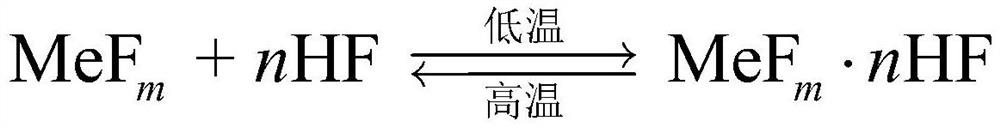

Hydrogen fluoride adsorbent as well as preparation method and application thereof

A hydrogen fluoride and adsorbent technology, applied in the field of hydrogen fluoride adsorbent and its preparation, can solve the problems of increasing the usage of fresh water in enterprises and being uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

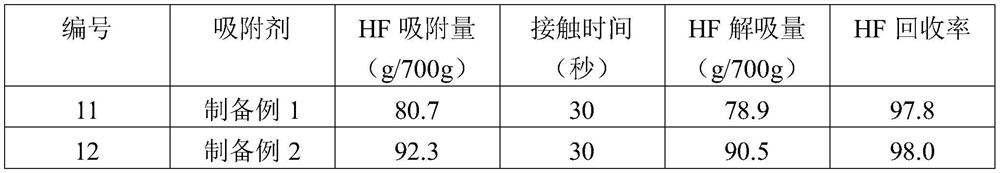

preparation example 1

[0031] Weigh 25kg of polyacrylonitrile, 12.5kg of sodium fluoride, and 12.5kg of potassium fluoride, mix them evenly, take them out and use a mortar to crush them into powders of about 80 meshes, extrude them with an extruder, and cut them into Φ4mm-6mm lengths. 6mm ~ 8mm particles, put into the tube furnace for pre-oxidation and carbonization.

[0032] Adsorbent preparation example 2

[0033] Weigh 25kg of polyacrylonitrile, 12.5kg of sodium fluoride, and 12.5kg of potassium bifluoride, mix them evenly, take them out and use a mortar to crush them into powders of about 80 meshes, extrude them with an extruder, and cut them into Φ4mm-6mm lengths. 6mm ~ 8mm particles, put into the tube furnace for pre-oxidation and carbonization.

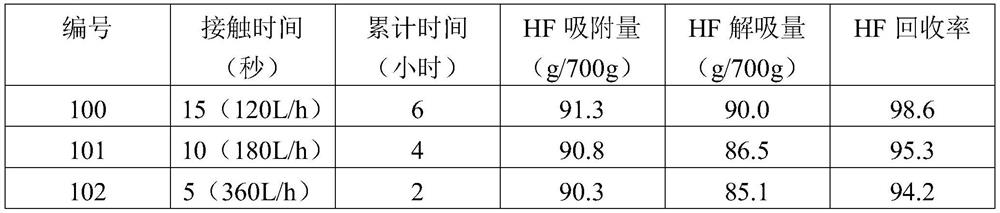

[0034] Adsorbent Adsorption Application Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com