Visible-band multi-wavelength adjustable solid-state Raman laser

A Raman laser and visible light technology, applied in the field of lasers, can solve the problems of high cost and huge system, and achieve the effect of solving the huge system and expanding the adaptability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

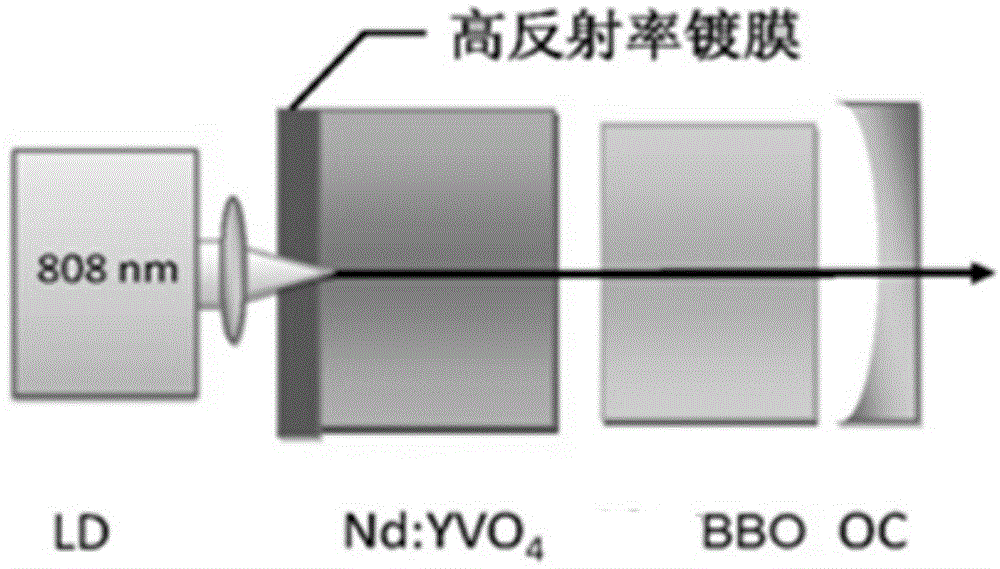

[0060] The pump source LD is an 808nm semiconductor laser diode, the maximum output power is 20W, and the output is linearly polarized light.

