Adhesive for orthodontics and preparation method thereof

An adhesive and oral cavity technology, applied in dental preparations, pharmaceutical formulations, medical science, etc., can solve problems such as low bonding strength, weak tensile strength, and easy falling off of brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

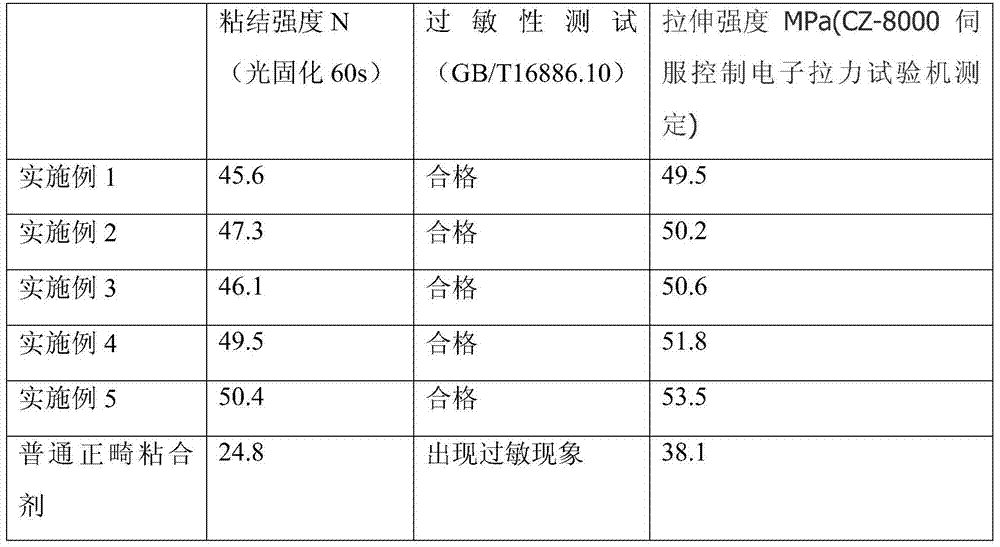

Examples

Embodiment 1

[0017] An adhesive for orthodontics, consisting of the following components in parts by mass: 19 parts of epoxy resin, 5 parts of polymethacrylate, 3 parts of n-butyl acrylate, 12 parts of carboxymethyl cellulose, ortho 5 parts of dibutyl phthalate, 32 parts of glycerin, 3 parts of silane coupling agent KH-570, 12 parts of polydibutylene, 6 parts of hydroxyapatite.

[0018] Preparation:

[0019] (1) Add epoxy resin, polymethacrylate, carboxymethyl cellulose, coupling agent, polydibutylene, and hydroxyapatite to glycerin according to the above mass parts, and stir at 110°C until completely Dissolving, stirring speed is 800r / min, obtains mixture one;

[0020] (2) Add n-butyl acrylate and dibutyl phthalate to the mixture 1 obtained in step (1), and sonicate at 75° C. for 10 minutes to obtain mixture 2;

[0021] (3) Put the mixed material 2 obtained in step (2) in a vacuum oven for vacuuming to remove solvent, the vacuum degree is 0.1MPa, the temperature is 80°C, and the time is...

Embodiment 2

[0023] An adhesive for orthodontics, consisting of the following components by mass: 37 parts of epoxy resin, 16 parts of polymethacrylate, 8 parts of n-butyl acrylate, 19 parts of carboxymethyl cellulose, 15 parts of dibutyl phthalate, 43 parts of glycerin, 10 parts of silane coupling agent KH-560, 25 parts of polydibutylene, and 21 parts of hydroxyapatite.

[0024] Preparation:

[0025] (1) Add epoxy resin, polymethacrylate, carboxymethyl cellulose, coupling agent, polydibutylene, and hydroxyapatite to glycerin according to the above mass parts, and stir at 130°C until completely Dissolving, stirring rate is 1100r / min, obtains mixture one;

[0026] (2) Add n-butyl acrylate and dibutyl phthalate to the mixture 1 obtained in step (1), and sonicate at 90° C. for 15 minutes to obtain mixture 2;

[0027] (3) Put the mixed material 2 obtained in step (2) in a vacuum oven for vacuuming to remove the solvent. The vacuum degree is 0.8MPa, the temperature is 110°C, and the time is 1...

Embodiment 3

[0029] An adhesive for orthodontics, consisting of the following components by mass: 22 parts of epoxy resin, 9 parts of polymethacrylate, 5 parts of n-butyl acrylate, 14 parts of carboxymethyl cellulose, ortho 6 parts of dibutyl phthalate, 37 parts of glycerin, 4 parts of titanate coupling agent NDZ-401, 14 parts of polydibutylene, and 11 parts of hydroxyapatite.

[0030] Preparation:

[0031] (1) Add epoxy resin, polymethacrylate, carboxymethyl cellulose, coupling agent, polydibutylene, and hydroxyapatite to glycerin according to the above mass parts, and stir at 120°C until completely Dissolving, stirring rate is 900r / min, obtains mixture one;

[0032] (2) Add n-butyl acrylate and dibutyl phthalate to the mixture 1 obtained in step (1), and sonicate at 80° C. for 12 minutes to obtain mixture 2;

[0033] (3) Put the mixed material 2 obtained in step (2) in a vacuum oven for vacuuming to remove solvent, the vacuum degree is 0.3MPa, the temperature is 90°C, and the time is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com