Method for detecting catalyst coking amounts in reactor by utilization of pressure drop

A detection method and pressure drop detection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that the coking amount of the catalyst cannot be detected on-line in situ, and achieve good economy, wide application range, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

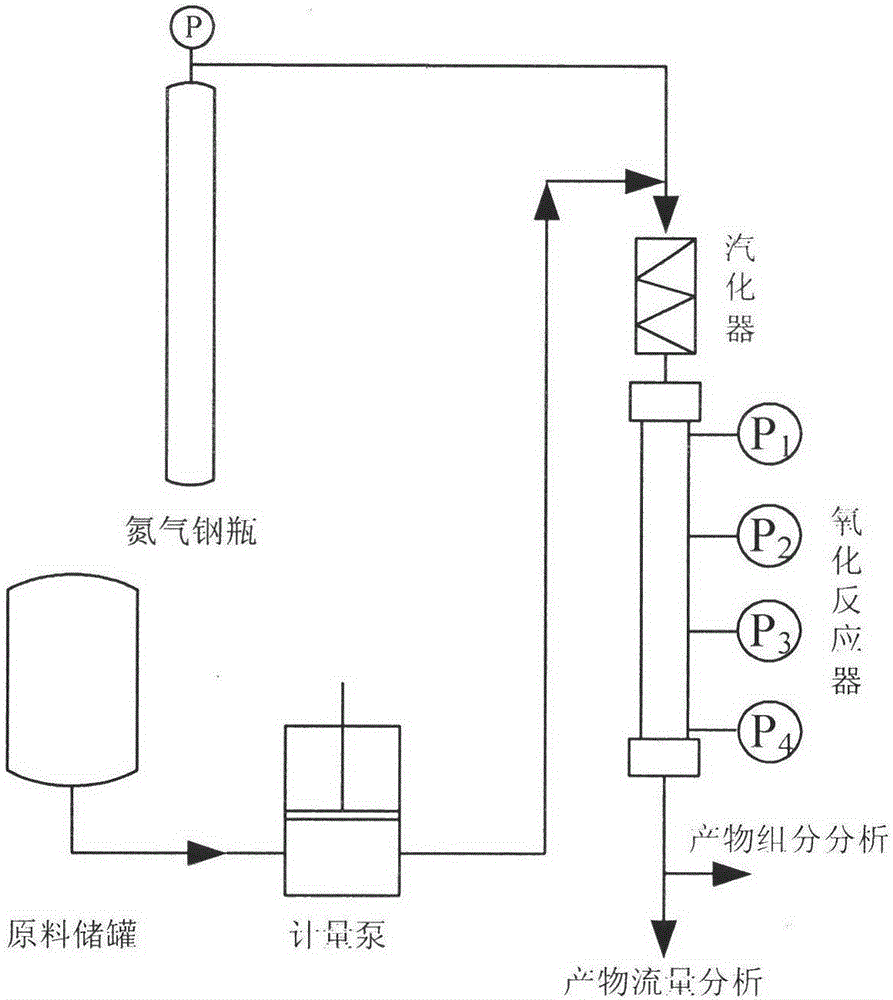

[0028] Embodiment 1: The specific implementation method is illustrated with a laboratory fixed-bed catalyst evaluation device. Such as figure 1 The device shown is a device for laboratory evaluation of the reaction performance of solid catalysts in the process of methanol to olefins. It mainly includes three parts: raw material feeding system, reaction system and product analysis system. The feeding system includes raw material tanks, metering pumps, vaporizers and nitrogen cylinders; the reaction system is mainly composed of fixed-bed reactors, and the reactors are outsourced with electric insulation devices (in figure 1 Not shown in ), to ensure that the catalytic reaction can be carried out at the preset reaction temperature; the product analysis system generally includes product composition analysis and product flow analysis.

[0029] The general fixed-bed catalyst evaluation device only has a pressure gauge installed at the inlet. In order to facilitate the detection of ...

