A double-stage deep bed upflow composite filter material biological filter

A biofilter and composite filter material technology, which is applied in the direction of water pollutants, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of decreased degradation ability, inability to degrade and remove organic matter and ammonia nitrogen pollutants in water , Unable to cope with the sudden increase of pollutant concentration and other problems, to achieve the effect of promoting biological growth, improving the ability to resist the impact load of pollutants, and efficiently removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

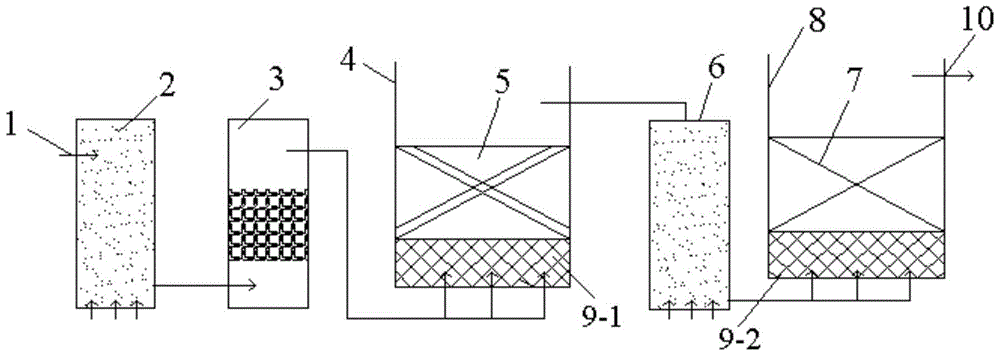

[0034] Specific Embodiment 1: This embodiment is a two-stage deep-bed upward-flowing composite filter biofilter including an ozone contact oxidation unit 2, an ozone catalytic oxidation unit 3, a first-stage upward-flowing biological filter 4, and a second-stage Upward flow biological filter 8, oxygenation unit 6, composite filter material layer 5, main filter material layer 7, first supporting layer 9-1 and second supporting layer 9-2;

[0035] The upper end of the ozone contact oxidation unit 2 is provided with a water inlet 1, the lower end of the ozone contact oxidation unit 2 is connected to the lower end of the ozone catalytic oxidation unit 3, and the upper end of the ozone catalytic oxidation unit 3 is connected to the first-stage upward flow biofilter The bottom of 4 is connected, the upper end of the first-stage upward flow biological filter 4 is connected with the top of the oxygenation unit 6, and the lower end of the oxygenation unit 6 is connected with the bottom ...

specific Embodiment approach 2

[0046] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the filler in the described composite filter material layer 5 is a mixture of zeolite and activated carbon; the particle size of the filler in the described composite filter material layer 5 0.5mm-4.0mm; the thickness of the composite filter material layer 5 is 0.1m-4m; the expansion rate of the composite filter material layer 5 is less than 5%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of zeolite in the composite filter material layer 5 is 1%-99%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com