A gold-modified porous tin dioxide micro-nano sheet composite material and its preparation method and application

A technology of tin dioxide and composite materials, applied in the field of nanomaterials, can solve the problems of inability to control the microstructure of tin dioxide, and achieve the effects of high crystallinity, high sensitivity and responsiveness, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a gold-modified porous tin dioxide micro-nano sheet composite material, comprising the following steps:

[0047] A. Dissolve stannous chloride dihydrate in a mixed solution of ethylene glycol and water with a volume ratio of 1:5 to prepare 20 milliliters of 0.1M stannous chloride solution;

[0048] Dissolve sodium hydroxide in water to prepare 10 ml of 0.2M sodium hydroxide solution;

[0049] The two solutions were heated to 30°C, and the above-mentioned sodium hydroxide solution was added to the stannous chloride solution under magnetic stirring at a rotational speed of 50 rpm, and then continued to stir at 30°C for 3 minutes to obtain a mixed suspension. , stand for 48 hours at 30°C to obtain a white precipitate, filter and wash the white precipitate, and dry at 40°C for 24 hours to obtain basic stannous chloride micro-nano sheets;

[0050] B. The basic stannous chloride micro-nano sheet is calcined at 800 ° C for 0.5 hour, and after cooling, ...

Embodiment 2

[0053] A preparation method of a gold-modified porous tin dioxide micro-nano sheet composite material, comprising the following steps:

[0054] A, dissolving stannous chloride dihydrate in a mixed solution of ethylene glycol and water with a volume ratio of 1:10 to prepare 20 milliliters of 0.2M stannous chloride solution;

[0055] Dissolve sodium hydroxide in water to prepare 10 ml of 0.5M sodium hydroxide solution;

[0056] The two solutions were heated to 45°C, and the above-mentioned sodium hydroxide solution was added to the stannous chloride solution under magnetic stirring at a rotational speed of 80 rpm, and then continued to stir at 45°C for 8 minutes to obtain a mixed suspension. , stand for 45 hours at 45°C to obtain a white precipitate; filter and wash the white precipitate, and dry at 50°C for 20 hours to obtain basic stannous chloride micro-nano sheets;

[0057] B. The basic stannous chloride micro-nano sheet is calcined at 700 ° C for 0.5 hour, and after coolin...

Embodiment 3

[0060] A preparation method of a gold-modified porous tin dioxide micro-nano sheet composite material, comprising the following steps:

[0061] A, dissolving stannous chloride dihydrate in a mixed solution of ethylene glycol and water with a volume ratio of 1:15 to prepare 20 milliliters of 0.3M stannous chloride solution;

[0062] Dissolve sodium hydroxide in water to prepare 10 ml of 1.2M sodium hydroxide solution;