Embodiment 2

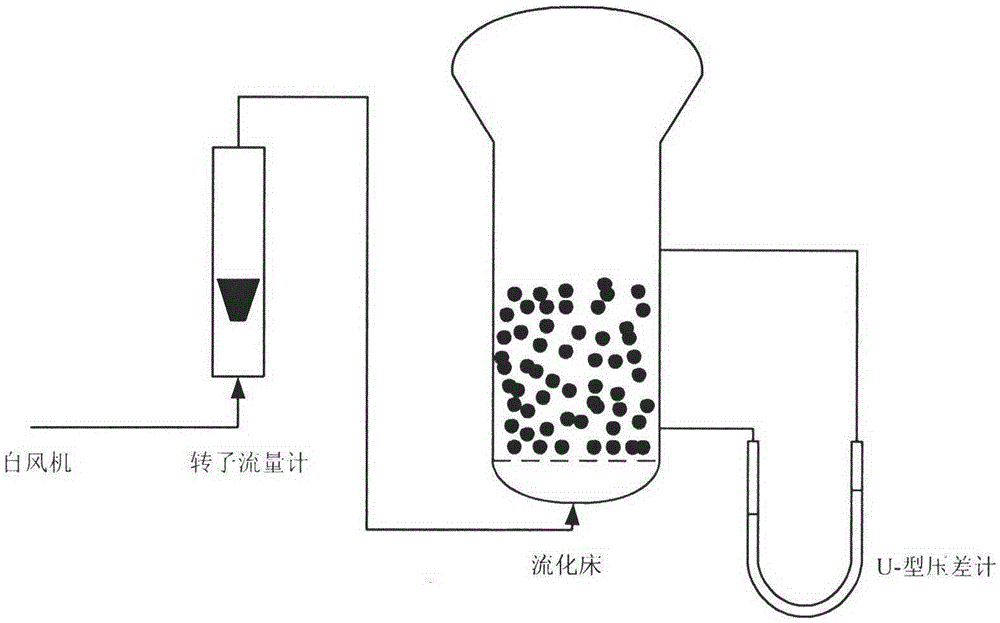

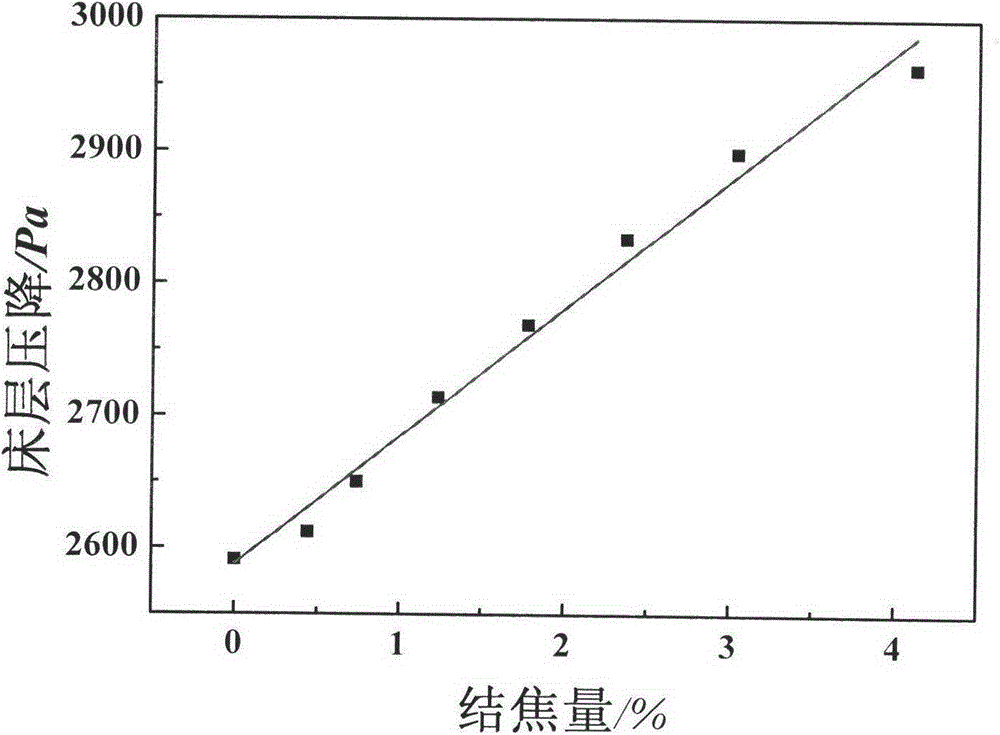

[0038] Embodiment 2: The cold model experiment device that adopts the bed pressure drop to detect the coke content of the solid catalyst in the fluidized bed reactor in the laboratory is as figure 2 shown. The fluidized bed is filled with a catalytic cracking (FCC) catalyst with a known coke content provided by a factory. The gas from the fan enters the fluidized bed after being metered by a gas flow meter. Measured out. The fluidized bed reactor used in the cold model experiment has an inner diameter of 300mm, and the height of the catalyst bed is 600mm during the experiment.

[0039] The coke content of the catalytic cracking catalyst used in the experiment process is known and the coke content is analyzed by a thermogravimetric analyzer, as shown in Table 3.

[0040] Table 3 Real coking amount of FCC catalyst

[0041]

[0042] During the experiment, the U-shaped differential pressure gauge detected the pressure drop of the entire bed, and the measured pressure drop v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com