Equipment for fluidization production of active carbon

A technology for the production of activated carbon and fluidization, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of low output of unit equipment, high energy consumption of activated carbon, high production cost, etc., and achieve shortened activation time and low production cost Low, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions and illustrations therein are essentially for illustration rather than for limit the invention.

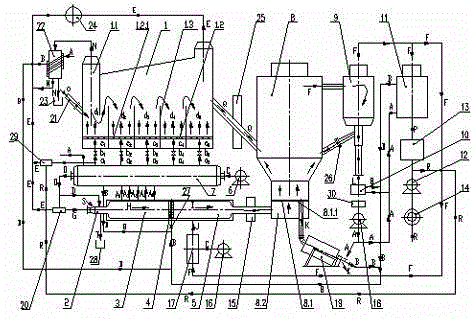

[0039] Such as figure 1 As shown, a kind of equipment of fluidized activated carbon production comprises: carbonization furnace and activation furnace, described carbonization furnace is a kind of multi-slot carbonization furnace 1, and described activation furnace is a kind of superheated steam activation furnace 8, and described multiple The tank carbonization furnace 1 is connected to the segmented air gas-water heat exchanger 7, the segmented air gas-water heat exchanger 7 is connected to the ash fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com