Method and device for measuring heat conductivity of quasi-one-dimensional conductive material

A technology of conductive materials and thermal conductivity, which is applied in the field of measuring the thermal conductivity of quasi-one-dimensional conductive materials, can solve the problems of difficult measurement and large thermal conductivity deviation, and achieve the effect of simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Utilize the measurement method and the device of quasi-one-dimensional conductive material thermal conductivity of the present invention to measure the thermal conductivity of platinum wire fiber, concrete steps and measurement result are as follows:

[0089] 1) Fix the platinum wire to the test sample stage:

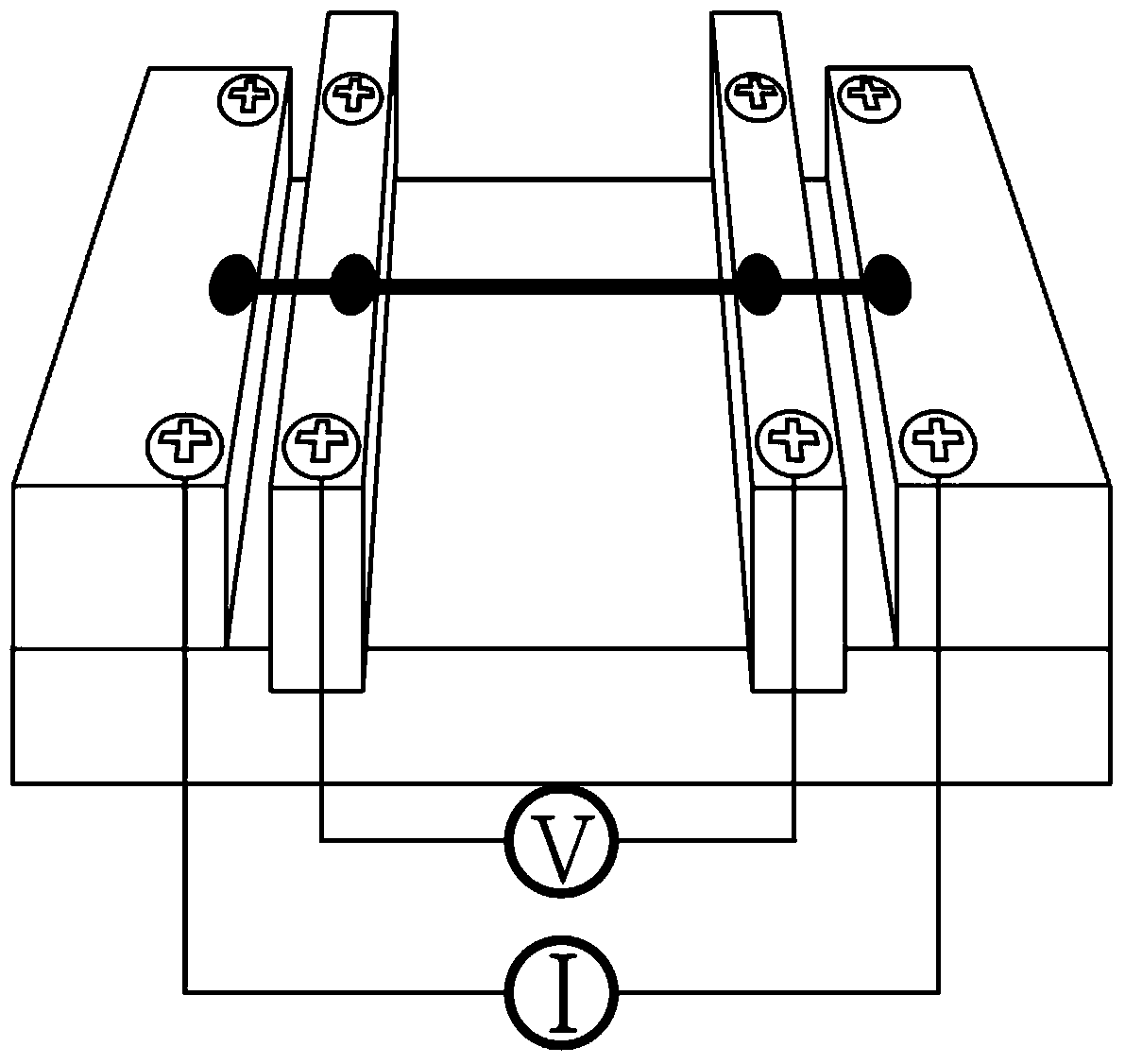

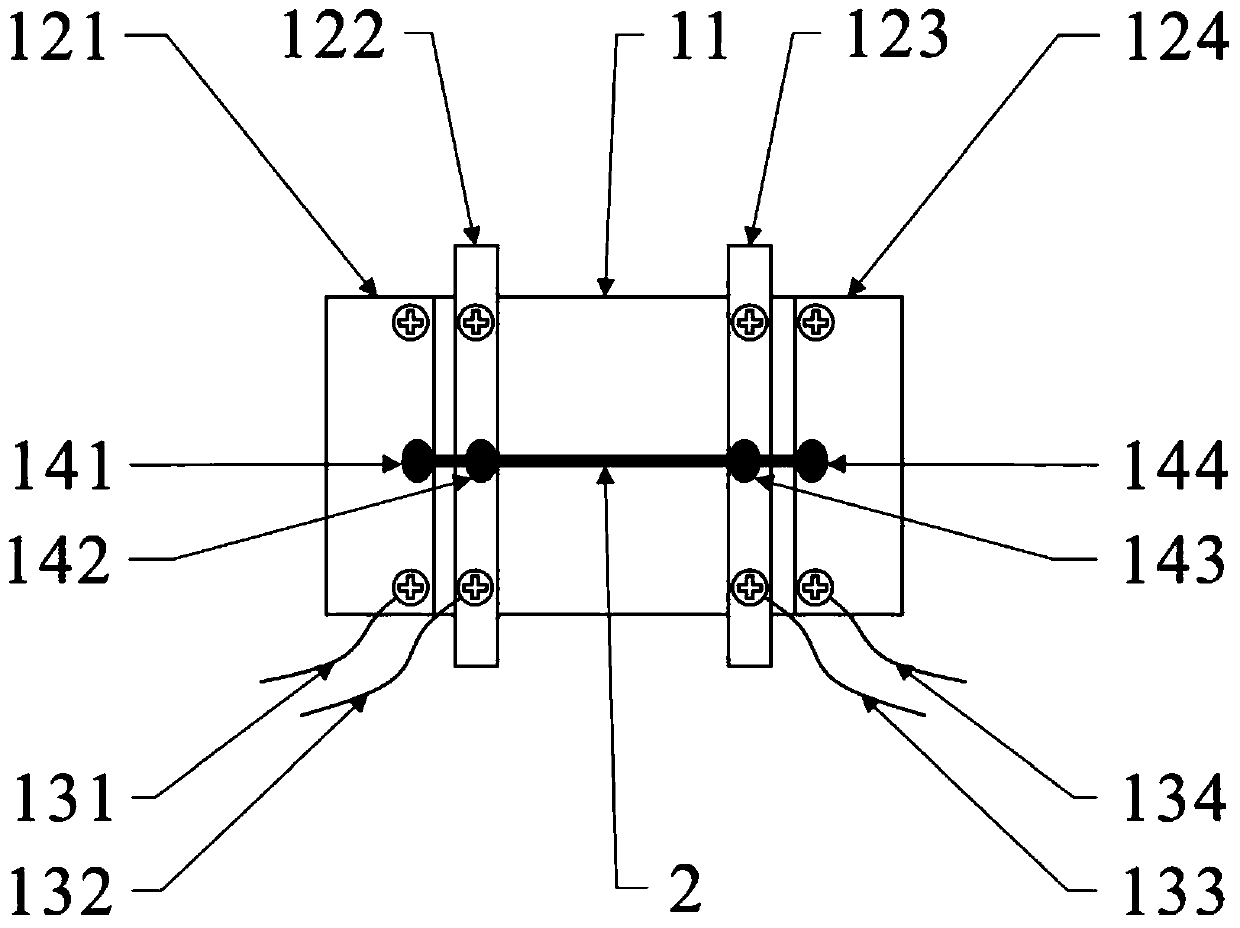

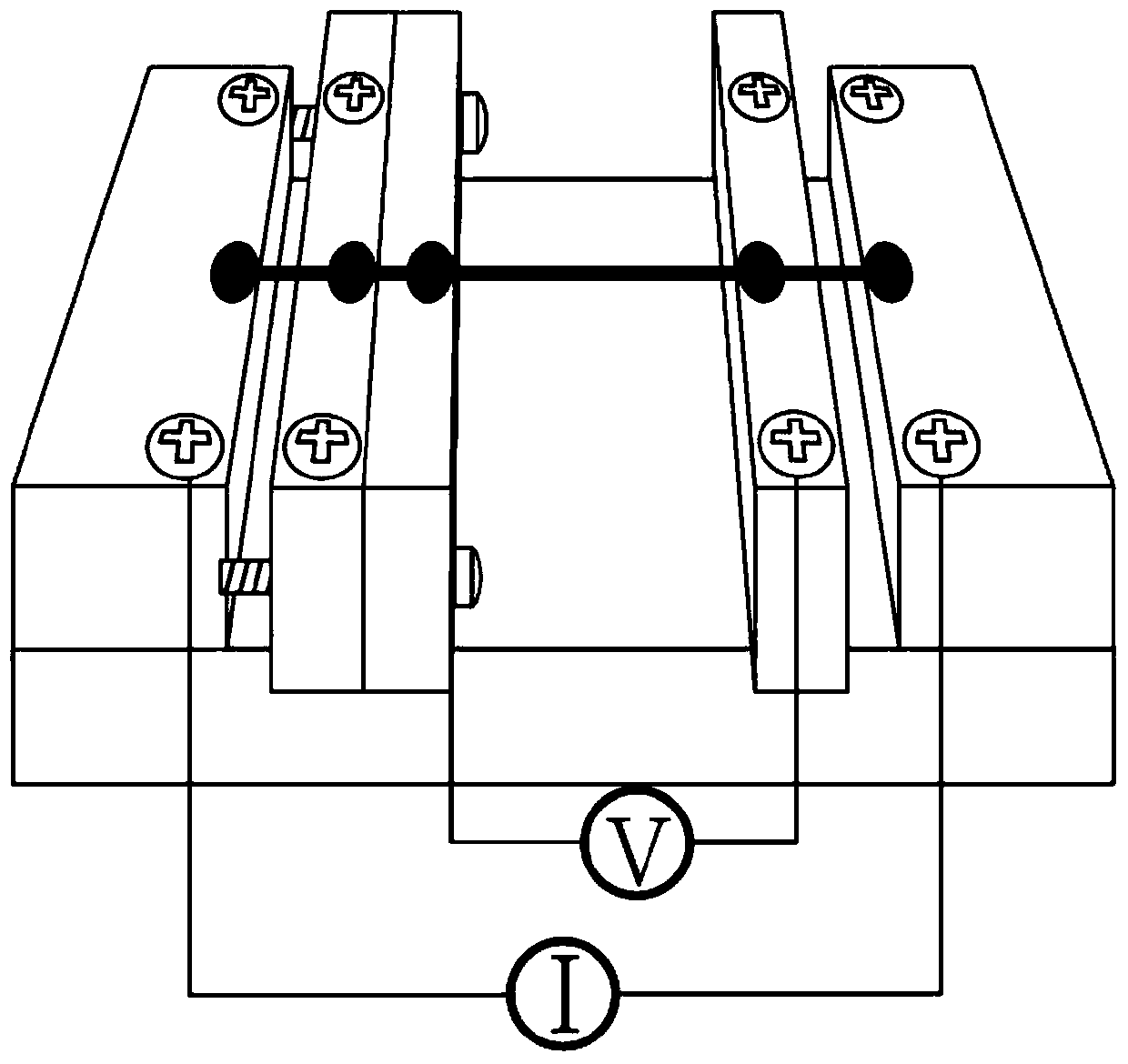

[0090] see figure 1 and figure 2 The schematic diagram and top view of the test sample platform are shown. The platinum wire sample 2 is fixed on the four copper electrodes 121-124 in the sample table 1 with high-purity silver glue, and the four silver glue fixing points 141-144 keep the platinum wire in good electrical and thermal contact