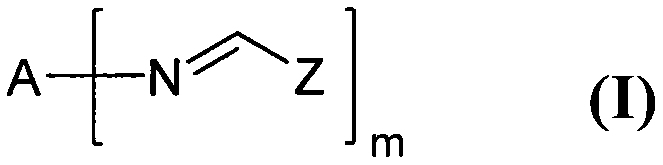

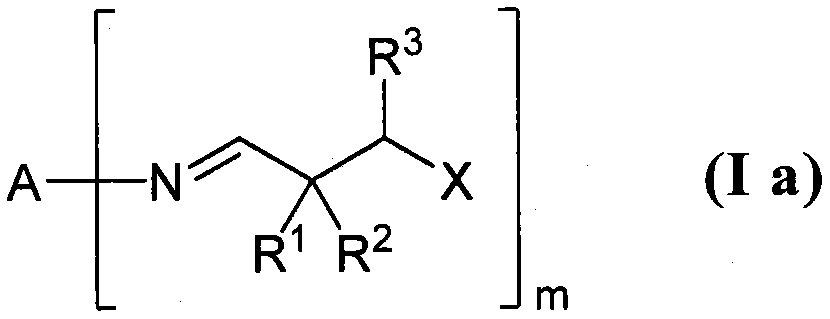

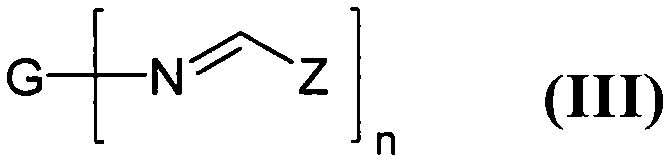

Liquid-applied waterproofing membrane for roofs comprising a long-chain aldimine

An aldimine and waterproof membrane technology, applied in the field of roofing applications, can solve the problems of unpleasant odor, difficult shelf life stability, difficult processability, slow curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0267] "Standard climate" means a temperature of 23 ± 1° C. and a relative atmospheric humidity of 50 ± 5%.

[0268] 1. Preparation of aldimine:

[0269] The amine content (total content of free and blocked amines, aldimino groups) of the prepared aldimines was determined by titration (0.1 N HClO in glacial acetic acid 4 , with crystal violet as indicator) and are given in mmol N / g.

[0270] Aldimine-A1: N,N'-bis(2,2-dimethyl-3-(N-morpholino)-propylene)-polyoxypropylenediamine

[0271] Under a nitrogen atmosphere, 2000g (about 2mol N) of polyoxypropylene diamine (about 2mol N) with an average molecular weight of about 2000g / mol D-2000, ex Huntsman, amine content 1.02 mmol N / g) was placed in a round bottom flask. Then 360 g (2.1 mol) of 2,2-dimethyl-3-(N-morpholino)-propanal were added with good stirring, and the volatile contents were then removed at 80° C. and 10 mbar vacuum. The yield was 2318 g of an almost colorless liquid with an amine content of 1.77 mmol N / g, corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com