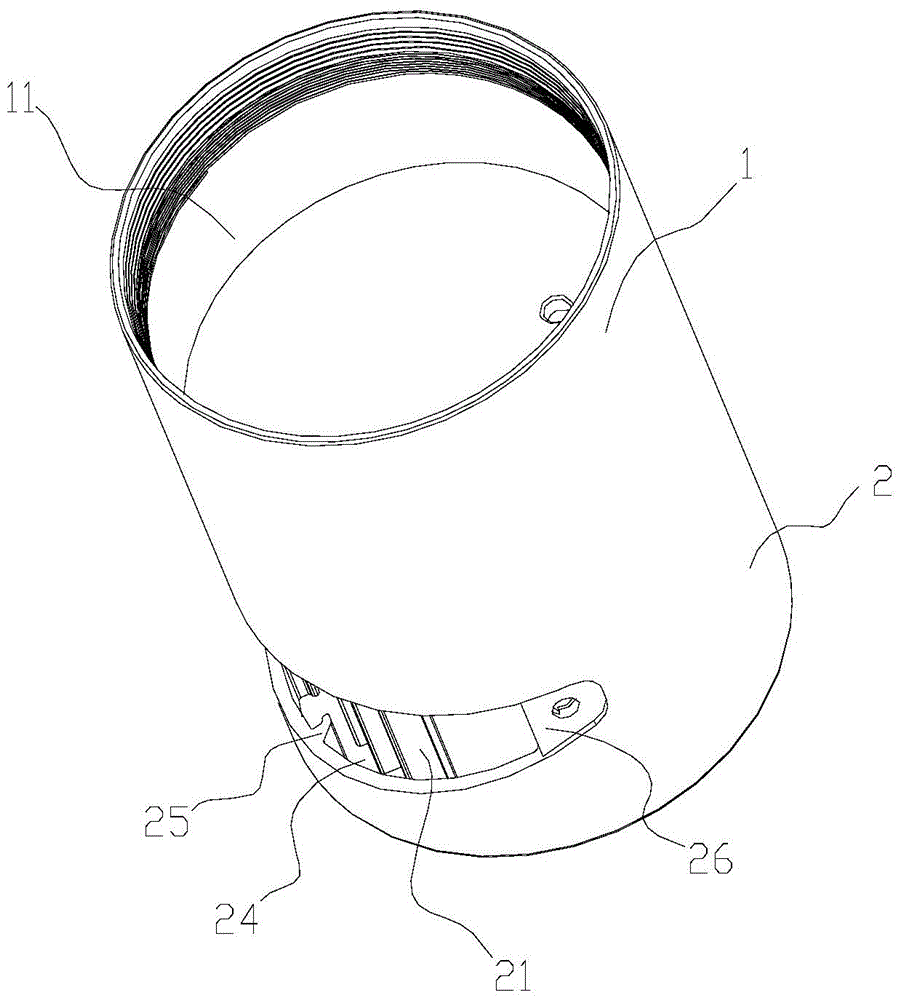

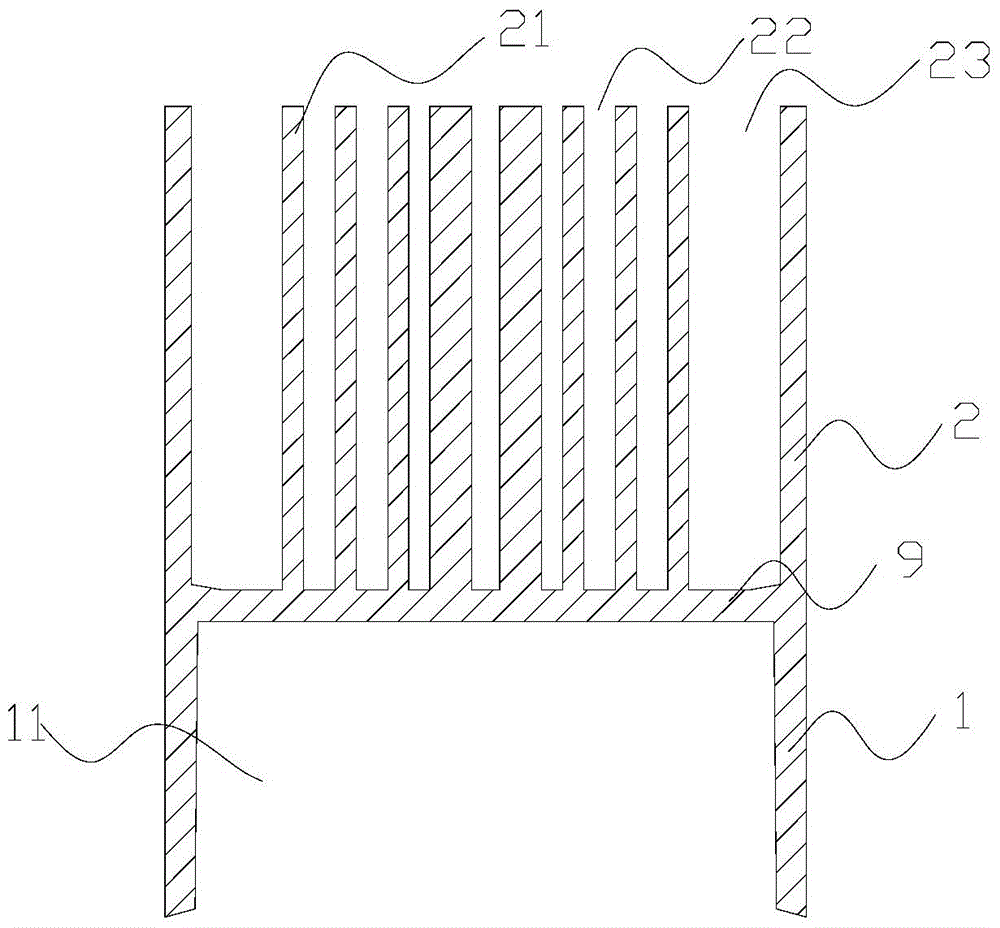

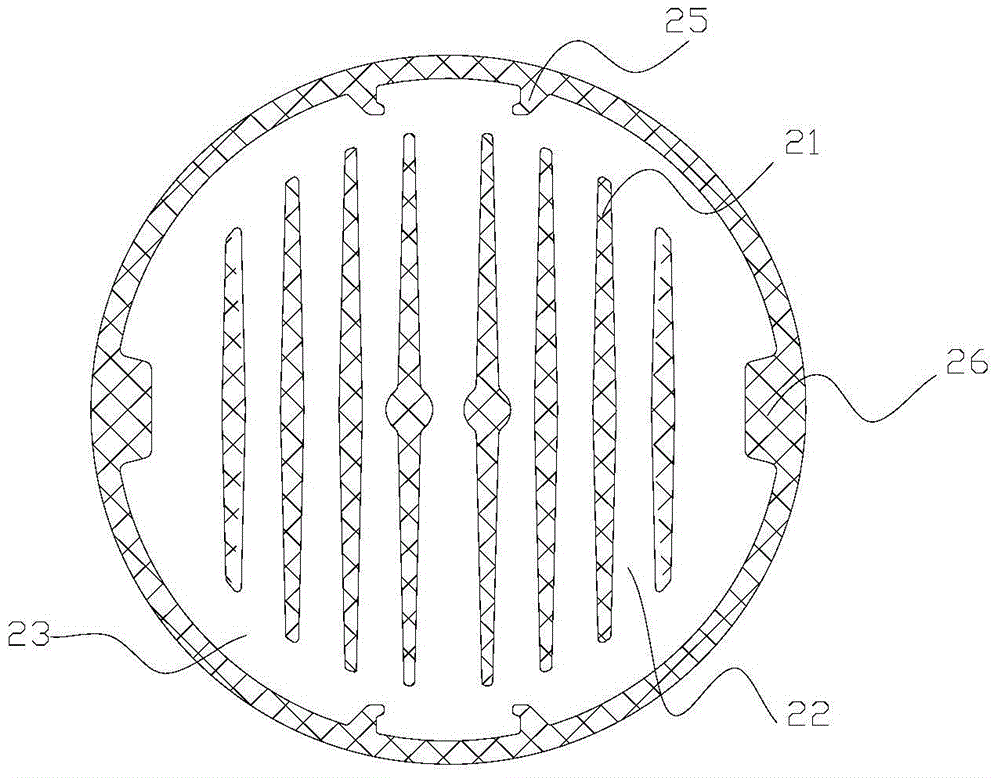

LED lamp housing, manufacturing method and manufacture die thereof

A technology of LED lamp housing and manufacturing method, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, and damage prevention measures for lighting devices, which can solve the problems of complex process and high processing cost, and achieve simple process and good heat dissipation effect , Improve the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare the aluminum cake: Calculate the material consumption of the aluminum cake according to the structure of the product blank, and use "material weight = product blank volume * material density * (1+ material loss ratio)" to estimate; in this embodiment, pure aluminum AL1070 is used is a material with a density of 2.7g / cm 3 , the loss ratio is 5-8%. Calculate the size of the aluminum cake according to the external dimensions of the product, wherein, the diameter of the aluminum cake = the outer diameter of the product + the machining allowance, and the thickness of the aluminum cake = the amount of material / the area of the bottom of the blank / the density of the material; According to the product blank structure, design the one-time molding blank structure;

[0047] 2) One-time forming blank: place the aluminum cake blank in the first accommodation cavity 51 of the first lower mold 5, lower the first punch 3, pressurize the aluminum cake blank by 368 tons, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com