Preparation method of fluorescent brightener water solution for detergent

A technology of fluorescent whitening agent and detergent, applied in detergent compositions, surface active detergent compositions, chemical instruments and methods, etc., can solve the problems of low solubility, complicated operation, uneven mixing of slurry, etc. To achieve the effect of stable quality and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of fluorescent whitening agent aqueous solution for detergent that the present invention proposes comprises the following steps:

[0031] 1) Add 100 parts by weight of process water at 30-50°C and 10-30 parts by weight of surfactant for detergent into the stirred tank in sequence, and start stirring;

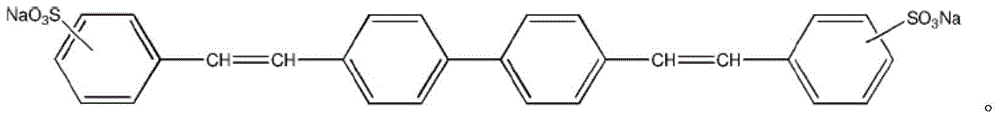

[0032] 2) After the surfactant is completely dissolved, slowly add 5 to 15 parts by weight of powdery fluorescent whitening agent into the stirring tank and continue stirring, and keep stirring for 10 to 35 minutes until the solution system is homogeneous and transparent;

[0033] 3) After observing that the whitening agent solution is clear and transparent, pump the prepared whitening agent aqueous solution into the high-level storage tank, and add it into the detergent preparation tank according to the formula ratio to produce detergent products.

[0034] During the production process, one day's brightener solution can be prepared at one tim...

Embodiment 1

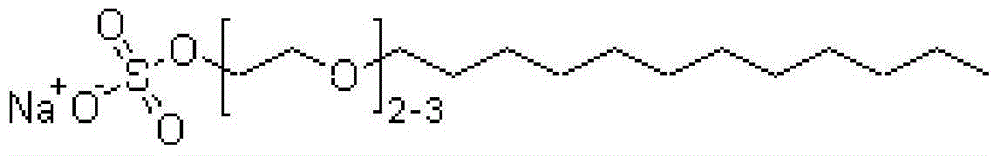

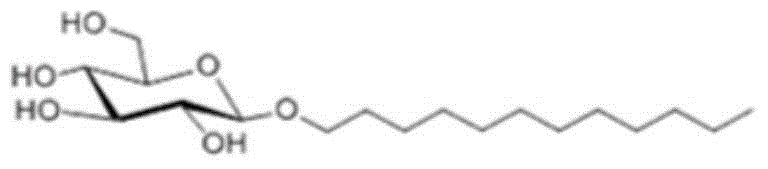

[0037] Add 1000kg of process soft water at 30°C to the stirring tank, start stirring; then add 80kg of coco alcohol polyoxyethylene ether (AEO9), 12.5kg of alkyl glucoside (APG), 20kg of sodium lauryl ether sulfate (AES), coconut Oleamidopropyl betaine 17.5kg kept stirring for 15 minutes; after the surfactant was completely dissolved, add 80kg of optical brightener (CBS), continue to stir for 25 minutes, the solution was slightly yellow, clear and transparent, stop stirring, beat Material spare.

Embodiment 2

[0039] Add 1000kg of process soft water at 35°C to the stirred tank, start stirring; then add 120kg of coco alcohol polyoxyethylene ether (AEO7) and 30kg of alkyl glycoside (APG) in sequence, and keep stirring for 12 minutes; after the surfactant is completely dissolved Add 100kg of fluorescent whitening agent (CBS) again, continue to stir for 20 minutes, the solution is light yellow and clear and transparent, stop stirring, beat the material for subsequent use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com