Preparation of transparent conducting film based on nano-silver wires and caboxylated carbon nano-materials

A technology of transparent conductive film and carbon nanomaterials, which is applied to the conductive layer on the insulating carrier, cable/conductor manufacturing, circuit, etc., can solve the problems of complex conductivity and light transmittance in the preparation of transparent conductive films, and achieve transparency and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

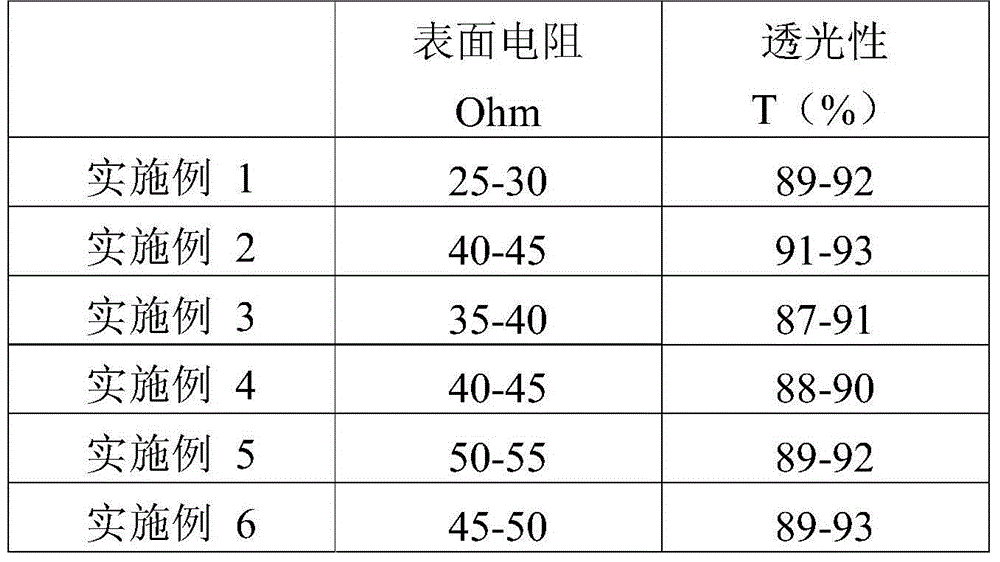

Embodiment 1

[0030] The preparation of a transparent conductive film based on nano silver wires and carboxylated carbon nanomaterials comprises the following steps:

[0031] (1) In a 250mL single-neck round bottom flask equipped with a magnetic stirrer, add 3g of dry single-armed carbon nanotubes and 15mL of a mixed acid of 60wt% concentrated nitric acid and 45mL of 98wt% concentrated sulfuric acid, and use 150W ultrasonic treatment for 30min before loading The upper spherical condenser and the tail gas absorption tube were heated to 120°C, stirred and refluxed for 2 hours; after the reaction, diluted with 800mL deionized water, filtered with a small 0.22μm mixed fiber microporous membrane, and deionized water Repeated washing several times until neutral, vacuum drying at 60°C for 24 hours to obtain carboxylated carbon nanomaterials;

[0032] (2) In a 150mL beaker, add 20mg of the carboxylated carbon nanomaterial prepared in step (1), then add 50mL of ethanol, 150W ultrasonic dispersion fo...

Embodiment 2

[0036] The preparation of a transparent conductive film based on nano silver wires and carboxylated carbon nanomaterials comprises the following steps:

[0037] (1) In a 100mL single-necked round bottom flask equipped with a magnetic stirrer, add 2g of dry graphene and 10mL of a mixed acid of 60wt% concentrated nitric acid and 30mL of 98wt% concentrated sulfuric acid. Condenser tube and tail gas absorption tube, heated to 120°C, stirred and refluxed for 4 hours; after the reaction, diluted with 400mL deionized water, filtered with a small 0.22μm mixed fiber microporous filter membrane, washed repeatedly with deionized water Secondary to neutral, vacuum drying at 60°C for 24 hours to obtain carboxylated carbon nanomaterials;

[0038] (2) In a 150mL beaker, add 10mg of the carboxylated carbon nanomaterial prepared in step (1), then add 50mL of ethanol, 150W ultrasonic dispersion for 10 minutes, remove the bottom precipitate after standing for 12 hours, and then add Add 50mL of ...

Embodiment 3

[0041] The preparation of a transparent conductive film based on nano silver wires and carboxylated carbon nanomaterials comprises the following steps:

[0042](1) In a 250mL single-necked round-bottomed flask equipped with a magnetic stirrer, add 3g of dry multi-armed carbon nanotubes and a mixed acid of 15mL 60wt% concentrated nitric acid and 45mL 98wt% concentrated sulfuric acid, and use 150W ultrasonic treatment for 30min before loading The upper spherical condenser and tail gas absorption tube are heated to 120°C, stirred and refluxed for 24 hours. After the reaction, dilute with 800mL deionized water, filter with a small 0.22μm mixed fiber microporous filter membrane, and deionized water Repeated washing several times until neutral, vacuum drying at 60°C for 24 hours to obtain carboxylated carbon nanomaterials;

[0043] (2) In a 150mL beaker, add 15mg of the carboxylated carbon nanomaterial prepared in step (1), then add 50mL of ethanol, 150W ultrasonic dispersion for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com