A preparation method of all bio-based composite materials capable of rapid stereocombination after melting

A composite material and stereocomposite technology, which is applied in the field of preparation of all-bio-based composite materials, can solve the problems of unfavorable food packaging application, complex polylactic acid stereocomplex process, low rate of stereocomplex, etc., and achieves easy realization. , Improve physical and mechanical properties, the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

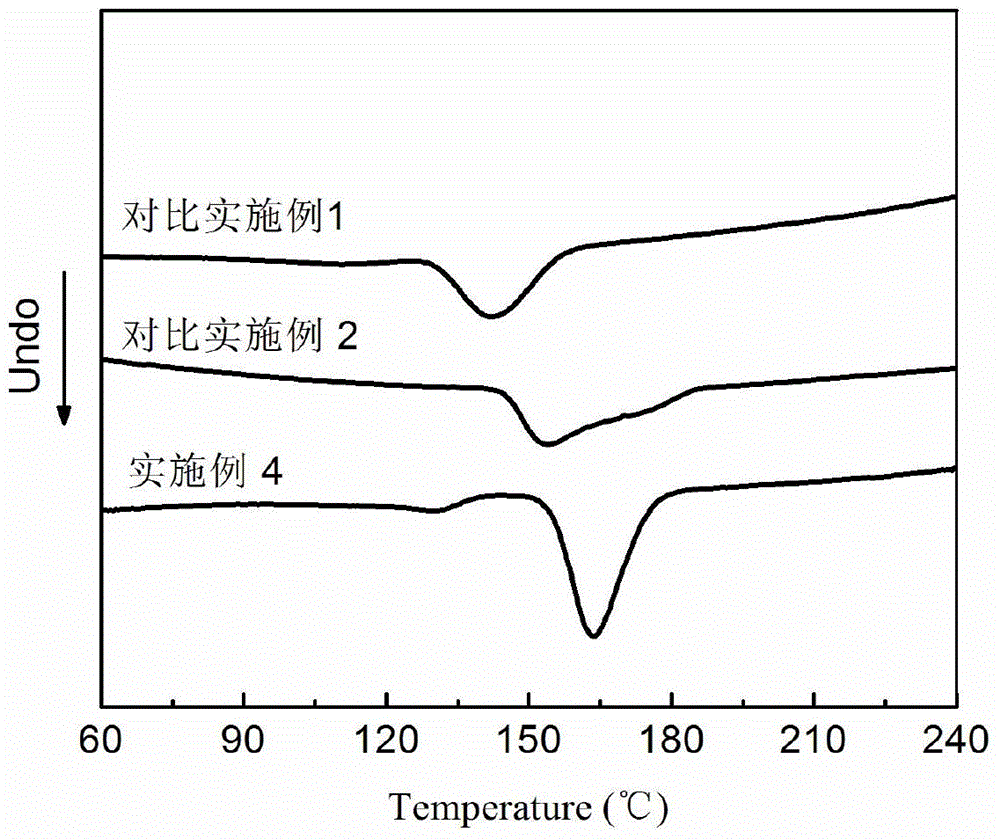

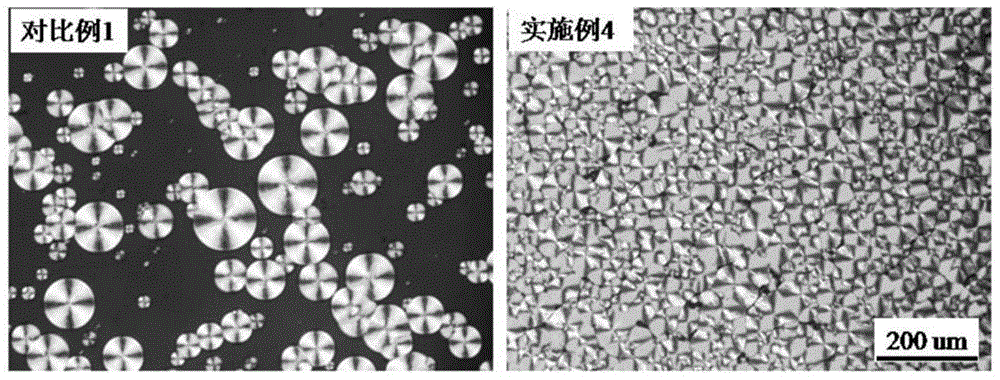

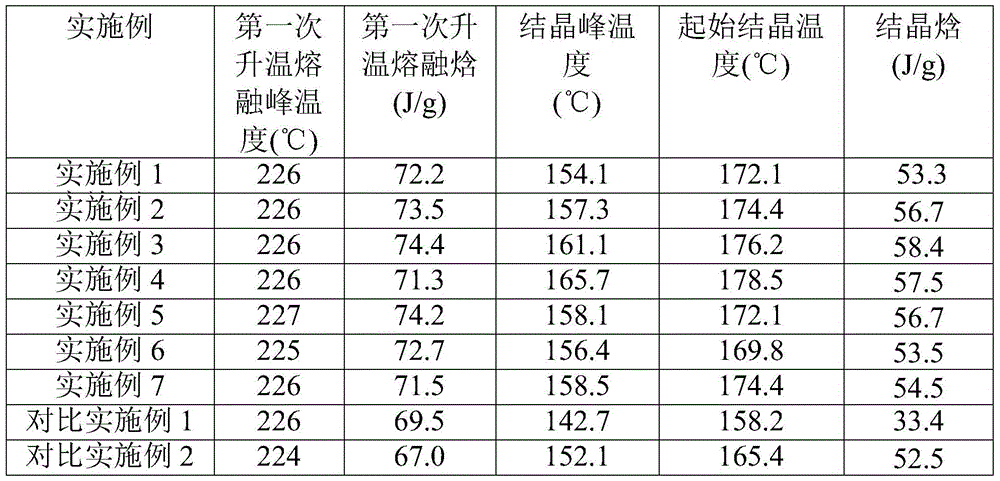

Examples

Embodiment 1

[0027] First, the L-polylactic acid and the D-polylactic acid are dissolved in chloroform at room temperature according to the weight ratio to obtain a polylactic acid mixture A, and a certain mass of nanocellulose is ultrasonically dispersed in chloroform at room temperature to obtain a mixture B. Then mixture A and mixture B were mixed and stirred thoroughly to obtain mixture C, and mixture C was desolvated at 40° C. to obtain a kind of all-bio-based composite film (wherein PDLA / PLLA / NCC=55 / 45 / 0.5, weight ratio ).

Embodiment 2

[0029] First, the L-polylactic acid and the D-polylactic acid are dissolved in chloroform at room temperature according to the weight ratio to obtain a polylactic acid mixture A, and a certain mass of nanocellulose is ultrasonically dispersed in dichloromethane at room temperature to obtain a mixture B. Then mixture A and mixture B were mixed and stirred well to obtain mixture C, and mixture C was desolvated at 40° C. to obtain a kind of all-bio-based composite film (wherein PDLA / PLLA / NCC=50 / 50 / 1, weight ratio ).

Embodiment 3

[0031] First, the L-polylactic acid and the D-polylactic acid are dissolved in the organic solvent chloroform according to the weight ratio at room temperature to obtain a polylactic acid mixture A, and a certain mass of nanocellulose is ultrasonically dispersed in chloroform at room temperature to obtain a mixture B, then mixture A and mixture B were mixed and fully stirred to obtain mixture C, and mixture C was desolvated at 40° C. to obtain a kind of all-bio-based composite film (wherein PDLA / PLLA / NCC=50 / 50 / 2, weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com