Automatic grinding polishing system

A grinding and automatic technology, applied in the direction of grinding/polishing equipment, grinding machines, instruments, etc., can solve the problems of low processing yield, high labor intensity, lack of flexibility, etc., and achieve low manufacturing and processing costs, efficient and accurate processing , the effect of convenient expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

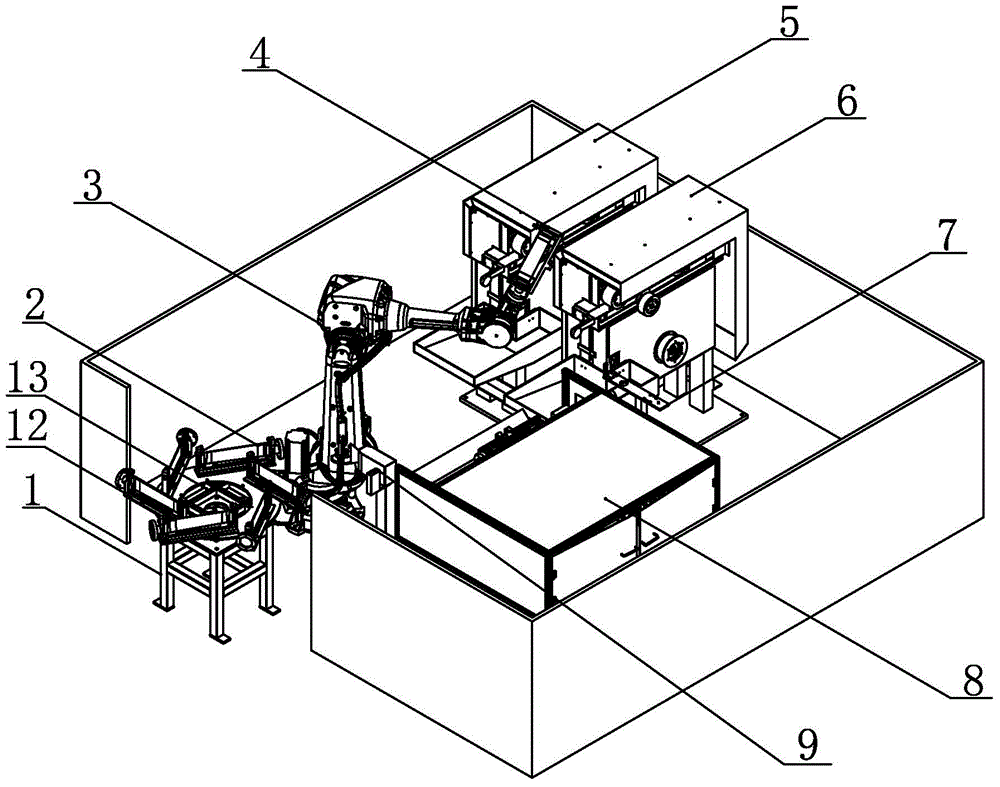

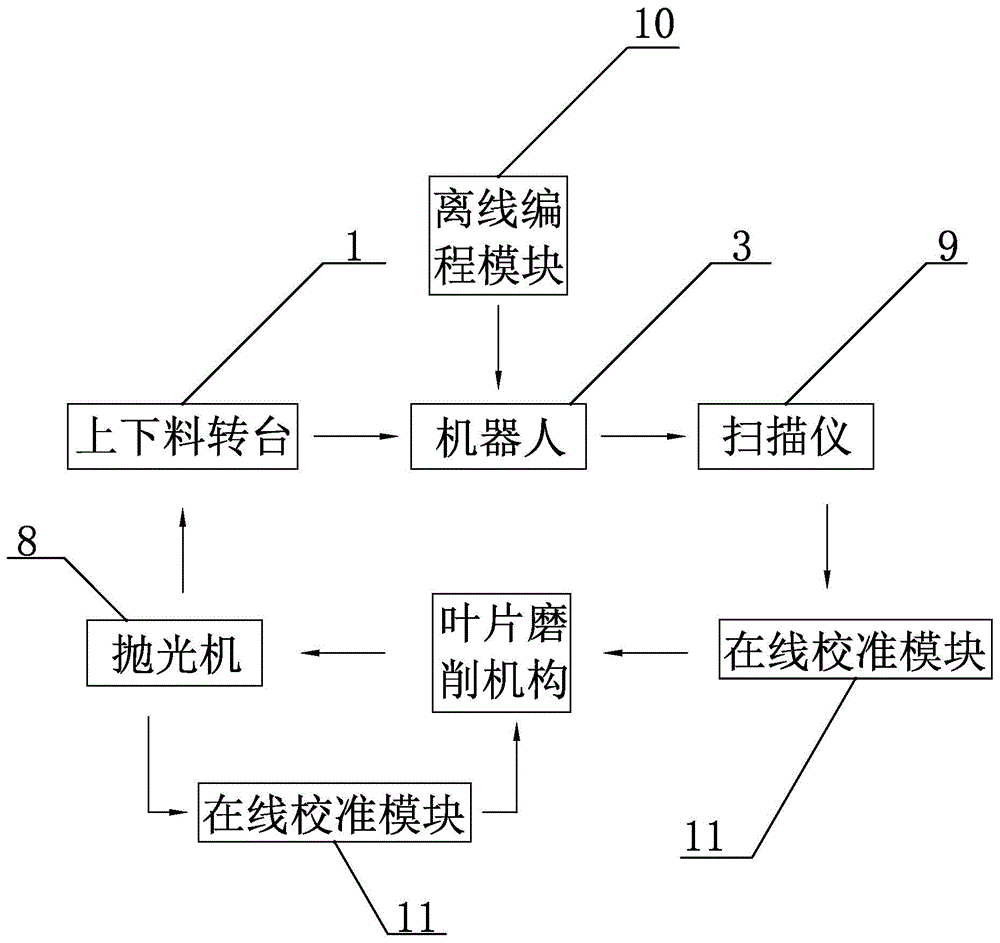

[0021] Such as figure 1 As shown, an automatic grinding and polishing system of the present invention includes a loading and unloading turntable 1, a robot 3, a blade grinding mechanism, a buffer table 7, a polishing machine 8, a scanner 9 and a software control system. Wherein the loading and unloading turntable 1 comprises a base, on which a rotating platform 13 is movably installed, and a plurality of workpiece installation clamping positions 12 are uniformly arranged around the rotating platform 13. When the rotating platform 13 rotates, each workpiece 2 can be rotated to the processing area in turn. The robot 3 is used to transport the workpiece 2 to the designated location for processing in the corresponding process. The robot 3 is an industrial six-axis robot. The robot arm is equipped with a quick-change fixture 4, which is used to clamp the workpiece 2. The blade grinding mechanism is used to perform the grinding process. The blade grinding mechanism includes a fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com