Crude oil blending three-tank circulation process and its equipment

A crude oil and blending technology, applied in the field of blending process, can solve the problems of increased time and power consumption cost, increased crude oil emulsification, increased difficulty in dehydration, etc., to achieve the effects of increased equipment fluctuation, sufficient dehydration time, and avoidance of re-layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

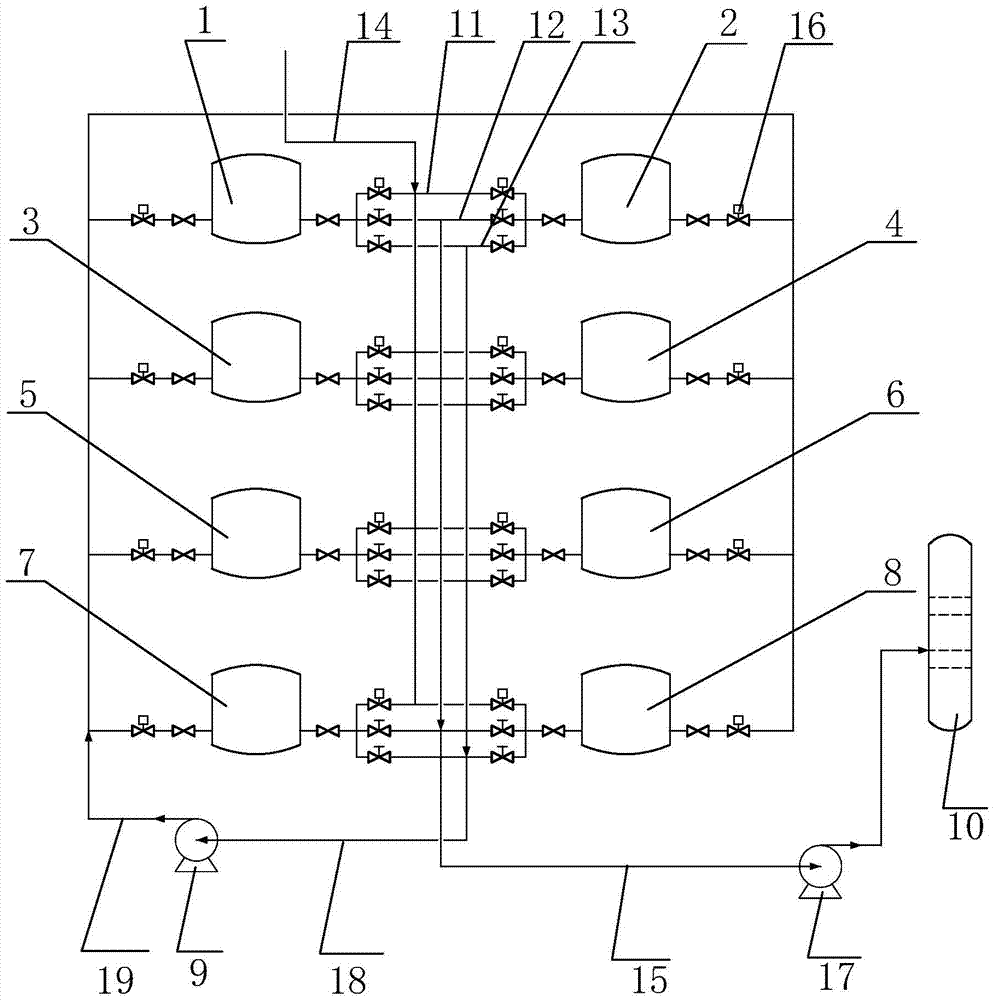

[0036] exist figure 1 Among them, 3 target tanks: No. 1 target tank 1, No. 2 target tank 2, No. 3 target tank 3 are used for crude oil blending, 5 crude oil tanks: No. 1 crude oil tank 4, No. 2 crude oil tank 5, 3 Crude oil tank No. 6, No. 4 crude oil tank 7, and No. 5 crude oil tank 8 respectively store Dal Oil, Saudi Arabian Oil, Oman Oil, Iranian Light Oil and Saudi Light Oil, and their densities are: 890.0, 868.4, 866.8, 857.4 and 854.6kg / m 3 (20°C). The blending order, blending ratio and liquid level drop value of the five crude oils are as follows:

[0037] harmonic order 1 2 3 4 5 Crude Oil Varieties Dahl oil oil in sand Oman oil Iranian light oil Sand Light Oil Harmony ratio, wt 5.6% 20.2% 43.8% 3.4% 27.0% Tank tag No. 1 crude oil tank No. 2 crude oil tank No. 3 crude oil tank No. 4 crude oil tank No. 5 crude oil tank Liquid level drop value, m 0.86 2.05 6.93 0.54 2.78

[0038] The total blending v...

Embodiment 2

[0048] exist figure 1 Among them, 3 target tanks: No. 1 target tank 1, No. 2 target tank 2, No. 3 target tank 3 are used for crude oil blending, 5 crude oil tanks: No. 1 crude oil tank 4, No. 2 crude oil tank 5, 3 Crude oil tank No. 6, No. 4 crude oil tank 7, and No. 5 crude oil tank 8 respectively store Dal Oil, Sand Oil, Oman Oil, Sand Light Oil and Upper Zakum Oil, and their densities are: 890.0, 868.4, 866.8, 854.6 and 850.9kg / m 3 (20°C). The blending order, blending ratio and liquid level drop value of the five crude oils are as follows:

[0049] harmonic order 1 2 3 4 5 Crude Oil Varieties Dahl oil oil in sand Oman oil Sand Light Oil Upper Zakum Oil Harmony ratio, wt 5.6% 15.7% 46.1% 20.2% 12.4% Tank tag No. 1 crude oil tank No. 2 crude oil tank No. 3 crude oil tank No. 4 crude oil tank No. 5 crude oil tank Liquid level drop value, m 0.86 1.60 4.68 2.08 1.99

[0050] The total blending volume is 69,4...

Embodiment 3

[0060] exist figure 1 Among them, 3 target tanks: No. 1 target tank 1, No. 2 target tank 2, No. 3 target tank 3 are used for crude oil blending, 5 crude oil tanks: No. 1 crude oil tank 4, No. 2 crude oil tank 5, 3 Crude oil tank No. 6, No. 4 crude oil tank 7, and No. 5 crude oil tank 8 store Perinis, cocoa butter, Nile oil, Cabinda oil and Sahara oil respectively, and their densities are: 923.0, 872.5, 872.0 , 866.0 and 812.0kg / m 3 (20°C). The blending order, blending ratio and liquid level drop value of the five crude oils are as follows:

[0061] harmonic order 1 2 3 4 5 Crude Oil Varieties Pyrene oil cocoa butter nile oil cabinda oil sahara oil Harmony ratio, wt 18.0% 14.6% 12.4% 21.3% 33.7% Tank tag No. 1 crude oil tank No. 2 crude oil tank No. 3 crude oil tank No. 4 crude oil tank No. 5 crude oil tank Liquid level drop value, m 2.68 2.28 1.94 2.17 4.78

[0062] The total blending volume is 69,420 tons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com