Airbag Fabric

A fabric and airbag technology, applied in the processing of textile materials, marking of textile materials, local processing of textile materials, etc., can solve the problems of no representation, labor/time, misuse, etc., and achieve easy tracking and resource recovery. , the effect of easy production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

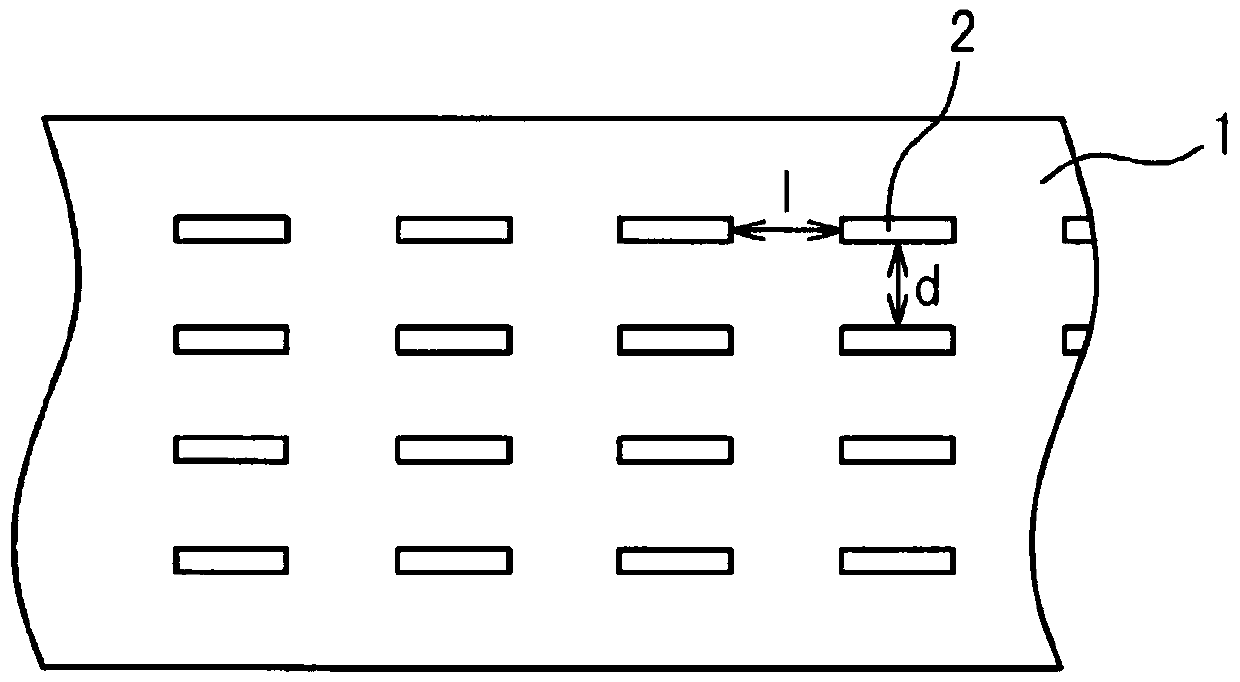

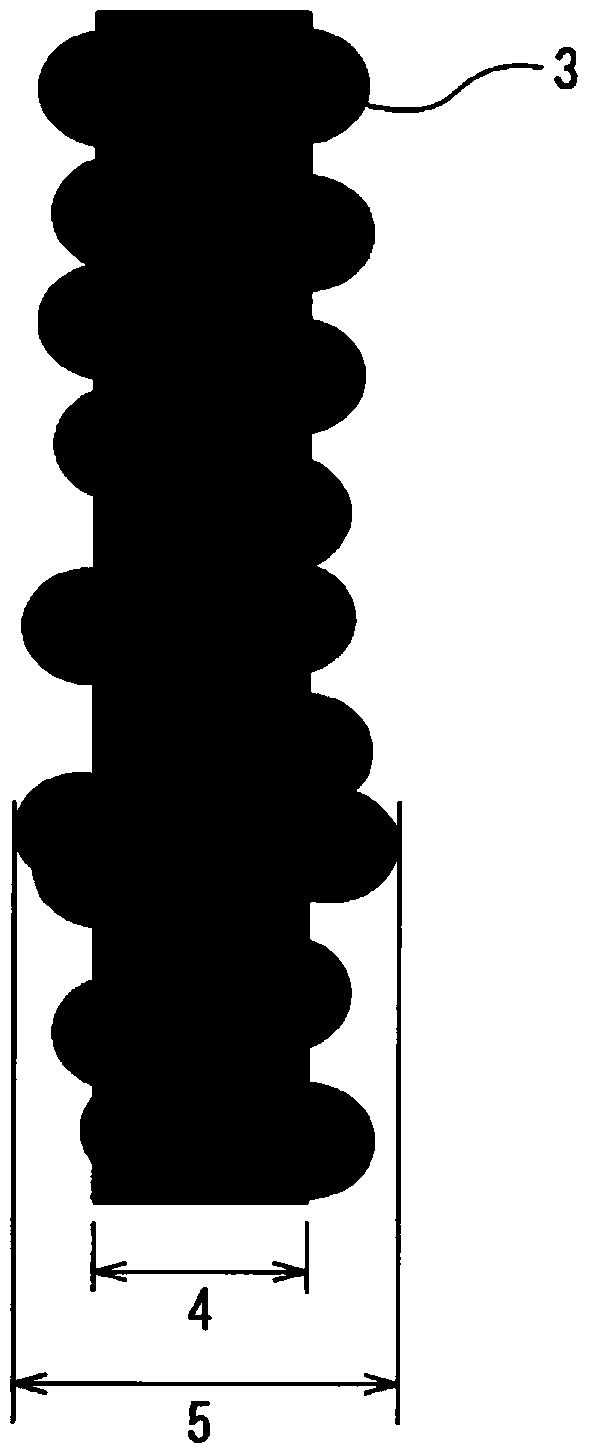

[0087] As the weaving yarn, a polyhexamethylene adipamide fiber having a fineness of 470 dtex and 136 filaments was used. The tanδ(max) of this fiber was 0.075, the Tmax was 122°C, and the ratio S was 0.00061 [1 / °C]. As a warp yarn, it is arranged in parallel without twisting and sizing to make a warp beam. For the weft yarn, it is wound without twist and size, and supplied directly from the bobbin. A plain weave is produced using a water jet loom. The entry reed of warp yarn is 2 / reed teeth. The obtained fabric was dried at 60° C. without refining so that the moisture content of the fabric was 3%. Next, heat-setting processing was performed using a pin tenter under the conditions of a heating temperature of 200° C. and a 1-minute dwell, with an overfeed of 0% and a neck-in of 2%. The fabric density of the finished fabric is 53.0 / 2.54cm in warp and weft. The oil content was 0.15% by weight.

[0088] For the cloth, an inkjet printer utilizing 60 micron nozzles used ethano...

Embodiment 2

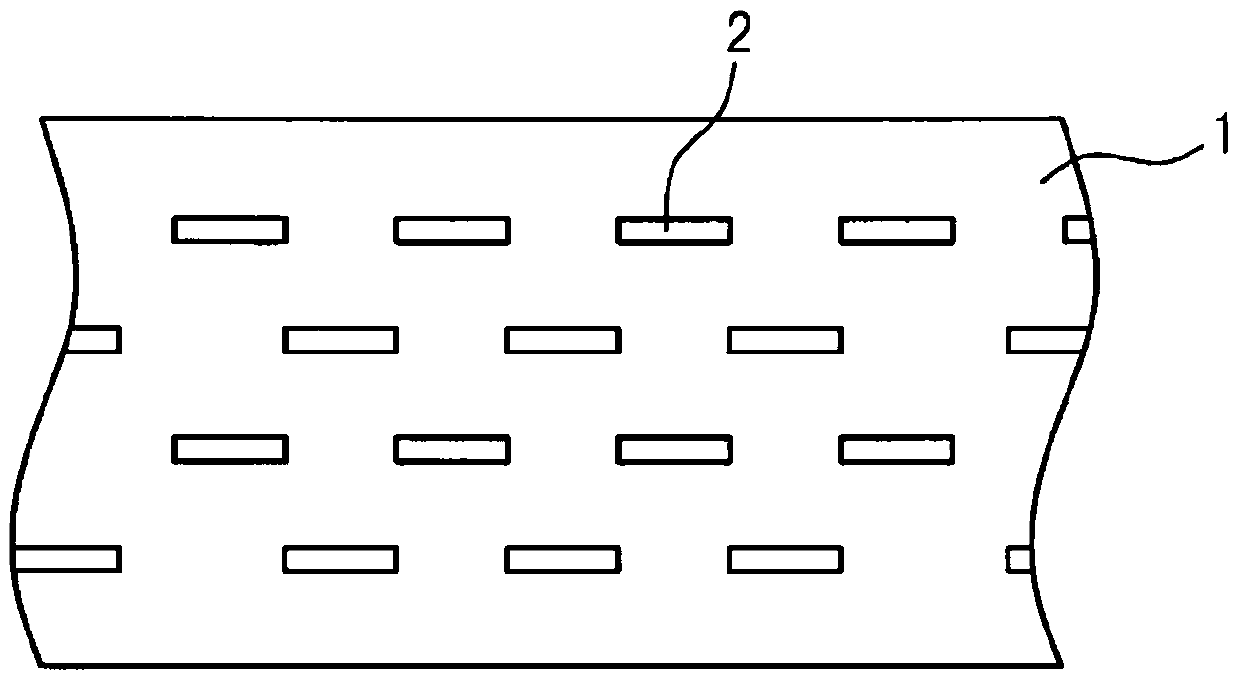

