Palm-kernel meal with effect of removing antinutritional factors, preparation method and application thereof

An anti-nutritional factor, palm kernel meal technology, applied in the application, climate change adaptation, food processing and other directions, can solve the problems of poor palatability, high content of anti-nutritional factors, limited addition ratio, etc., to achieve low cost, increase protein content, The effect of improving digestion and absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

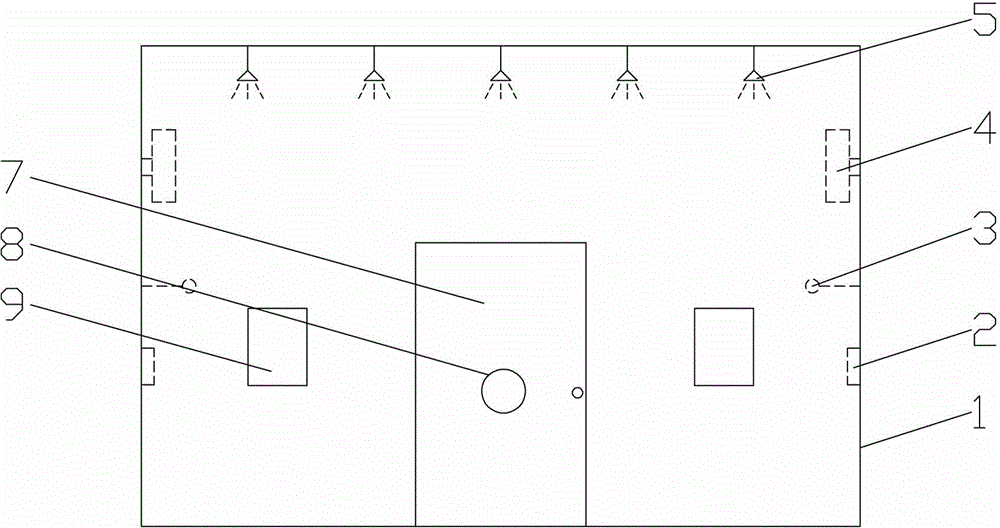

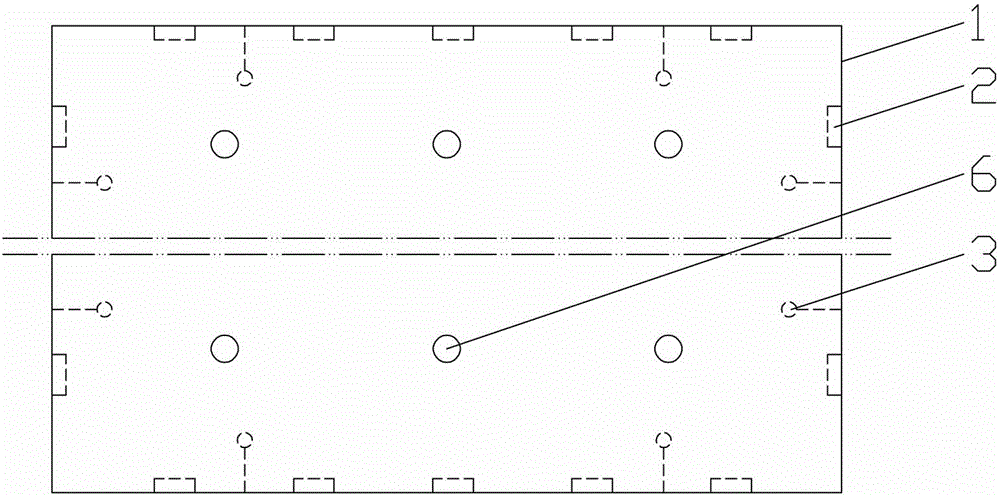

Image

Examples

Embodiment 1

[0072] A palm kernel meal without anti-nutritional factors in this embodiment is obtained by physically pulverizing the unprocessed palm kernel meal raw material, simulating digestion in the gastrointestinal tract environment of monogastric animals, aerobic fermentation, and drying at low temperature. Palm kernel meal with anti-nutritional factors removed, its product indicators are: crude protein content: 28%, crude fat content: 8%, pH value: 4.6, viable count ≥ 20×10 10 cfu / g.

[0073] The crude protein content in the palm kernel meal raw material described in this example is 14%, and the crude fat content is 9%.

[0074] The preparation method of the palm kernel meal that removes anti-nutritional factors of the present embodiment may further comprise the steps:

[0075] (1) Crushing: Use a pulverizer to crush the palm kernel meal into 0.8mm palm kernel meal powder to make the material structure fluffy;

[0076] (2) Simulate digestion in the gastrointestinal tract environm...

Embodiment 2

[0096] A palm kernel meal without anti-nutritional factors in this embodiment is obtained by physically pulverizing the unprocessed palm kernel meal raw material, simulating digestion in the gastrointestinal tract environment of monogastric animals, aerobic fermentation, and drying at low temperature. Palm kernel meal with anti-nutritional factors removed, its product indicators are: crude protein content: 23%, crude fat content: 8%, pH value: 4.8, number of viable bacteria ≥ 20×10 10 cfu / g.

[0097] The crude protein content in the palm kernel meal raw material described in this example is 12%, and the crude fat content is 9%.

[0098] The preparation method of the palm kernel meal that removes anti-nutritional factors of the present embodiment may further comprise the steps:

[0099] (1) Crushing: Use a pulverizer to crush the palm kernel meal into 1.2mm palm kernel meal powder to make the material structure fluffy;

[0100] (2) Simulate digestion in the gastrointestinal t...

Embodiment 3

[0119] A palm kernel meal without anti-nutritional factors in this embodiment is obtained by physically pulverizing the unprocessed palm kernel meal raw material, simulating digestion in the gastrointestinal tract environment of monogastric animals, aerobic fermentation, and drying at low temperature. Palm kernel meal with anti-nutritional factors removed, its product indicators are: crude protein content: 25%, crude fat content: 9%, pH value: 4.7, viable count ≥ 20×10 10 cfu / g.

[0120] The crude protein content in the palm kernel meal raw material described in this example is 13%, and the crude fat content is 9%.

[0121] The preparation method of the palm kernel meal that removes anti-nutritional factors of the present embodiment may further comprise the steps:

[0122] (1) Crushing: Use a pulverizer to crush the palm kernel meal into 0.6mm palm kernel meal powder to make the material structure fluffy;

[0123] (2) Simulate digestion in the gastrointestinal tract environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com