Vacuum impregnation coating machine

A vacuum impregnation and coating machine technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of single coating method and low efficiency, and achieve the effect of simple structure, high efficiency and easy operation of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the most preferred embodiments of the present invention.

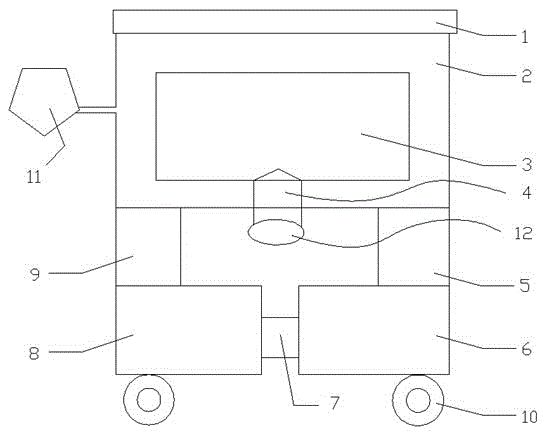

[0021] Please refer to figure 1 , a vacuum impregnation coating machine, comprising: a sealing cover 1, a vacuum impregnation box 2, a fixed table 3 for parts to be coated, an engine bearing 4, a paint outlet 5, a paint recovery bin 6, a paint one-way recovery filter 7, and a paint storage Bin 8 , paint inlet 9 , casters 10 , vacuum pump 11 and motor 12 .

[0022] Wherein, the sealing cover 1 is used for sealing the vacuum impregnation box 2 .

[0023] Wherein, the vacuum impregnation box 2 is a place for vacuum dip coating of components to be coated.

[0024] Among them, the fixed table 3 of the parts to be coated is used to fix the components to be coated, the fixed table 3 of the parts to be coated is connected to the end of the engine bearing 4, and can rotate together with the engine bearing 4, and the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com