Mine air flow quality monitoring and alarm system and method based on controllable circulating air

A quality monitoring and alarm system technology, which is applied in mine/tunnel ventilation, mining equipment, mining equipment, etc., can solve problems such as increased frictional resistance, energy consumption, and increased proportion of ventilation in mining costs, so as to reduce ventilation costs and realize Energy saving, avoiding the effect of long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

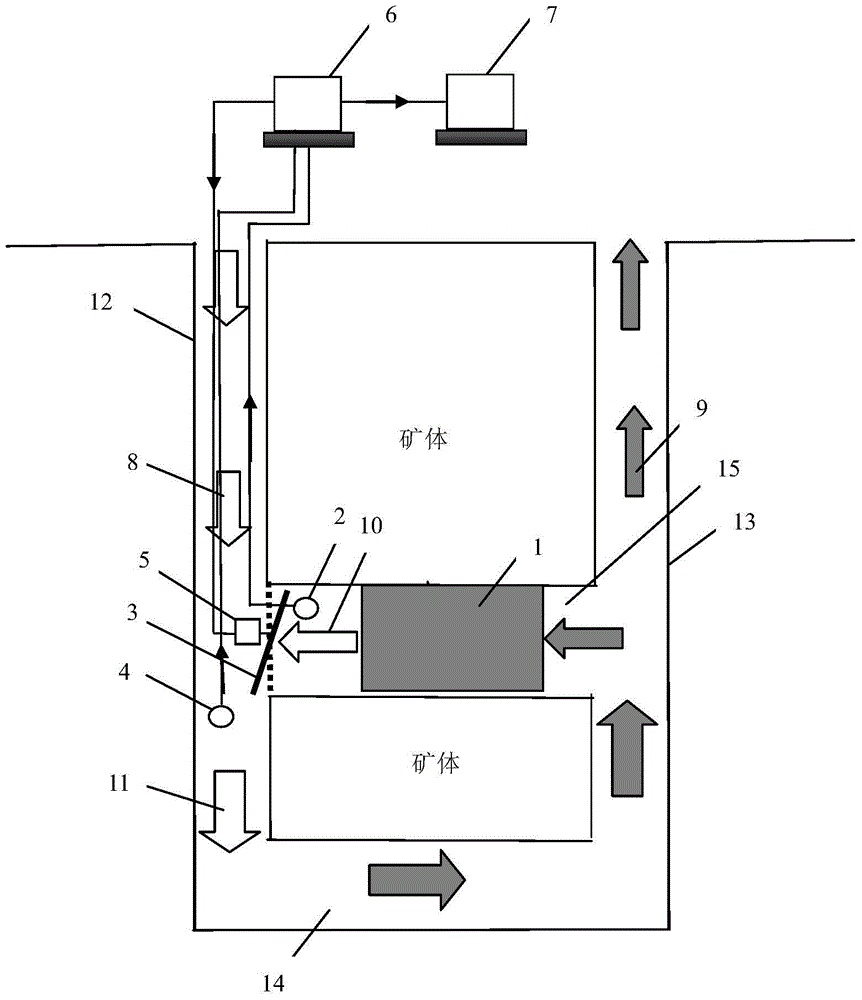

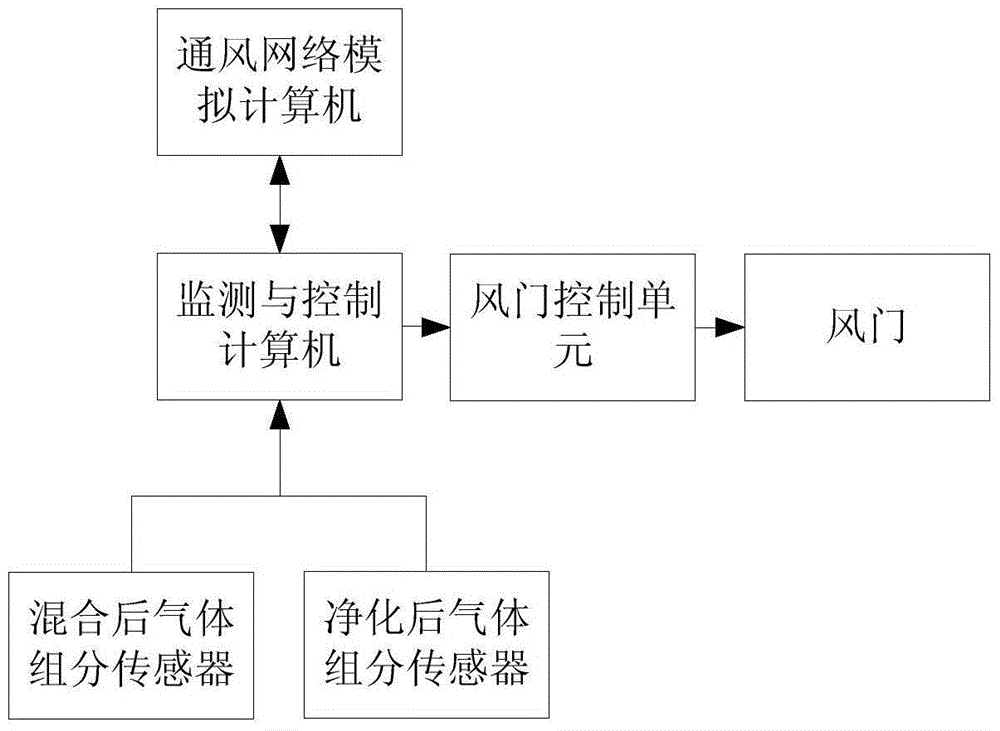

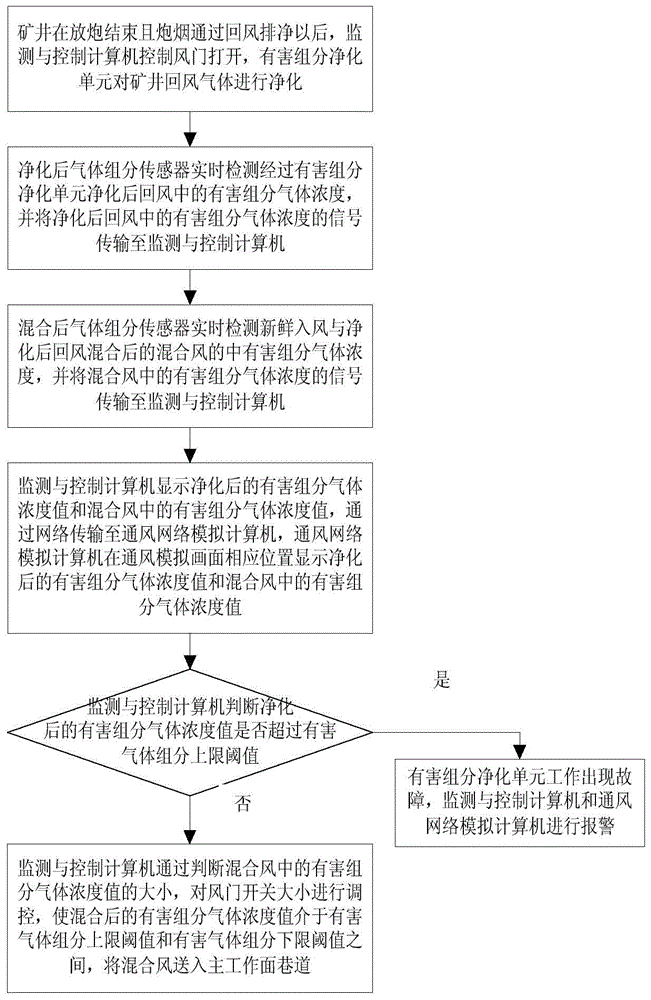

Embodiment 1

[0055] For the underground copper mining mine with a depth of 1000 meters, a 500-meter-long return air purification roadway is set in the middle section of the depth -787. The main harmful component of the copper mining mine is sulfur dioxide. Therefore, the harmful component purification unit is in the return air A row of tap water nozzles is installed every 50 meters in the purification roadway. The nozzle model is GG1 / 4A-SS10, the distance is 40cm, and tap water with a pressure of 0.5MPa is sprayed from the nozzles to form a solid cone of water mist. Wind 9 airflow contacts, the sulfur dioxide in the return airflow is absorbed by the water mist moving downward, the flow rate of each nozzle is 8 liters / min, and the airflow velocity is 2-4m / s.

[0056] The upper limit threshold of harmful gas components is set as follows: the sulfur dioxide concentration threshold is 15 mg / m3. The purified return air is mixed with the fresh incoming air through the damper, and the fresh incom...

Embodiment 2

