Hypersonic efficient mixing spray pipe

A hypersonic, mixed spray technology, applied in laser parts and other directions, can solve the problems of affecting work performance, easy to block deformation, poor mixing effect, etc., to achieve the effect of easy control of parameters, not easy to block, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

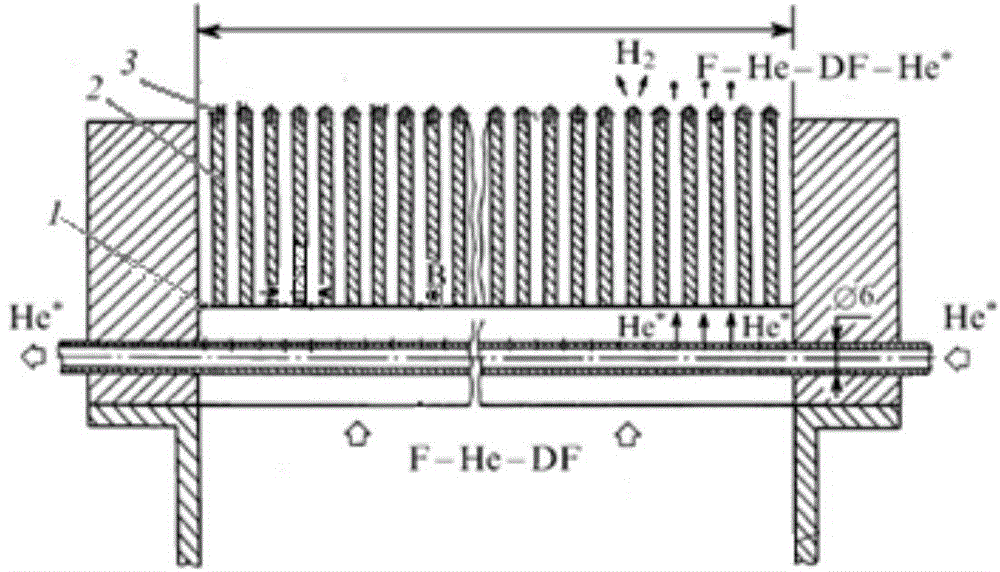

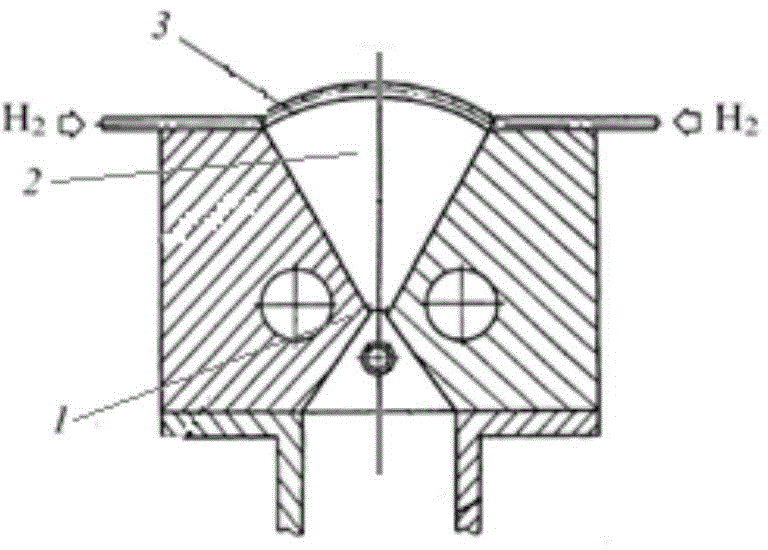

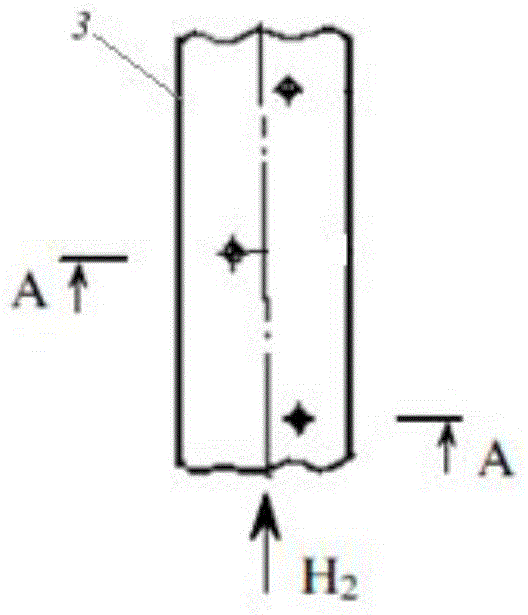

[0029] Such as Figure 1-Figure 4 As shown, the invention is a hypersonic high-efficiency mixing nozzle for a combustion-driven hydrogen fluoride laser. It consists of a hypersonic oxidizer nozzle 1, a periodic arrangement of blades 2 and a fuel nozzle 3. The main airflow F+He+DF containing fluorine atoms is accelerated by the expansion of the hypersonic oxidant nozzle 1, and at the same time, it is rectified and guided by the periodically arranged blades 2. At the outlet of the hypersonic oxidant nozzle, the secondary airflow H 2 It is ejected from the fuel nozzle array 3. The main air flow and the auxiliary air flow are mixed efficiently, accompanied by the chemical pumping reaction of fluorine atoms and hydrogen gas, to generate the vibrational excited state of hydrogen fluoride molecules, which are used as the laser light output medium, and the laser light is extracted through the optical resonant cavity. The advantages of such a mixing nozzle are: the processing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com