Soil improvement conditioner as well as preparation method and application thereof

A soil improvement and conditioner technology, which is applied in the agricultural field, can solve the problems of complex component formulation and high cost of the improver, and achieve the effects of low price, low production cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

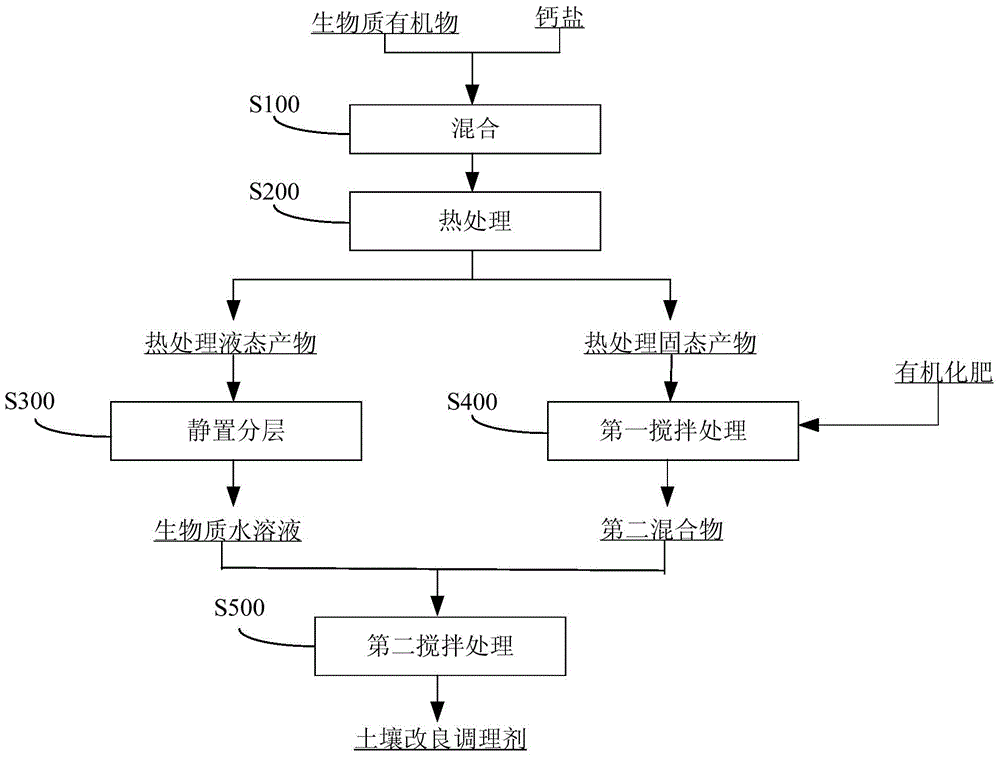

Image

Examples

Embodiment 1

[0062] Utilize the method of the present invention, prepare a kind of improved conditioning agent, concrete steps are as follows:

[0063] (1) Stir and mix 65g of desulfurized gypsum and 50g of rice stalks, put them into a fixed reaction vessel, the front of the fixed reaction vessel is connected to a nitrogen tank, and the rear is connected to a sleeve condenser;

[0064] (2) Continuously feed a small amount of nitrogen into the fixed reaction vessel, heat the fixed reaction vessel to 400° C. and keep it for 1 hour, and the gas product is passed into the sleeve condenser to condense and recover the liquid product;

[0065] (3) After the reactor is cooled to room temperature, collect the solid product, and after simple crushing and crushing, stir and mix with 10g of organic fertilizer. The mixture of organic bacterial manure is stirred evenly to obtain an improved conditioning agent, and its ingredients are: 60 g of desulfurized gypsum, 20 g of biomass coke, 10 g of biomass aq...

Embodiment 2

[0068] Utilize the method of the present invention, prepare a kind of improved conditioning agent, concrete steps are as follows:

[0069] (1) Stir and mix 60g of desulfurized gypsum and 70g of sawdust, put them into a fixed reaction vessel, the front of the fixed reaction vessel is connected to a nitrogen tank, and the rear is connected to a sleeve condenser;

[0070] (2) Continuously feed a small amount of nitrogen into the fixed reaction vessel, heat the fixed reaction vessel to 500° C. and keep it for 1 hour, and the gas product is passed into the sleeve condenser to condense and recover the liquid product;

[0071](3) After the reactor is cooled to room temperature, collect the solid product and mix it with 12g of organic fertilizer. After the liquid product is allowed to stand and separate, filter to obtain the water phase product, and spray 10g of it into the mixture of the solid product and the organic fertilizer. and stir evenly to obtain an improved conditioner, the ...

Embodiment 3

[0074] Utilize the method of the present invention, prepare a kind of improved conditioning agent, concrete steps are as follows:

[0075] (1) Stir and mix 62g of desulfurized gypsum and 55g of sawdust, put them into a fixed reaction vessel, the front of the fixed reaction vessel is connected to a nitrogen tank, and the rear is connected to a sleeve condenser;

[0076] (2) Continuously feed a small amount of nitrogen into the fixed reaction vessel, heat the fixed reaction vessel to 500° C. and keep it for 1 hour, and the gas product is passed into the sleeve condenser to condense and recover the liquid product;

[0077] (3) After the reactor is cooled to room temperature, collect the solid product and mix it with 11g of organic fertilizer. After the liquid product is allowed to stand and separate, filter to obtain the water phase product, and spray 15g into the mixture of the solid product and the organic fertilizer. and stir evenly to obtain an improved conditioner, the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com