Evaluation method for lithium ion battery anode paste stability

A lithium-ion battery and positive electrode slurry technology, applied in flow characteristics, analysis materials, measurement devices, etc., can solve the problems of different, repeatability and accuracy of test results, etc., to achieve strong practicability, simple and fast operation steps, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

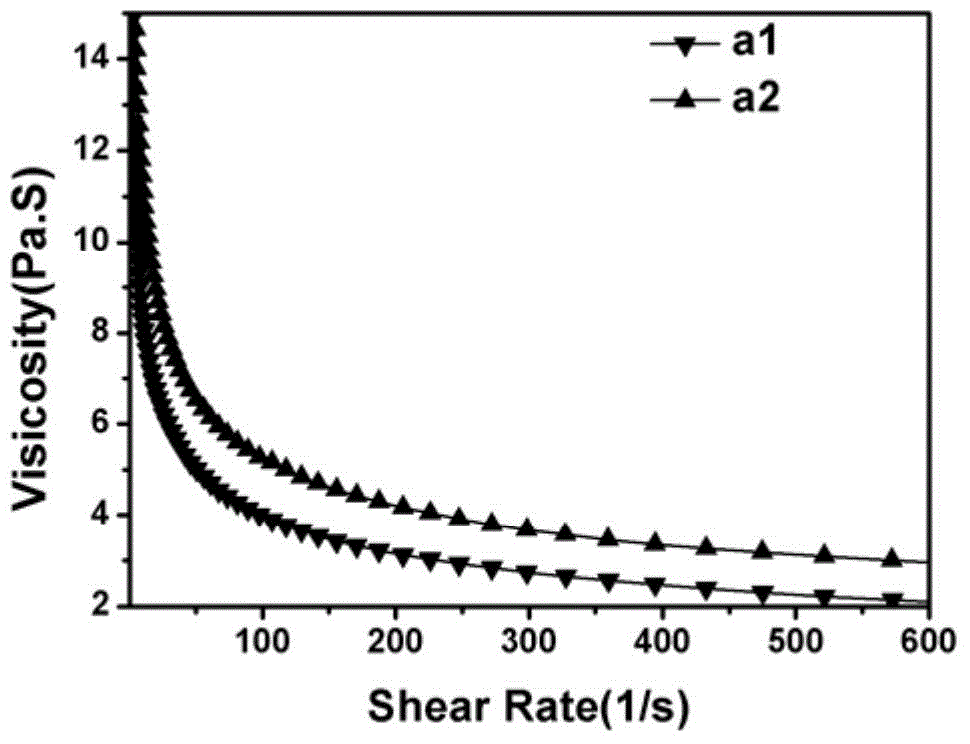

[0019] Weigh lithium iron phosphate, SP, KS-6 and PVDF, the mass percentage is 90:4:1:5, use NMP as the dispersing solvent, the theoretical solid content is set to 45%, and use XFZH planetary dispersion stirring vacuum according to the process requirements The mixer disperses and stirs at high speed for 2 hours. Take 100 ml of the mixed positive electrode slurry and fill it into a 50 ml acid burette. The upper opening is tightly sealed with a sealing plug and placed vertically at room temperature. After standing for 1 hour, use a rubber-tip dropper. The slurry at the upper end is sucked out, and the slurry at the lower end is discharged through the rotating glass piston, and the solid content and the shear rate-viscosity curve of the slurry are measured.

[0020] figure 1 It is a graph of the shear rate-viscosity change curve of the positive electrode slurry in Example 1 after standing for 1 hour, where a1 and a2 are the shear rate-viscosity change curve of the slurry at the uppe...