[0090] In Example 1, heat calendering was performed instead of heat setting with a pin tenter. The hot rolling process was performed at a feed rate of 18 m / min, a metal roll temperature of 200° C., and a pressure of 600 N / cm. Regarding the upper and lower calender rolls that sandwich the fabric, the upper metal roll for heating has a diameter of 12 cm, and the lower roll has a paper surface of 24 cm in diameter, and the surface speed is the same speed up and down. The Shore D hardness of the paper roll surface was 65. The fabric density of the finished fabric is 53.0 / 2.54cm in warp and weft. The oil content was 0.15% by weight.

[0091] A barcode was printed by inkjet in the same manner as in Example 1 on the surface smoothed by heating calender roll processing. The exudation index N was 0.1, which was good. The print quality evaluation of the printed surface by the barcode checker (opening diameter 10 / wavelength 660) was rank A-3.6, and it was good. The reading printing ...

Embodiment 3

[0093] In Example 1, after weaving and drying, at 20g / m 2 Finishing is performed by applying two-component curable silicone with no color pigment added, and vulcanizing by heating at 180°C for 2 minutes. The fabric density adjustment on the loom was carried out, and the fabric density of the finished cloth became 49.0 warp and weft averages / 2.54cm. The oil content was 0.15% by weight.

[0094] A barcode was printed on the non-coated surface by inkjet in the same manner as in Example 1. The exudation index N was 0.8. The print quality evaluation of the printed surface by the barcode checker (opening diameter 10 / wavelength 660) was rank B-2.8, and it was good. The read print quality of the non-printed surface was grade B-2.5, good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com