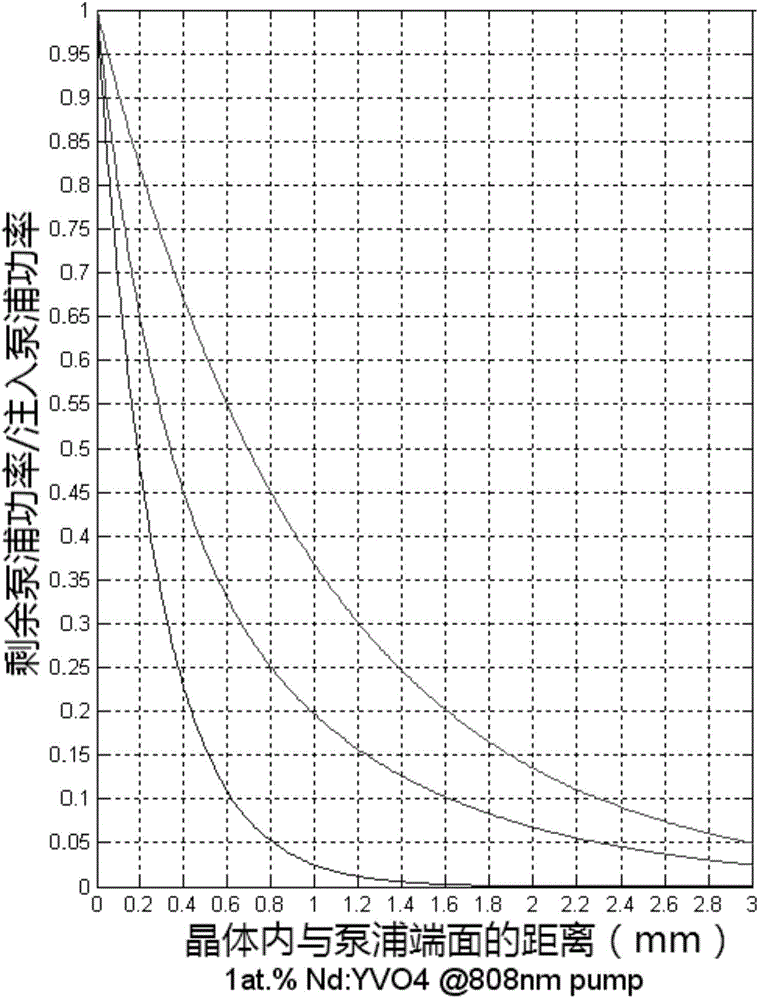

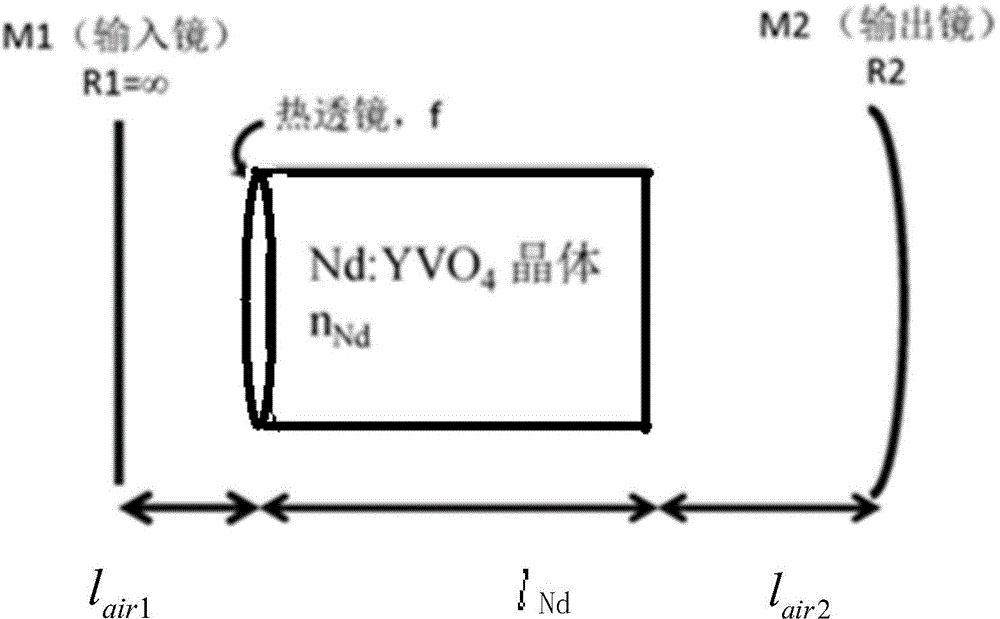

[0061] Choose 1at.% doped Nd:YVO 4 The crystal is a self-Raman crystal, the size is 4mm×4mm (cross section)×3mm (length), and the cutting method is a-axis cutting. The two light-transmitting surfaces of the crystal are coated with an 808nm anti-reflection coating, of which the side facing the pump is coated with a 1000-1500nm high-reflection coating, and the other side is coated with a 1000-1350nm anti-reflection coating to minimize intracavity losses. The polarization direction of the pump light is parallel to the c-axis of the crystal to obtain greater pump absorption. In order to alleviate the thermal lens effect in Nd:YVO4 crystal, Nd:YVO 4 The crystal is placed in a copper heat sink, and the crystal is cooled by a semiconductor refrigeration sheet or a circulating water device, and the temperature is controlled at about 25°C.

...

example 2

[0066] The above Nd:YVO 4 Crystals can also be made of Nd:GdVO 4 ,Nd:LuVO 4 Wait for self-Raman crystals to replace;

[0067]Use 2at.% doped Nd:GdVO 4 The crystal is a self-Raman crystal, the size is 4mm×4mm (cross section)×4mm (length), and the cutting method is a-axis cutting. The two light-transmitting surfaces of the crystal are coated with an 808nm anti-reflection coating, of which the side facing the pump is coated with a 1000-1500nm high-reflection coating, and the other side is coated with a 1000-1350nm anti-reflection coating to minimize intracavity losses. The polarization direction of the pump light is parallel to the c-axis of the crystal to obtain greater pump absorption. To relieve Nd:GdVO 4 thermal lensing in the crystal, but also the Nd:GdVO 4 The crystal is placed in a copper heat sink, and the crystal is cooled by a semiconductor refrigeration sheet or a circulating water device, and the temperature is controlled at about 25°C.

[0068] The BBO crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com