Embodiment 2

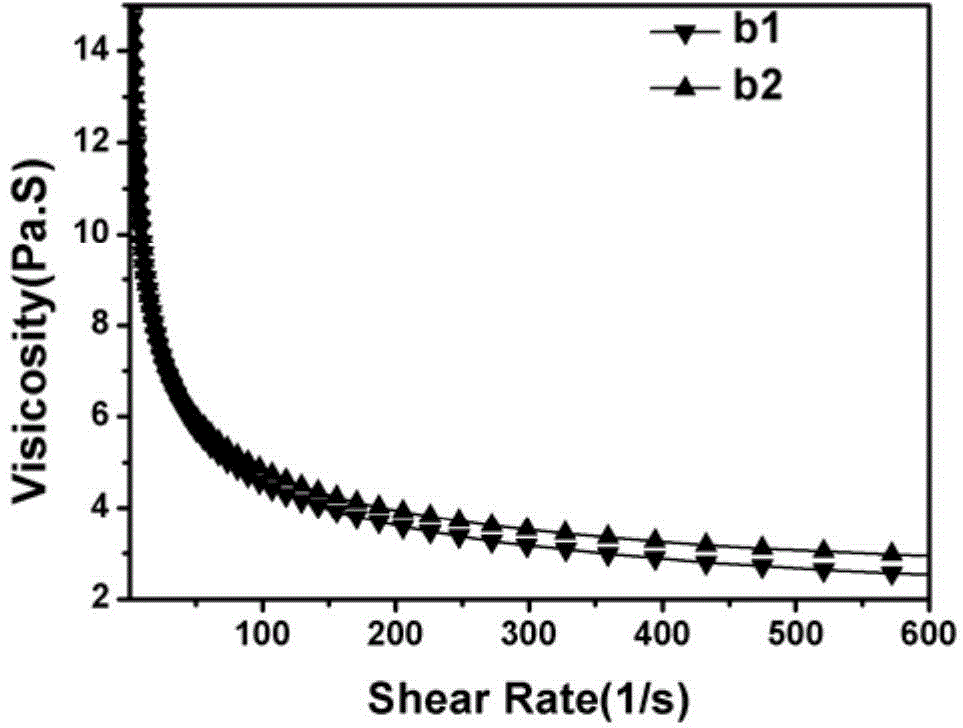

[0022] Weigh lithium iron phosphate, SP, KS-6 and PVDF, the mass percentage is 90:4:1:5, use NMP as the dispersing solvent, the theoretical solid content is set to 45%, and use XFZH planetary dispersion stirring vacuum according to the process requirements The mixer disperses and stirs at high speed for 4 hours. Take 100 ml of the mixed positive electrode slurry and fill it into a 50 ml acid burette. The upper opening is tightly sealed with a sealing plug and placed at room temperature to stand vertically. After standing for 3 hours, use a rubber-tip dropper. The slurry at the upper end is sucked out, and the slurry at the lower end is discharged through the rotating glass piston, and the solid content and the shear rate-viscosity curve of the slurry are measured.

[0023] figure 2 It is the shear rate-viscosity change curve of the positive electrode slurry in Example 2 after standing for 3 hours, where b1 and b2 are the shear rate-viscosity change curve of the slurry at the upp...

Embodiment 3

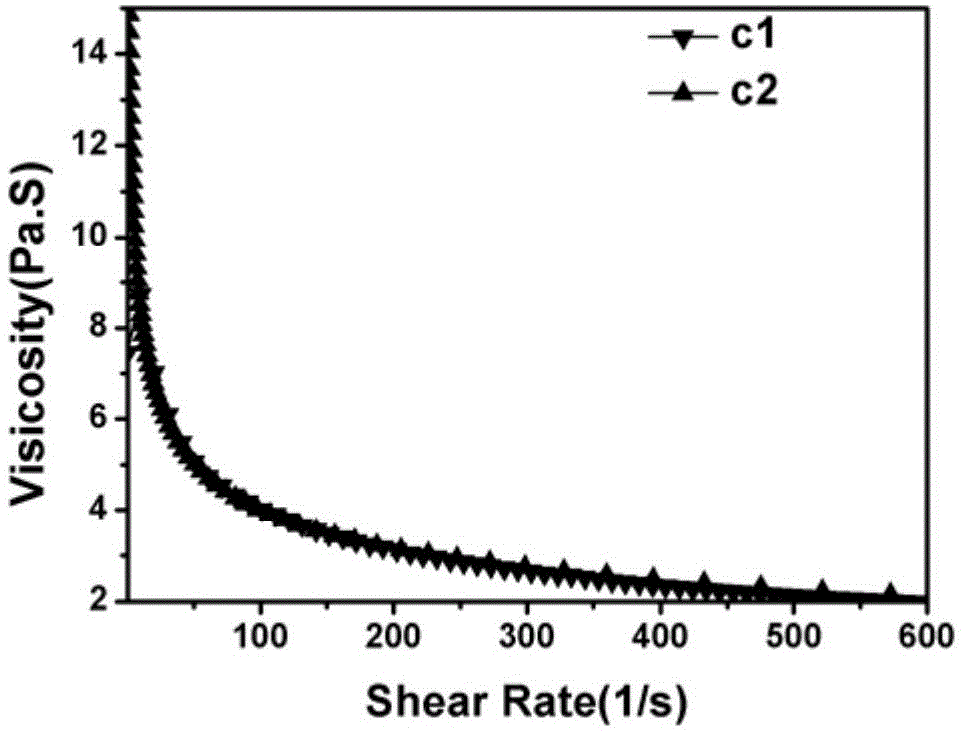

[0025] Weigh lithium iron phosphate, SP, KS-6 and PVDF, the mass percentage is 90:4:1:5, use NMP as the dispersing solvent, the theoretical solid content is set to 45%, and use XFZH planetary dispersion stirring vacuum according to the process requirements The mixer stirs at high speed for 6 hours. Take 100 ml of the mixed positive electrode slurry and fill it into a 50 ml acid burette. The upper opening is tightly sealed with a sealing plug and placed in a vertical stand at room temperature. After standing for 5 hours, use the glue head to drip. The pipe sucks out the slurry at the upper end, and discharges the slurry at the lower end through the rotating glass piston, and measures the solid content and shear rate-viscosity curve of the slurry.

[0026] image 3 It is the shear rate-viscosity change curve of the positive electrode slurry in Example 3 after standing for 5 hours, where c1 and c2 are the shear rate-viscosity change curve of the slurry at the upper and lower ends of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com