Construction method for pressure pouring of concrete for tunnel secondary lining

A technology of pouring concrete and secondary lining, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc. It can solve the problems that the lining method of construction trolleys cannot be adopted, there are many joints in the lining blocks, and the waterproof effect is poor, so as to achieve good waterproof effect, Good engineering effect and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A tunnel secondary lining pressure pouring concrete construction method, comprising the following steps:

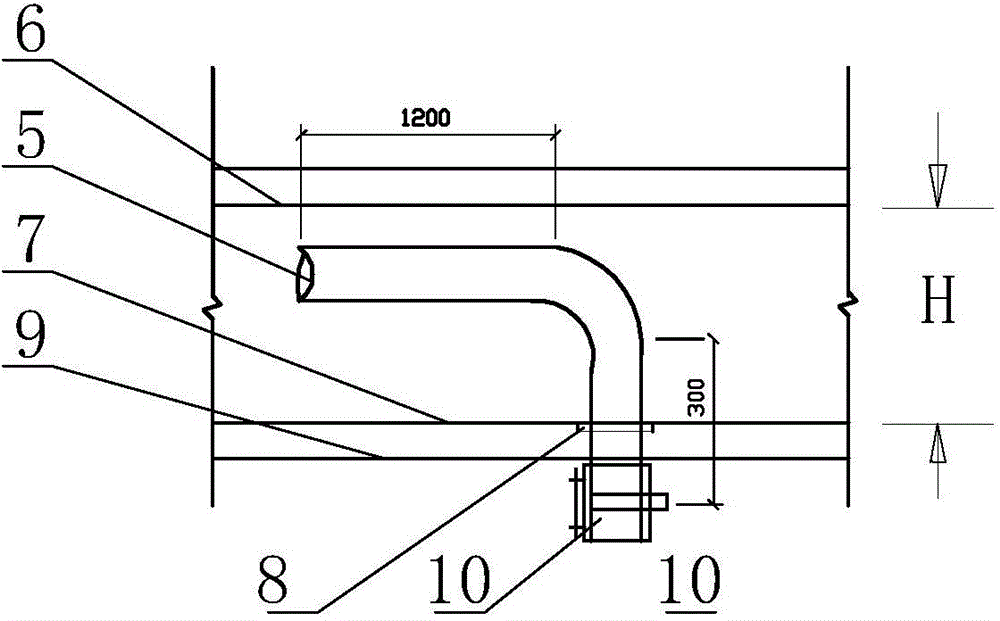

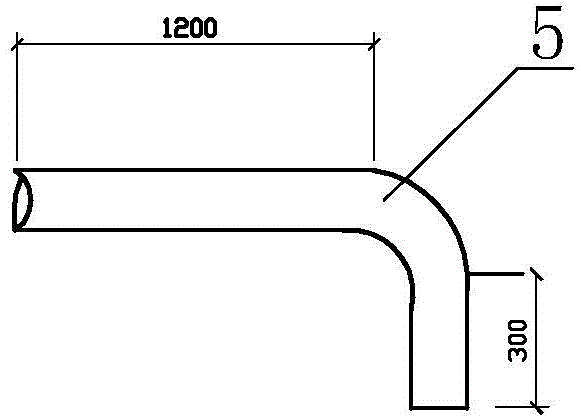

[0033] (1) Pre-embedded right-angled pump pipe: welded by Φ140 steel pipe and a 90° elbow, or directly bent Φ140 steel pipe to 90°, the length of one side of the right angle is 0.35m, and the length of the other side of the right angle is 1.2m;

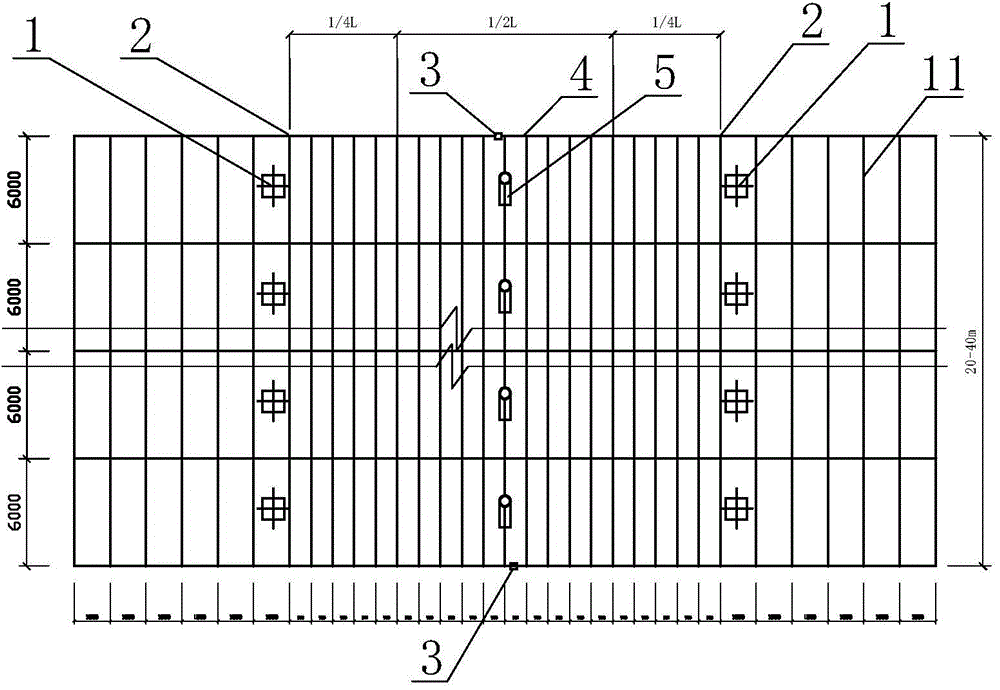

[0034] (2) Installing reinforcement frames: erecting reinforcement frames on the side walls and vaults of the tunnel. The length of each arch along the length of the tunnel is 20-40m, divided into inner and outer layers, and the distance between the inner and outer layers is the thickness of the concrete minus the thickness of the reinforcement and protective layer;

[0035] According to the design requirements, after deducting the thickness of the steel bars and the protective layer, the clear space distance between the inner and outer steel bars of the steel frame should be greater than the diameter of the embedded pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com