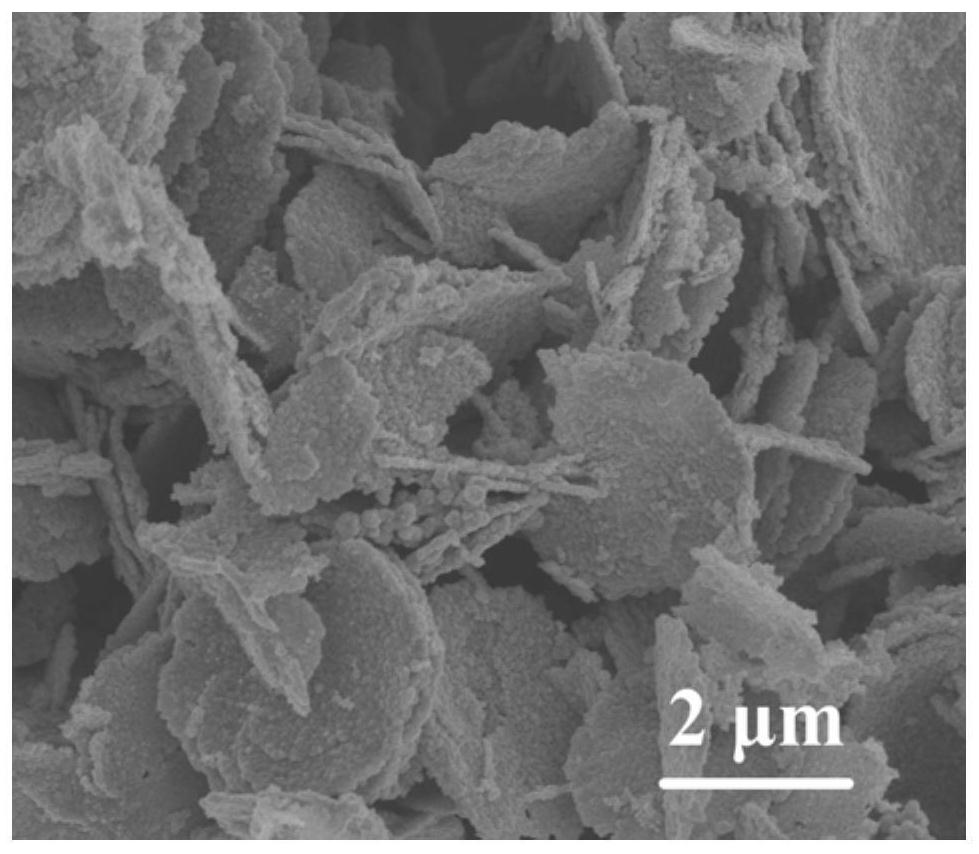

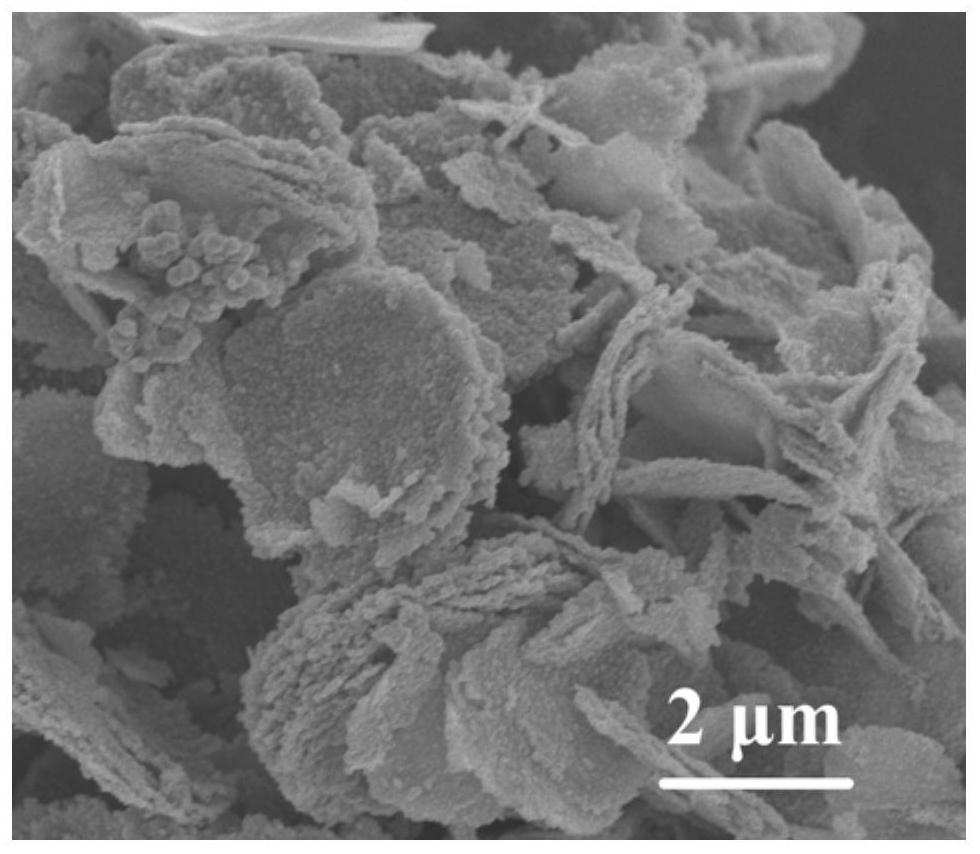

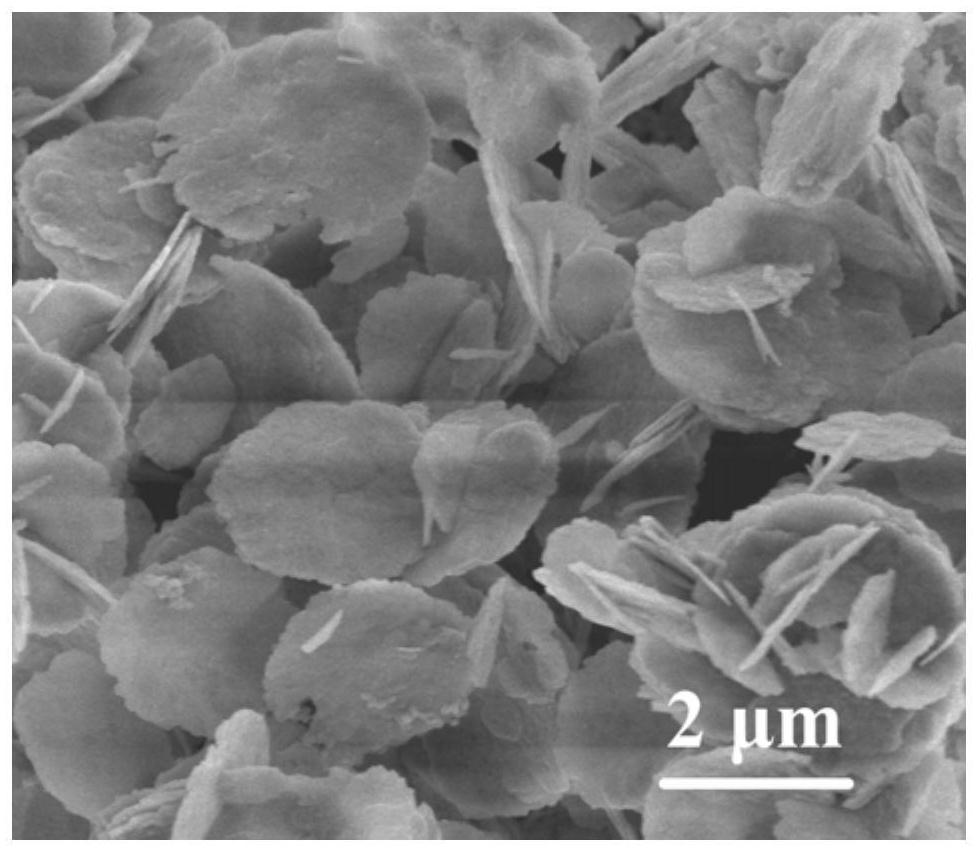

[0063] The two solutions were heated to 55°C, and the above-mentioned sodium hydroxide solution was added to the stannous chloride solution under magnetic stirring at a rotational speed of 120 rpm, and then continued to stir at 55°C for 10 minutes to obtain a mixed suspension. , aged at 55 °C for 48 hours to obtain a white precipitate; the white precipitate was filtered, washed, and dried at 60 °C for 18 hours to obtain basic stannous chloride micro-nano sheets. The SEM image is as follows image 3 It can be seen from the figure that it is a micro-nano sheet wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com