Polytetrafluoroethylene material and preparation method therefor

A technology of polytetrafluoroethylene and basic materials, applied in the field of polytetrafluoroethylene materials and its preparation, can solve the problems of irreparable creep property of polytetrafluoroethylene, reduction of tensile ductility of raw materials, reduction of service life of products, etc. , to achieve superior self-lubricating performance, high fatigue resistance, and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

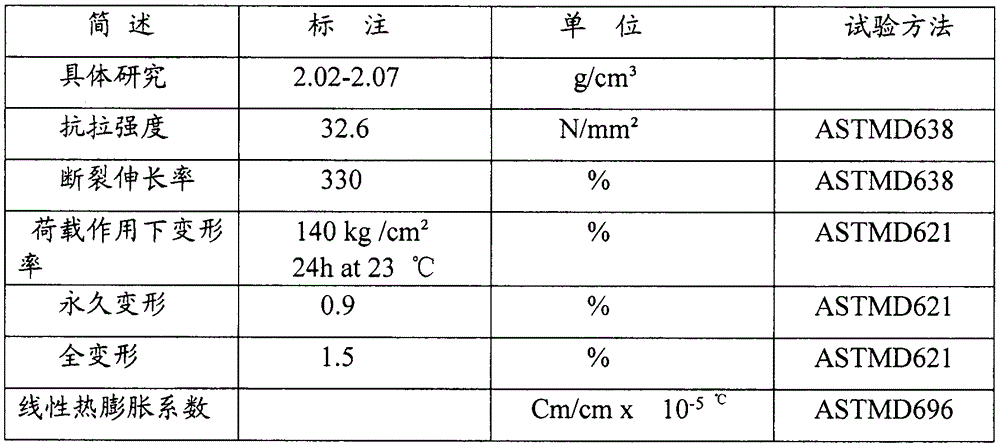

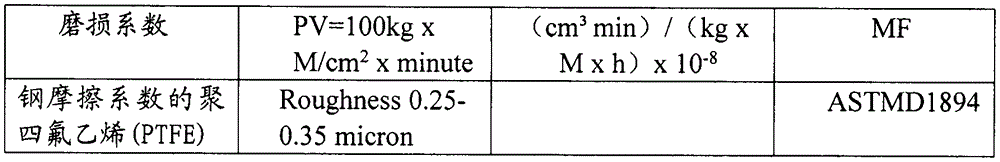

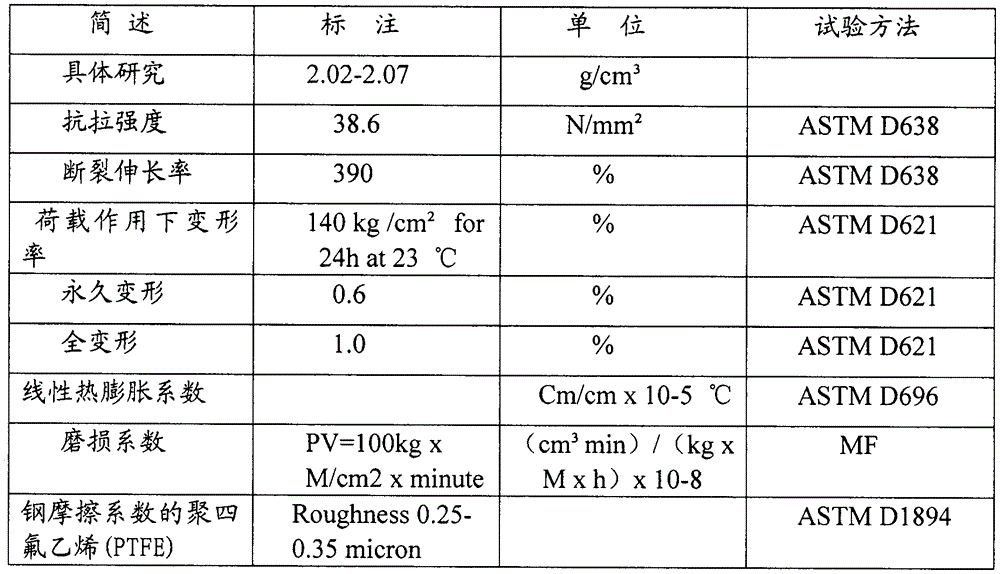

Examples

Embodiment 1

[0018] A polytetrafluoroethylene material is composed of the following components by weight: 6 parts of polytetrafluoroethylene, 0.8 part of molybdenum disulfide, 0.5 part of carbon fiber and 0.5 part of p-polystyrene.

Embodiment 2

[0020] A polytetrafluoroethylene material is composed of the following components by weight: 7 parts of polytetrafluoroethylene, 1.2 parts of molybdenum disulfide, 2.5 parts of carbon fiber and 2.5 parts of p-polystyrene.

Embodiment 3

[0022] A polytetrafluoroethylene material is composed of the following components by weight: 6 parts of polytetrafluoroethylene, 1 part of molybdenum disulfide, 1.5 parts of carbon fiber and 1.5 parts of p-polystyrene.

[0023] The materials in the above-mentioned Examples 1, 2, and 3 are prepared according to the following steps:

[0024] Step S1, first drying the p-polyphenylene at a high temperature of 300 degrees Celsius for 2 hours, and drying the carbon fiber at 260 degrees Celsius for 2 hours for later use;

[0025] In step S2, the two materials of para polyphenylene and carbon fiber dried in step S1 are mixed with molybdenum disulfide, put into the base material of polytetrafluoroethylene powder, and the high-speed mixing time is 30 seconds;

[0026] Step S3, adding a titanate coupling agent to the mixture obtained in step S2, and mixing again for 1 minute to obtain the material.

[0027] When mixing in step S2 and step S3, it is necessary to control the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com