Liquid binder composition for binding fibrous materials

A technology of fiber materials and bonding fibers, used in fiber processing, fabrics, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0095] The following examples are provided to further illustrate exemplary adhesive compositions and methods for their preparation, but should not be construed as limiting the invention, which is described in the appended claims.

example 1

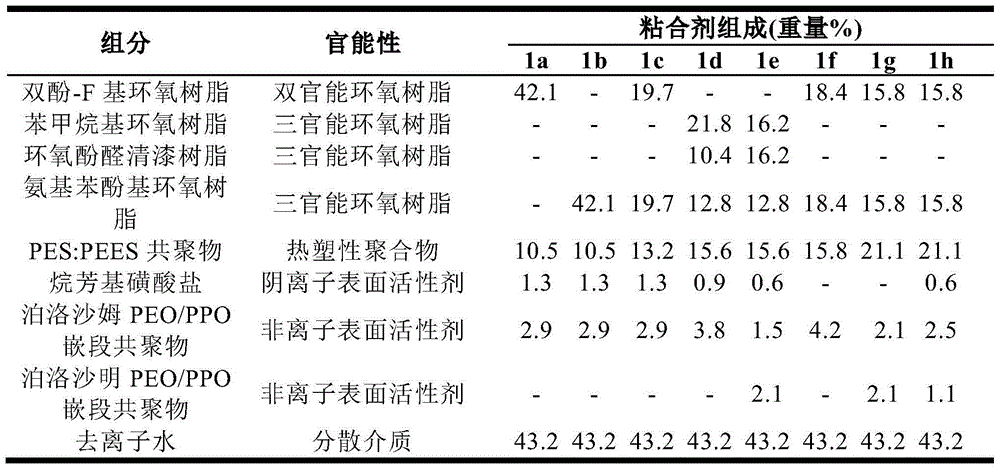

[0097] Liquid adhesive compositions were prepared based on the compositions shown in Table 1. All amounts are in weight percent (wt %).

[0098] Table 1. Liquid Adhesive Compositions

[0099]

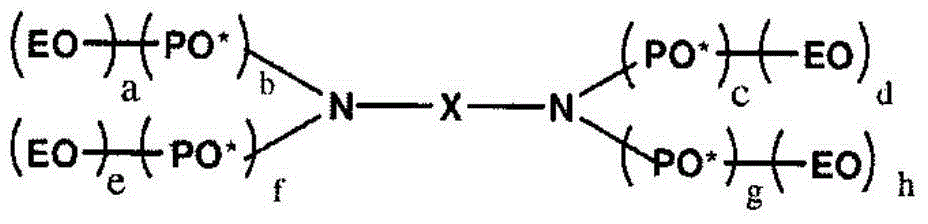

[0100] The anionic surfactants (alkaryl sulfonates) are based on chain-extending ethoxylated natural fatty diacids. The poloxamer nonionic surfactant is an AB block copolymer of polyethylene oxide (PEO) and polypropylene oxide (PPO), and the average molecular weight is in the range of 8000-18000Da. The poloxamine nonionic surfactant is an alkoxylated aliphatic diamine having an average molecular weight of about 18000-25000 Da.

[0101] In terms of non-ionic surfactants, although the polyethylene oxide block has hydrophilic properties, the polypropylene oxide block ensures strong hydrophobic properties and better affinity for the adhesive composition, thereby improving dispersion stability.

[0102] The liquid adhesive composition is prepared by dissolving the thermoplastic polyme...

example 2

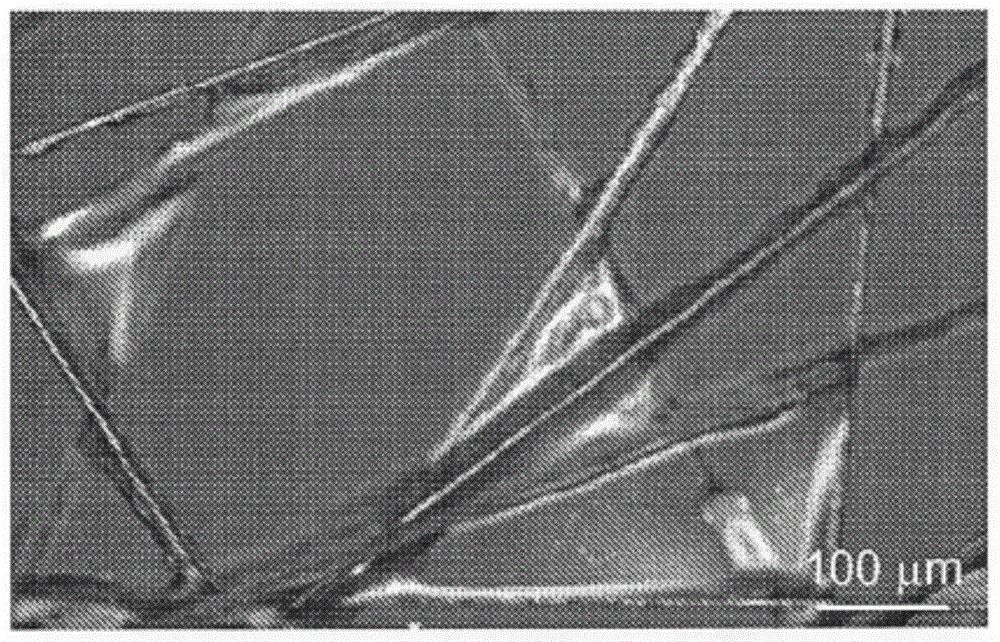

[0110] About 200 gsm of polyester seamed unidirectional non-crimp fabric (Saertex, Germany) was dip-coated with the adhesive composition described in Example 1.

[0111] For comparison purposes, the same sheet of unidirectional non-crimp fabric was also dip-coated with some commercially available adhesives. FILCO 8004 (EP1) and 345HP (EP2) are two aqueous epoxy resin emulsions with solids contents of 63% and 53% respectively (available from COIM Italy). HYDROSIZE PA845 (PA1) and U2022 (PU1) are aqueous 23% solids polyamide 4,6 and 59% solids polyurethane dispersions respectively (available from Michelman, US). NEOXIL NX962D (EP3) is an aqueous 54% solids bisphenol-A based epoxy resin emulsion (available from DSM).

[0112] All adhesive coated fabrics were dried at 100°C for 3 minutes and further dried in a 130°C oven for 4 minutes.

[0113] The adhesive-coated fabrics were evaluated for drapability, abrasion resistance, shrinkage, and self-adhesive ability.

[0114] Drapabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com