with the heat sink. The middle section of the sample is suspended in the air, and the copper electrode is connected to four lead wires 131-134 for measuring the resistance of the suspended section in the middle of the sample by the four-electrode method to avoid the influence of contact resistance.

[0091] 2) Obtain platin...

Embodiment 2

[0102] The method and device for measuring the thermal conductivity of a quasi-one-dimensional conductive material of the present invention are used to measure the thermal conductivity of a red copper film.

[0103] 1) Fix the red copper thin film to the test sample platform, and the specific operation is the same as step 1) in Example 1.

[0104] 2) Obtain the size information of the copper film:

[0105] The thickness H was measured with a surface topography instrument. Under an optical microscope, measure the length L and width W of the middle suspended segment. Take the average value of multiple measurements L=19.2mm, W=1.03mm, H=20μm, and the corresponding cross-sectional area S=W×H.

[0106] 3) Load the sample platform to the sample chamber, the specific operation is the same as step 3) of Example 1.

[0107] 4) Measure the rate of change B of the resistance of the copper film suspended section with temperature.

[0108] Concrete operation is with the step 4) of embo...

Embodiment 3

[0113] The thermal conductivity of the copper fiber at 400K is measured by the method and device for measuring the thermal conductivity of the quasi-one-dimensional conductive material of the present invention.

[0114] 1) Fix the red copper fiber to the test sample platform, and the specific operation steps are the same as step 1) in Example 1.

[0115] 2) Obtain the size information of the copper fiber:

[0116] Under an optical microscope, measure the length L and diameter D of the middle suspended segment. Take the average value of multiple measurements L=19.8mm, D=134μm.

[0117] 3) Load the sample platform to the sample chamber, the specific operation steps are the same as step 3) of Example 1.

[0118] 4) Measure the change rate B of the resistance of the copper fiber suspension section with temperature.

[0119] Concrete operation steps are with embodiment 1 step 4). Fit a series of temperature and resistance values obtained from the records into an R-T curve, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Average resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com