Preparation method of rare earth element Sm-doped GaN nano wire

A technology of rare earth elements and nanowires, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost and complicated preparation process, and achieve low environmental pollution, simple process, and easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

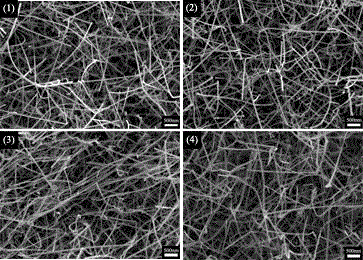

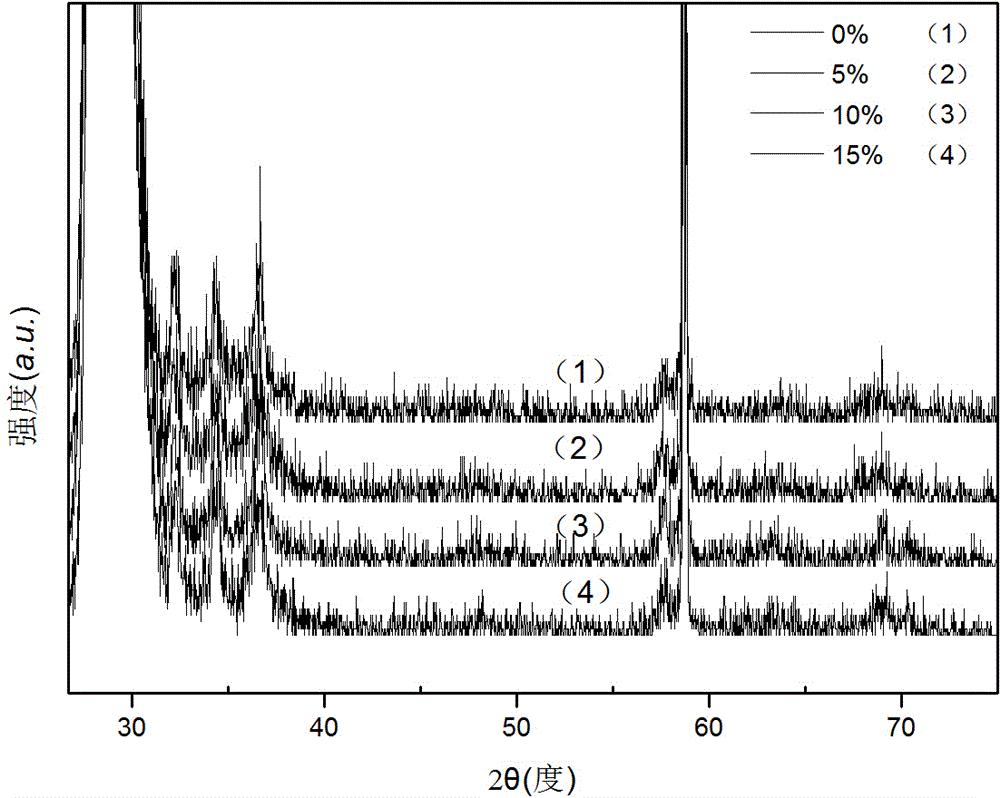

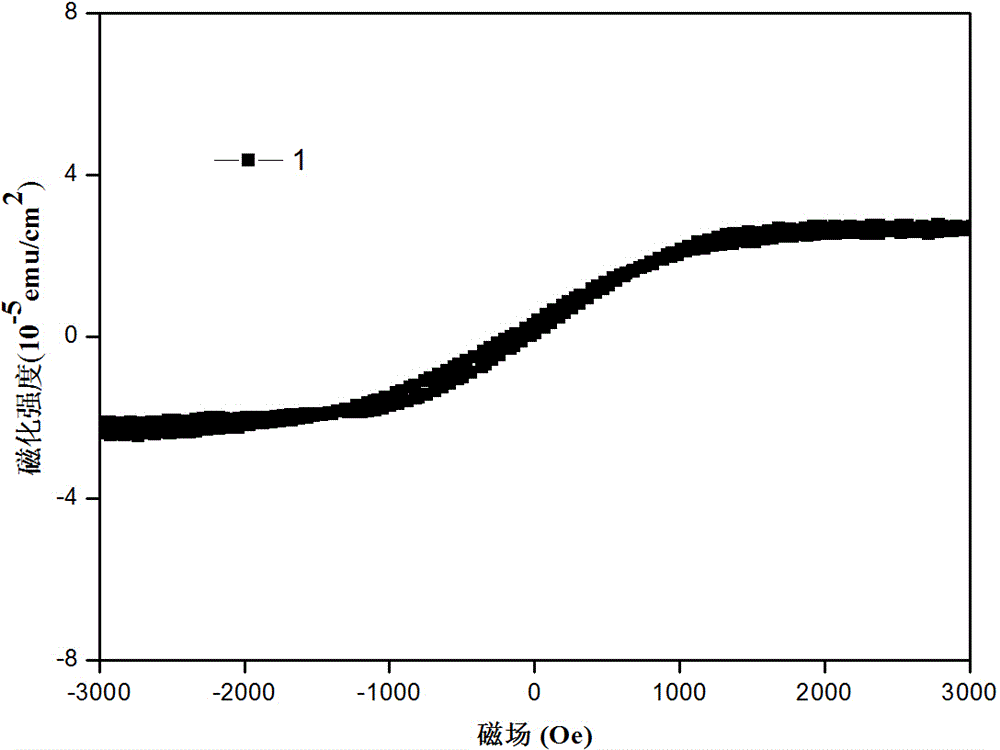

[0015] Rare earth element Sm doped GaN nanowires were prepared. The system used consists of a horizontal tube furnace heated by silicon-molybdenum rods, a gas system and a vacuum system. Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, and high-purity Sm 2 o 3 The powder was used as the Sm source. Weigh 0.3 g of Ga 2 o 3 . Place it in the middle of the horizontal tube furnace, and place the Si substrate 20-25 cm downstream of the central temperature zone to seal the horizontal tube furnace. Start the mechanical pump and molecular pump to evacuate the system, and evacuate the vacuum in the furnace to 1×10 -3 Pa, the purpose is to remove the residual water vapor and oxygen in the system. Ar gas was introduced, and the tube furnace was heated. The tube furnace was heated under the protection of Ar gas, and when the temperature reached 1100 °C, the Ar gas was replaced with 150 sccm NH 3 Air and keep warm for 2 h. Then the...

Embodiment 2

[0017] Rare earth element Sm doped GaN nanowires were prepared. The system used consists of a horizontal tube furnace heated by silicon-molybdenum rods, a gas system and a vacuum system. Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, and high-purity Sm 2 o 3 The powder was used as the Sm source. Weigh 0.3000 g of Ga 2 o 3 and 0.0296 g Sm 2 o 3 Powder, placed in an agate mortar and mixed thoroughly. Put the uniformly mixed powder into a ceramic boat, and place it in the middle of the horizontal tube furnace. At the same time, place a Si substrate at a position 20-20 cm downstream of the central temperature zone, and seal the horizontal tube furnace. furnace. Start the mechanical pump and molecular pump to evacuate the system, and evacuate the vacuum in the furnace to 1×10 -3 Pa, the purpose is to remove the residual water vapor and oxygen in the system. Ar gas was introduced, and the tube furnace was heated. The tub...

Embodiment 3

[0019] Rare earth element Sm doped GaN nanowires were prepared. The system used consists of a horizontal tube furnace heated by silicon-molybdenum rods, a gas system and a vacuum system. Using high-purity Ga 2 o 3 Powder and NH 3 Gas is used as Ga source and N source respectively, and high-purity Sm 2 o 3 The powder was used as the Sm source. Weigh 0.3000 g of Ga 2 o 3 and 0.0620 g Sm 2 o 3 Powder, placed in an agate mortar and mixed thoroughly. Put the uniformly mixed powder into a ceramic boat, and place it in the middle of the horizontal tube furnace. At the same time, place a Si substrate at a position 20-20 cm downstream of the central temperature zone, and seal the horizontal tube furnace. furnace. Start the mechanical pump and molecular pump to evacuate the system, and evacuate the vacuum in the furnace to 1×10 -3 Pa, the purpose is to remove the residual water vapor and oxygen in the system. Ar gas was introduced, and the tube furnace was heated. The tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com