Plant-based semi-interpenetrating network haemostatic dressing and preparation method thereof

The technology of semi-interpenetrating network and hemostatic dressing is applied in the field of semi-1 type interpenetrating network structure medical hemostatic dressing. , good biocompatibility, the effect of improving the liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

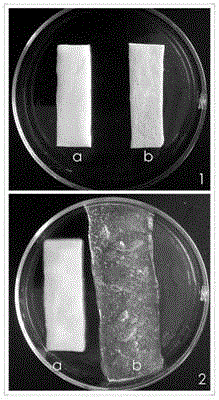

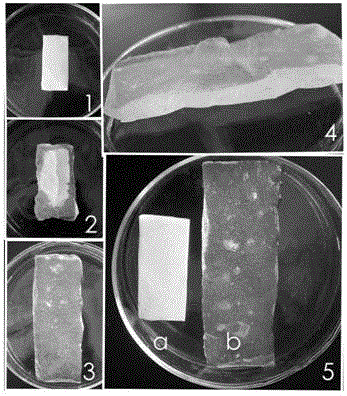

[0023] Example 1 Preparation of plant-based sponge dressing

[0024] Accurately weigh 5.0g of cornstarch, put it into a 50ml beaker, add 30ml of twice distilled water (w / v, the starch to water ratio is 1g / 6ml), put it in a water bath at 80°C, and mechanically stir it for 30min to dissolve and fully gelatinize it. Set to defoam, called A solution. After casting, it was vacuum-dried at room temperature for 2 hours to form a film, which is called A film. After He plasma treatment, the He flow rate was controlled to be 510L / min, the distance between the film and the electrode was 8mm, the processing power was 60W, and the discharge frequency was 10kHz. After being treated with He plasma for 10 min, the A film was exposed to the air for 15 min, and then put into a 5% F68 aqueous solution. The grafting reaction was carried out in an ice-water bath at 4°C under nitrogen and oxygen exhaust conditions. The grafted A film was called cornstarch-F68 film, and was washed with flowing dist...

Embodiment 2

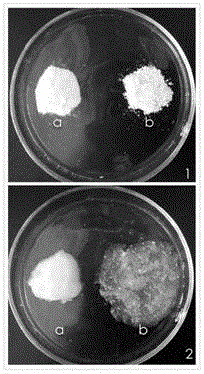

[0028] Example 2 Preparation of Plant-Based Powdered Dressing

[0029]Accurately weigh 10.0 g of pregelatinized potato starch, put it into a 50 ml beaker, stir it magnetically for 10 min to fully dissolve it, and call it A liquid. After casting, it was vacuum-dried at room temperature for 2 hours to form a film, called A film, treated with Ar plasma, the Ar flow rate was controlled at 500L / min, the distance between the film and the electrode was 7mm, the processing power was 60W, and the discharge frequency was 10kHz. After being treated with Ar plasma for 15 minutes, the A film was exposed to the air for 15 minutes, and then put into a solution containing 10% by mass of P338. The graft polymerization was carried out in an ice-water bath at 4°C under nitrogen and oxygen exhaust conditions. The grafted A film was called pregelatinized potato starch-P338 film. Rinse with flowing distilled water for 24h to remove unreacted P338 and the resulting copolymer. The obtained pregelat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com