High fluidity fluororesin slurry and preparation method thereof

A technology of fluororesin and high fluidity, applied in the field of polymer chemistry, can solve the problems of less modification of processing performance, decline of mechanical and electrical properties, etc., to improve stability and flow performance, volatile removal, lower threshold and Effect of molding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

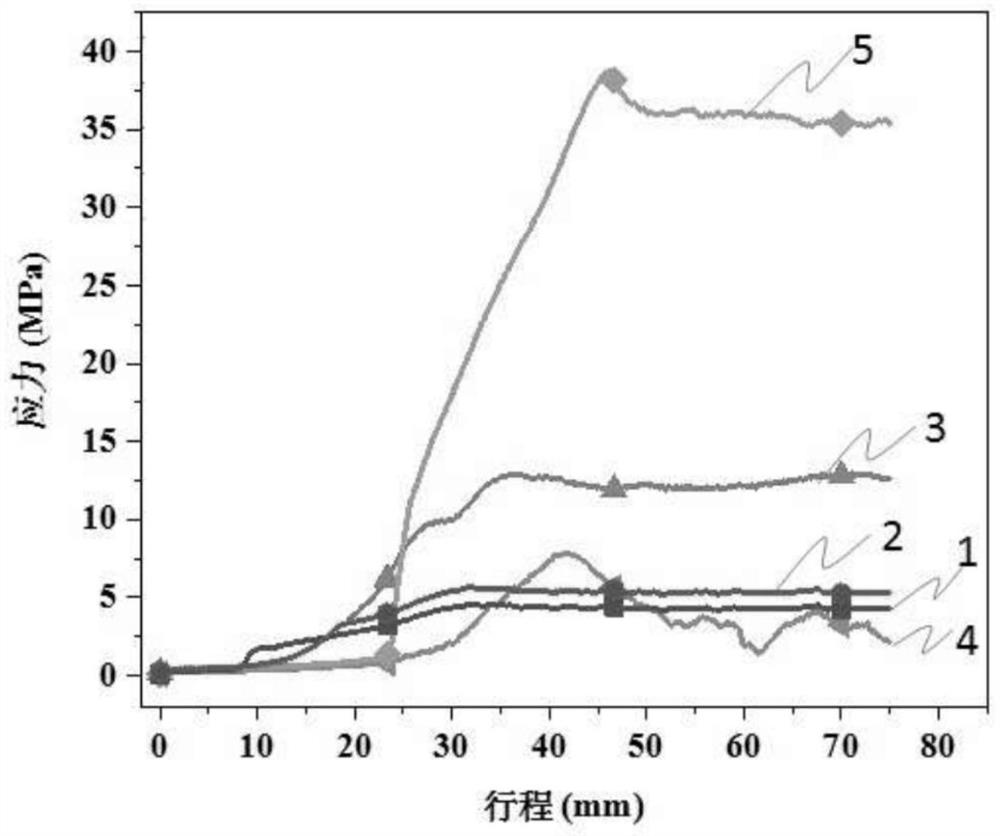

Image

Examples

Embodiment 1

[0032] The high-fluidity fluororesin slurry described in this embodiment and its preparation method, said method comprises the following steps:

[0033] a) Determination of solid content of PTFE resin stock solution:

[0034] Adopt density meter to measure the solid content of 1000g PTFE resin stoste to be 30wt%;

[0035] b) Pre-concentration:

[0036] The PTFE resin stock solution was placed in a 90°C oven and heated for 2h to layer the PTFE resin stock solution, and the fluororesin solution was separated from water with a pear-shaped fractionating flask to obtain 600g of PTFE resin pre-concentrate with a solid content of 50wt%.

[0037] c) addition of surfactant:

[0038] Add 0.225g C to the above PTFE resin pre-concentrate 3 f 7 OCF 2 CF 2 COONH 4 and 0.075g CF 3 O(CF 2 O) 4 CF 2 COOH is stirred by a four-blade stirrer to obtain a PTFE resin concentrate with good mechanical stability;

[0039] d) freezing:

[0040] Put the above-mentioned PTFE resin concentrate...

Embodiment 2

[0045] The high-fluidity fluororesin slurry described in this embodiment and its preparation method, said method comprises the following steps:

[0046] a) Determination of solid content of PTFE resin stock solution:

[0047] Adopt density meter to measure the solid content of 1000g PTFE resin stoste to be 30wt%;

[0048] b) Pre-concentration:

[0049] The PTFE resin stock solution was placed in a 60° C. oven and heated for 12 hours to layer the PTFE resin stock solution, and the fluororesin solution was separated from water with a pear-shaped fractionating flask to obtain 430 g of PTFE resin pre-concentrate with a solid content of 70 wt %;

[0050] c) addition of surfactant:

[0051] Add 2.1 g of CF to the above PTFE resin pre-concentrate 3 OCF (CF 3 )OCF(CF 3 )COOH and 0.9g C 2 f 5 OCF (CF 3 )OCF(CF 3 ) COOH, using four paddle stirrers to stir, obtain the better PTFE resin concentrated solution of mechanical stability;

[0052] d) freezing:

[0053] Put the above PT...

Embodiment 3

[0058] The high-fluidity fluororesin slurry described in this embodiment and its preparation method, said method comprises the following steps:

[0059] a) Determination of solid content of PTFE resin stock solution:

[0060] The solid content of the 1000g PTFE resin stock solution measured by a densitometer is 30wt.%.

[0061] b) Pre-concentration:

[0062] The PTFE resin stock solution was placed in a 75°C oven and heated for 8h to layer the PTFE resin stock solution, and the fluororesin solution was separated from water with a pear-shaped fractionating flask to obtain 460g of PTFE resin pre-concentrate with a solid content of 65wt.%.

[0063] c) addition of surfactant:

[0064] Add 0.5g CF to the above PTFE resin pre-concentrate 3 OCF (CF 3 )OCF(CF 3 )COOH and 1g C 2 f 5 OCF (CF 3 )OCF(CF 3 )COONH 4 , using a four-blade stirrer to stir to obtain a PTFE resin concentrate with good mechanical stability;

[0065] d) freezing:

[0066] Put the above-mentioned PTFE r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com