Oil resistant seal ring and preparation method thereof

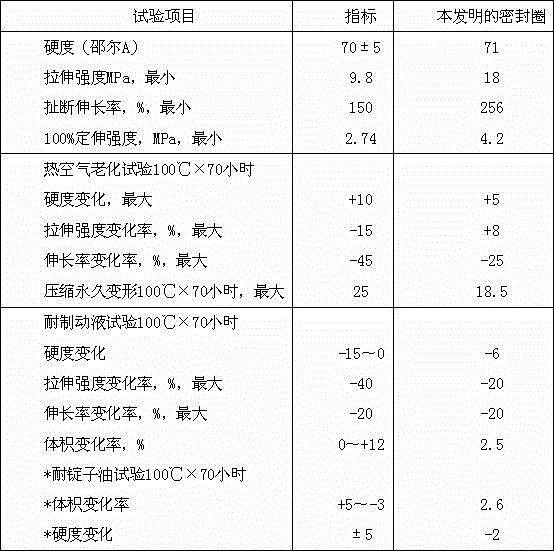

An oil-resistant sealing ring and accelerator technology, used in the field of rubber products, can solve the problems of large geometric size tolerance, high three-pack products, decreased strength, etc., to achieve small compression permanent deformation, solve oil leakage, and large elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of oil-resistant sealing ring, its component content ratio is by weight:

[0030] 100 parts of nitrile rubber 220S with high acrylonitrile content;

[0031] Quickly extrude carbon black N550 for 70 minutes;

[0032] Polyether type cold-resistant plasticizer TP-95 8 parts;

[0033] The parts by weight of accelerator are 4.6 parts, which are respectively 1.0 part of TMTD, 1.0 part of TETD, 0.6 part of DTDM, and 2 parts of CZ;

[0034] The parts by weight of antioxidant are 3.5 parts, which are respectively 1.5 parts of RD and 2 parts of 4010NA;

[0036] Active agent stearic acid 1 part;

[0037] 0.56 parts of vulcanizing agent sulfur;

[0038] Operation aid TM-80 1.1 parts.

Embodiment 2

[0039] Embodiment 2: a kind of oil-resistant sealing ring, its component content ratio is by weight:

[0040] 100 parts of nitrile rubber 220S with high acrylonitrile content;

[0041] Quickly extrude 75 parts of carbon black N550;

[0042] Polyether type cold-resistant plasticizer TP-95 10 parts;

[0043] The parts by weight of accelerator are 5 parts, respectively 1.1 parts of TMTD, 1.2 parts of TETD, 0.6 parts of DTDM, and 2.1 parts of CZ;

[0044] The weight portion of antioxidant is 4 parts, is respectively 2 parts of RD, 2 parts of 4010NA;

[0046] 1.5 parts of active agent stearic acid;

[0047] 0.6 parts of vulcanizing agent sulfur;

[0048] Operation aid TM-80 1.5 parts.

Embodiment 3

[0049] Embodiment 3: A kind of preparation method of oil-resistant sealing ring, completes batching according to the rubber process formula weight ratio of embodiment 1, comprises the following steps:

[0050] Step 1: Mixing

[0051] Put the nitrile rubber into the internal mixer and press for 1 to 2 minutes, then add zinc oxide, stearic acid, sulfur, anti-aging agent and operating aids and press for 2 to 3 minutes, then add carbon black and press for 6 to 7 minutes. Minutes, finally add plasticizer and knead for 2 to 3 minutes, mixing temperature 105°C; deglue temperature 135°C, after the deglue and lower sheet cool down, add accelerator on the open mill at a low temperature below 50°C, and make triangular bags for 3~ 4 times, thin pass 2 to 3 times, and the next piece is cooled and stored for later use;

[0052] Step Two: Extrusion Process

[0053] The head temperature of the precision preforming machine is adjusted to 55°C, and the die temperature is 70°C. While extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com