Melt differential electrospinning apparatus

A technology of electrospinning and melt differentiation, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of uneven fiber collection, fiber diameter refinement, etc., easy to adjust the angle, reduce fiber Diameter, easy bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

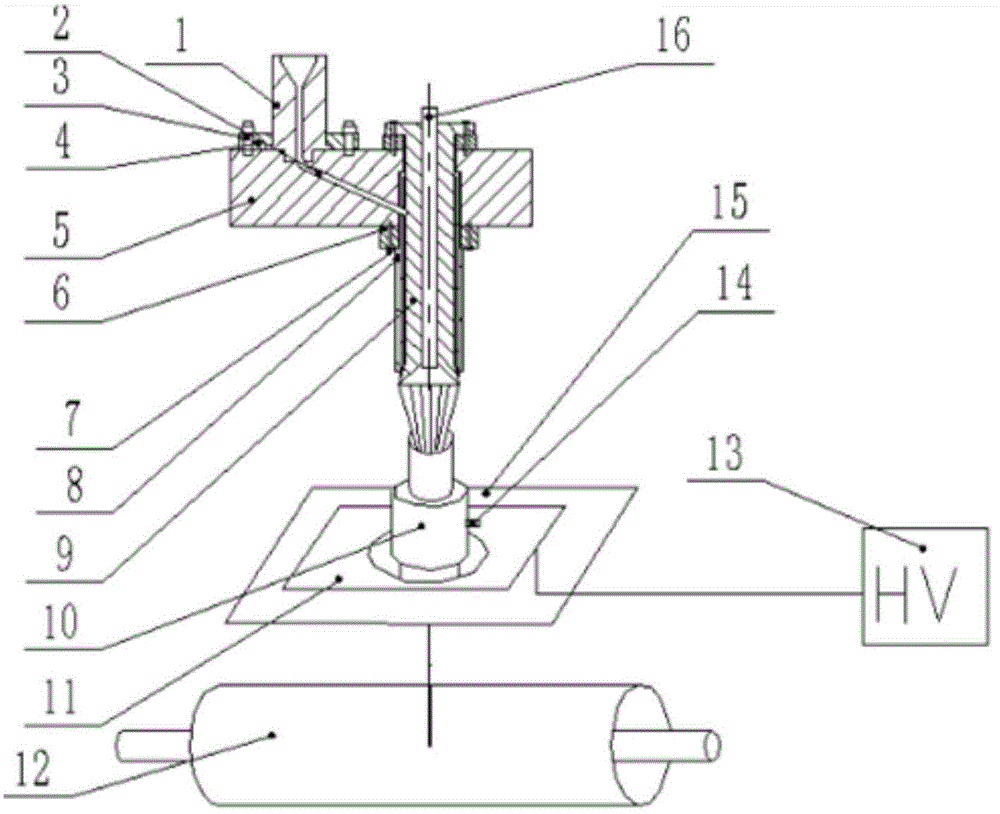

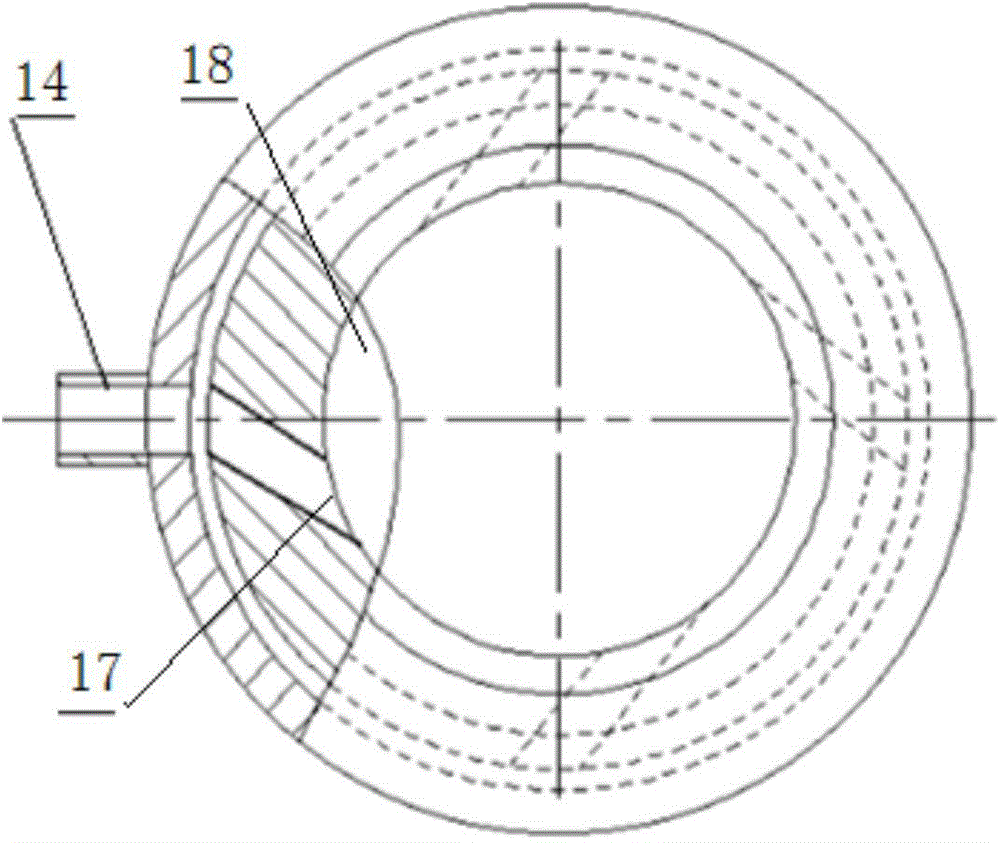

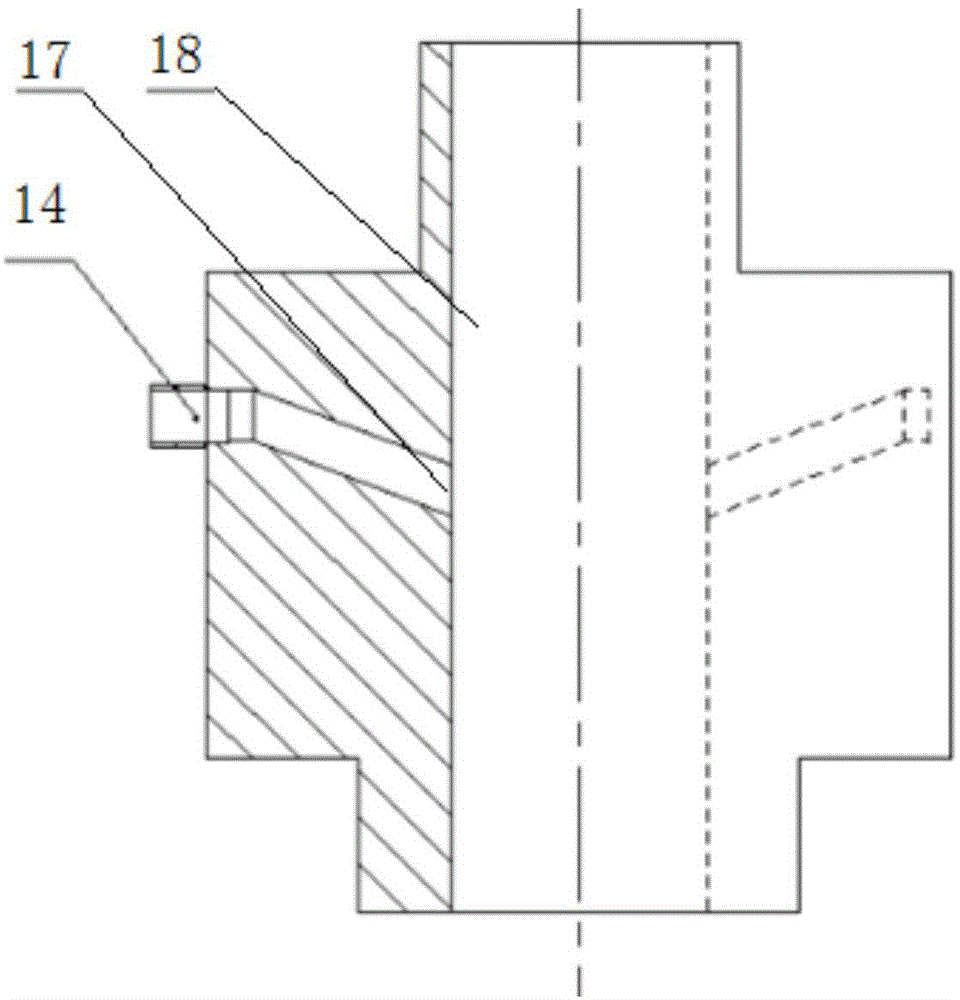

[0019] A melt differential electrospinning device of the present invention, such as figure 1 As shown, it mainly includes: barrel 1, flow channel 2 on the barrel and nozzle, barrel fixing bolt 3, barrel fixing plate 4, barrel head 5, fixing plate 6, positioning screw 7, nozzle heater 8 , nozzle barrel 9, cyclone airflow auxiliary device 10, perforated copper plate 11, fiber collection roller 12, high-voltage electrostatic generator 13, air inlet 14 of cyclone airflow auxiliary device, perforated acrylic plate 15 and outer cone airflow duct 16 . Through the positioning of the barrel fixing bolt 3 and the barrel fixing block 4, the outlet end of the barrel 1 is connected to the inlet end of the flow channel 2 of the machine head. Use the set screw 7 for axial positioning, the outer cylindrical surface of the outer conical airflow conduit 16 and the inner cylindrical hole of the machine head 5 form a gap, the melt flowing in from the barrel and the flow channel 2 on the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com