Transfer decoration film

A decorative film and transfer-type technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of coating elasticity reduction, denaturation, stickiness, etc., to improve the durability of use and the sense of touch Feel soft and comfortable, maintain the effect of soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

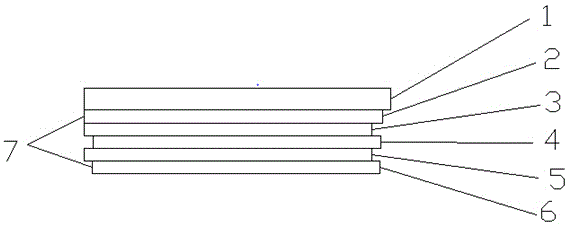

[0073] A PET carrier film with a thickness of 70 μm is used, and a release layer with a thickness of 0.5 μm, a tactile functional layer with a thickness of 30 μm, and a colored layer with a thickness of 0.5 μm are sequentially coated on one side of the carrier film.

[0074] ①The components and parts by weight in the release layer are as follows:

[0075]

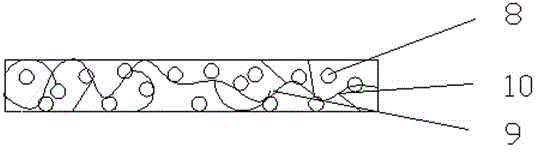

[0076] ②The tactile functional layer adopts UV curing system, and the components and their parts by weight are as follows:

[0077]

[0078]

[0079] ③The components of the coloring layer and their parts by weight are as follows

[0080]

[0081] ④A vacuum evaporation process is adopted on the colored layer to evaporate an aluminum layer with a thickness of 40nm.

[0082] ⑤The adhesive layer is configured as a coating solution according to the conventional method, and coated on the aluminum-coated layer;

[0083] The decorative film prepared according to the above scheme was applied and processed, and the perf...

Embodiment 2

[0085] A PET carrier film with a thickness of 50 μm is used, and a release layer with a thickness of 0.8 μm, a tactile functional layer with a thickness of 25 μm, and a colored layer with a thickness of 0.8 μm are sequentially coated on one side of the carrier film.

[0086] ①The components and parts by weight in the release layer are as follows:

[0087]

[0088] ②The tactile functional layer adopts UV curing system, and the components and their parts by weight are as follows:

[0089]

[0090] ③The components and parts by weight of the coloring layer are as follows:

[0091]

[0092] ④A vacuum evaporation process is adopted on the coloring layer to evaporate a silver layer with a thickness of 45nm.

[0093] ⑤ The adhesive layer is configured as a coating solution according to the conventional method, and coated on the silver-plated layer;

[0094] The decorative film prepared according to the above scheme was applied and processed, and the performance test was car...

Embodiment 3

[0096] A PET carrier film with a thickness of 35 μm is used, and a release layer with a thickness of 1.0 μm, a tactile functional layer with a thickness of 20 μm, and a colored layer with a thickness of 0.5 μm are sequentially coated on one side of the carrier film.

[0097] ①The components and parts by weight in the release layer are as follows:

[0098]

[0099]

[0100] ②The tactile functional layer adopts UV curing system, and the components and their parts by weight are as follows:

[0101]

[0102] ③The components of the coloring layer and their parts by weight are as follows

[0103]

[0104] ④A vacuum evaporation process is adopted on the coloring layer to evaporate a copper layer with a thickness of 30nm.

[0105] ⑤ The adhesive layer is configured as a coating solution according to the conventional method, and coated on the copper plating layer;

[0106] The decorative film prepared according to the above scheme was applied and processed, and the performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com