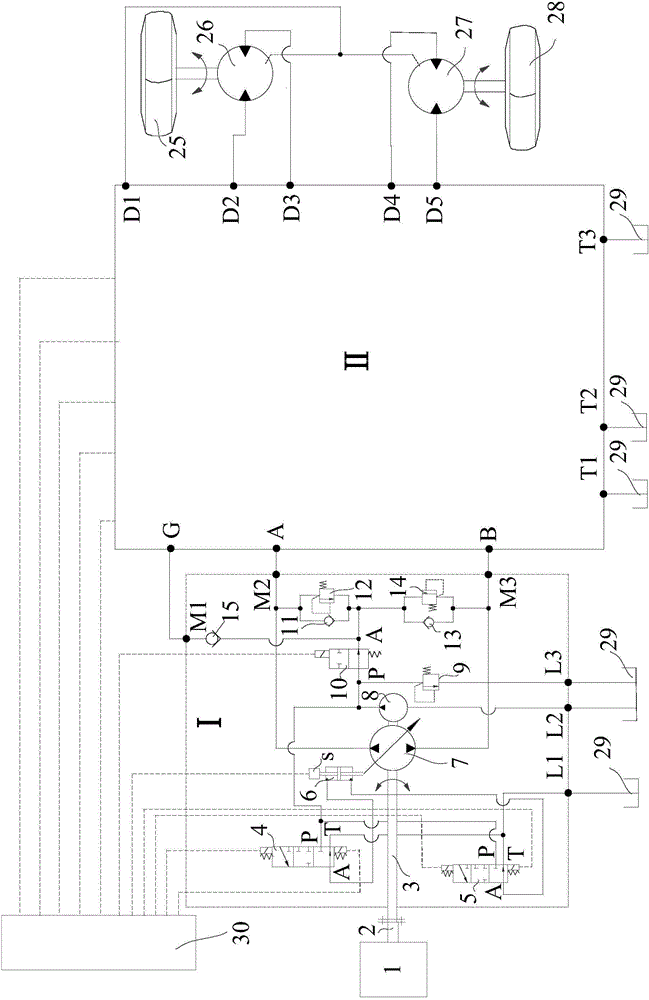

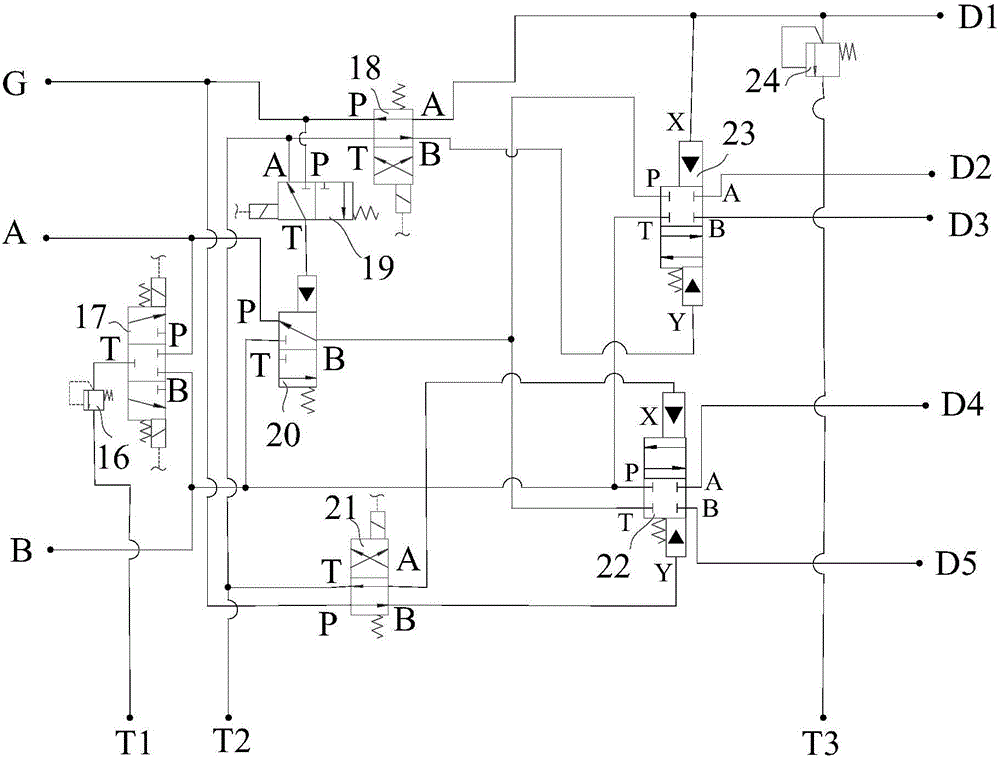

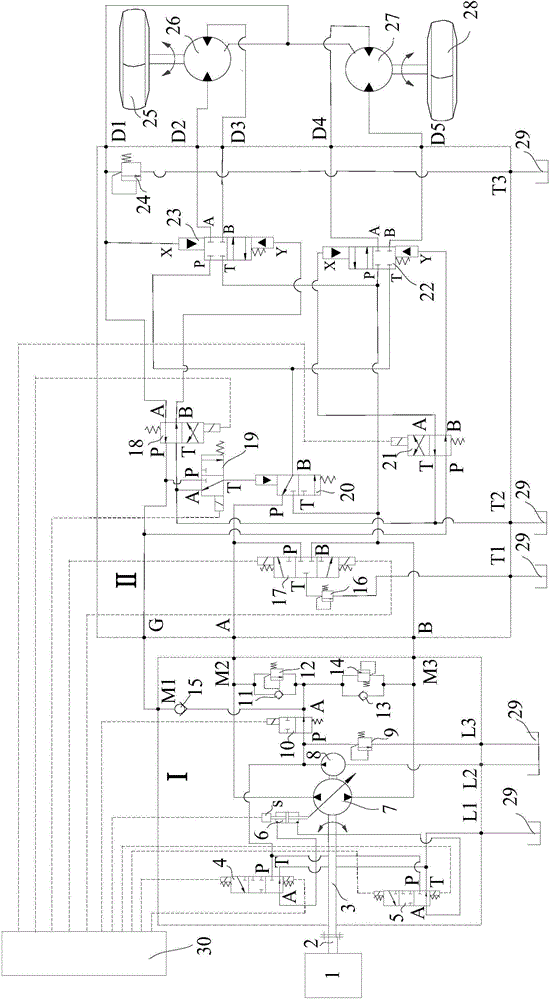

[0037] See attached figure 1 , the hydraulic hub motor auxiliary drive system proposed by the present invention includes a hydraulic pump assembly I, a control valve group II, a controller 30, a power take-off device 1, a power take-off device output shaft 2, a left front wheel 25, a left hub motor 26, a right hub Motor 27, right front wheel 28, oil tank 29.

[0038] See attached figure 1 , the power take-off device 1 and the output shaft 2 of the power take-off device provide power for the hydraulic pump assembly I, and the output shaft 2 of the power take-off device and the input shaft 3 of the hydraulic pump assembly are mechanically connected, and the connection method can be a common key or a spline pair Or connected through a universal joint, the function of the power take-off device 1 and the output shaft 2 of the power take-off device is to transmit power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com