A Thermal Dilution Sampling System for Exhaust Particles of In-Cylinder Direct Injection Gasoline Engine

An in-cylinder direct injection and sampling system technology, applied in sampling devices, preparation of test samples, etc., can solve problems such as poor dilution ratio control accuracy and inability to control dilution temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

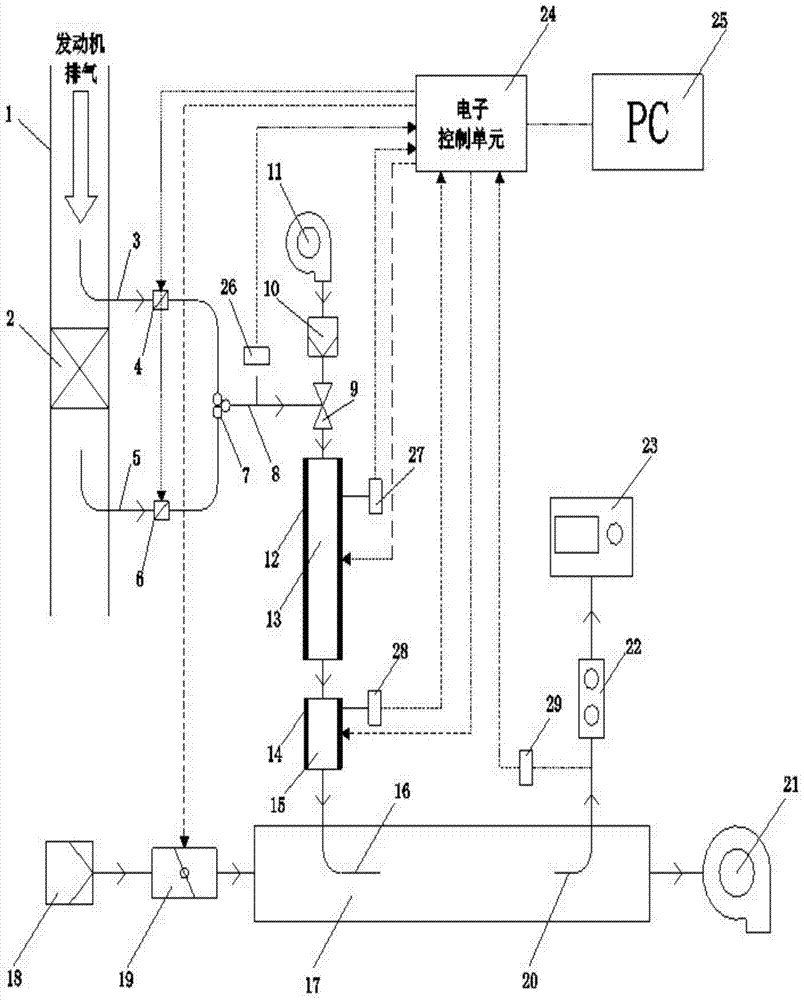

[0032] The embodiment of the present invention will be described in detail by taking the overall dilution ratio of 200:1, the dilution temperature of the primary thermodilution system at 200°C, the evaporation temperature of the volatile particle removal system at 300°C, and the sampling before the turbine as examples.

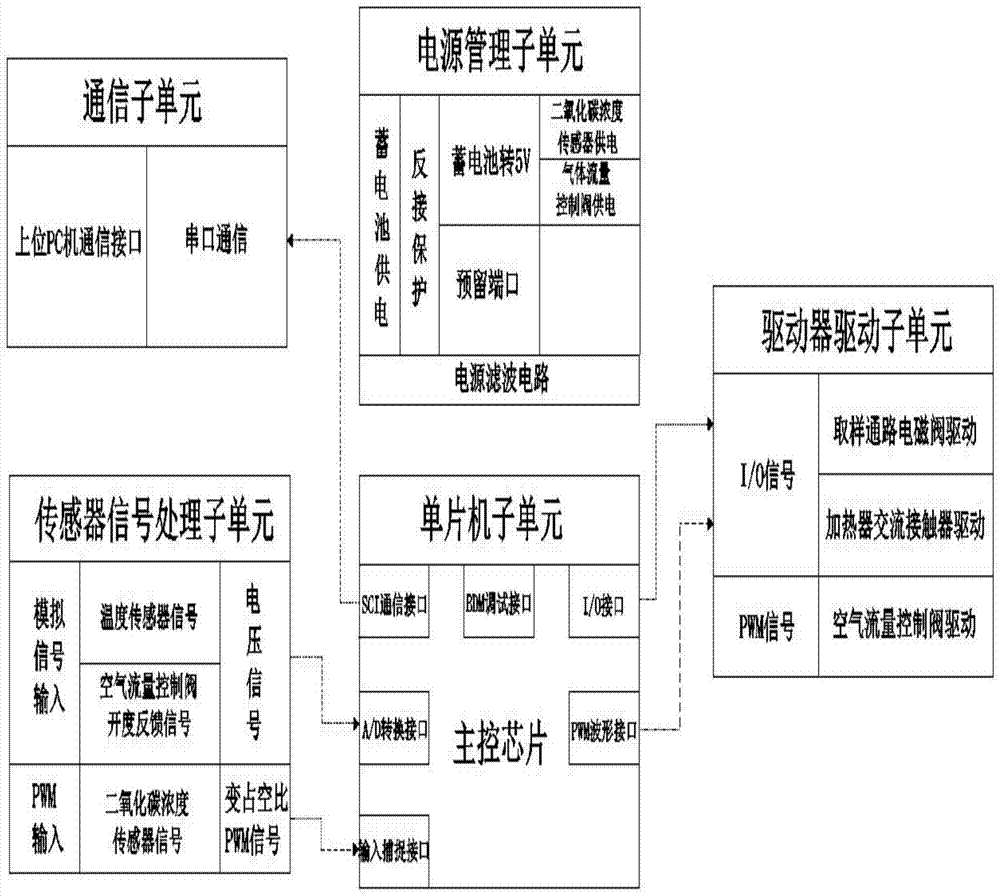

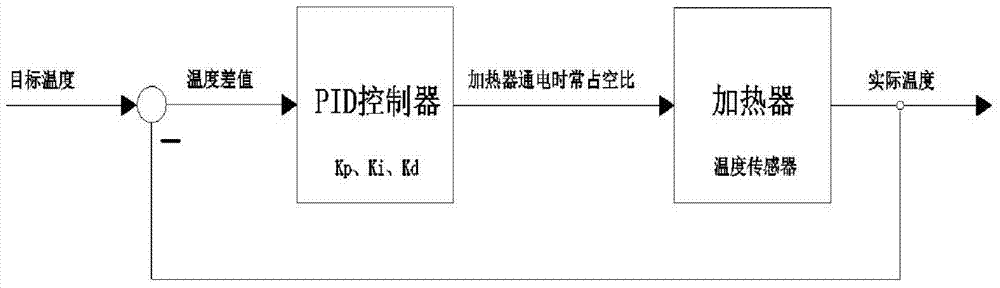

[0033] The electronic control unit of the present invention adopts the 9S12XDP512 model single-chip microcomputer as the core chip. When working, the system is powered on first, and the single-chip microcomputer then performs internal module initialization, including PWM initialization, ATD initialization, I / 0 initialization, PIT initialization, SCI initialization, and phase lock. Ring initialization, etc., and then enter the main loop function. The main loop function includes AD conversion function, temperature PID controller function, opening PID controller function, and opening control function. In addition, every time the microcontroller receives an SCI rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com