[0062] For the underground iron ore and sulfide mining mines with a depth of 800 meters, a return air purification roadway with a length of 450 meters is set in the middle section of the depth -758. The main harmful components of the iron ore mining mines are trace amounts of sulfur dioxide and sulfur trioxide. The sub-purification unit is to install 10-20 levels of activated carbon adsorption layers with a thickness of 30-50cm in the return air purification roadway. The distance between each level of adsorption layers is 30m. The particle size of activated carbon is 1-5mm and the porosity is 0.5%. The activated carbon layer is used to absorb trace amounts of sulfur dioxide and sulfur trioxide in the return air flow, and the flow velocity of the return air flow is 0.5-2m / s.

[0063] The upper limit threshold of harmful gas components is set as follows: the concentration of sulfur dioxide is 15 mg / m3, and the concentration of sulfur trioxide is 3 mg / m3. After purification, the r...

Embodiment 3

[0069] For the underground lead-zinc mining mine with a depth of 500 meters, a return air purification roadway with a length of 320m is set in the middle section of -325. The main harmful components of the lead-zinc mining mine are a small amount of carbon monoxide and nitrogen dioxide, and the harmful components are purified The unit is to install a row of BB1 / 8-SS5 solid cone nozzles every 30 meters in the purification roadway, and the distance between the nozzles is 30cm. Add cupro ammonia to the water to form a 2%-5% cupro ammonia solution to absorb carbon monoxide in the airflow. The water can absorb the nitrogen dioxide formed in the exhaust of diesel engines in the roadway or sporadic blasting. The spray pressure is 0.5MPa, each nozzle The flow rate is 4.7 liters per minute, and the return airflow velocity is 1-4m / s.

[0070]The upper limit threshold of harmful gas components is set as follows: the concentration of carbon monoxide is 30 mg / m3, and the concentration of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com