Test system for intermediate frequency eddy current of carbon fiber resin matrix composite

A carbon fiber resin-based, eddy current detection technology, applied in the analysis of materials, material magnetic variables, material analysis through electromagnetic means, etc., can solve the problem of difficult design of high-frequency eddy current coils and signal processing and amplification circuits, and the signal is susceptible to external interference and The impact of coil lift-off, the difficulty of implementing high-frequency eddy current detection systems, etc., achieve the effect of low price, high sensitivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The following examples are carried out on the premise of the technical solution of the present invention, and specific implementation schemes and operation processes are provided, but the protection scope of the present invention is not limited to the following examples.

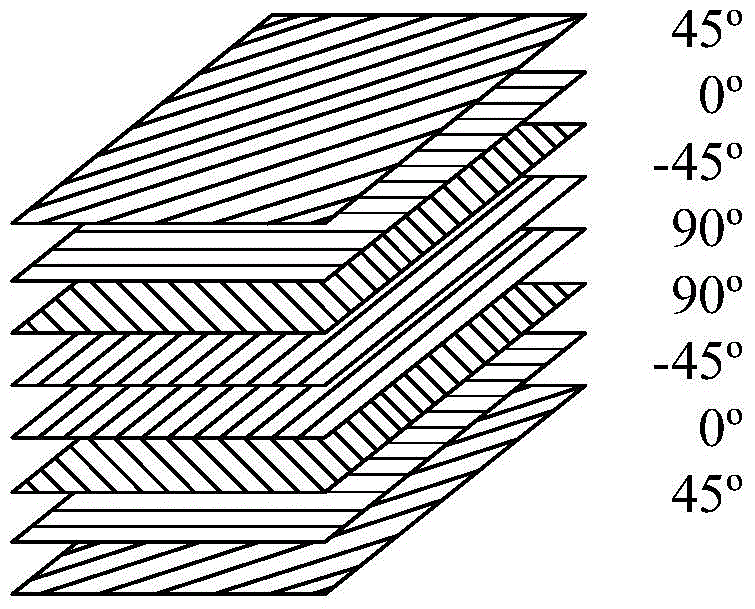

[0026] Such as figure 1 As shown, it is the sample to be tested in this embodiment—a CFRP composite material plate. The composite material is composed of fiber layers stacked in different angle directions, each layer is 0.125mm, and there are 8 layers in total. figure 1 One of the layup methods is shown.

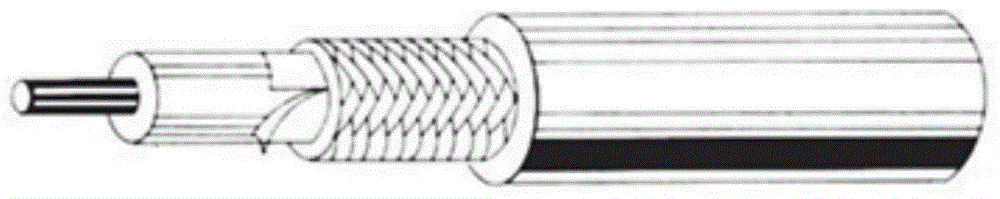

[0027] Such as figure 2 As shown, the transmission cable 4 used in this embodiment is composed of an inner conductor, an insulating layer, an aluminum foil shield, a braided shield and a sheath, and its length is less than 1m, and the parasitic capacitance valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com