Early-strength bracket grouting material and preparation method thereof

A grouting material and bearing technology, which is applied in the field of engineering materials, can solve the problems of slow strength development, affecting construction progress, and lack of close connection of bearings, and achieves the effect of smooth surface, good construction performance, and long operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

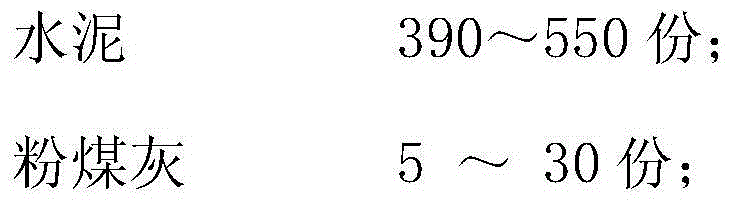

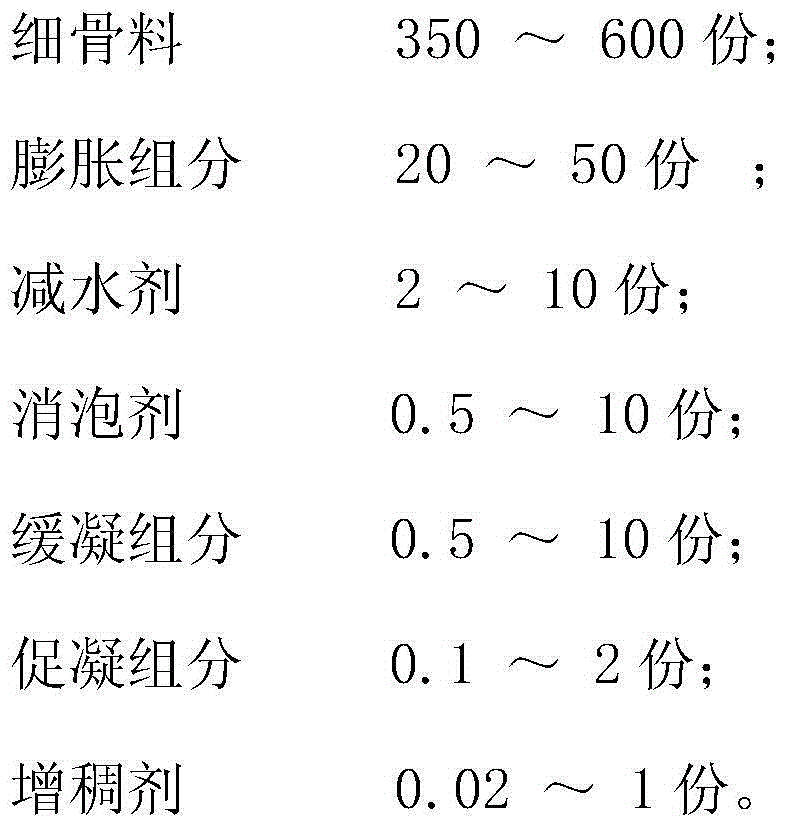

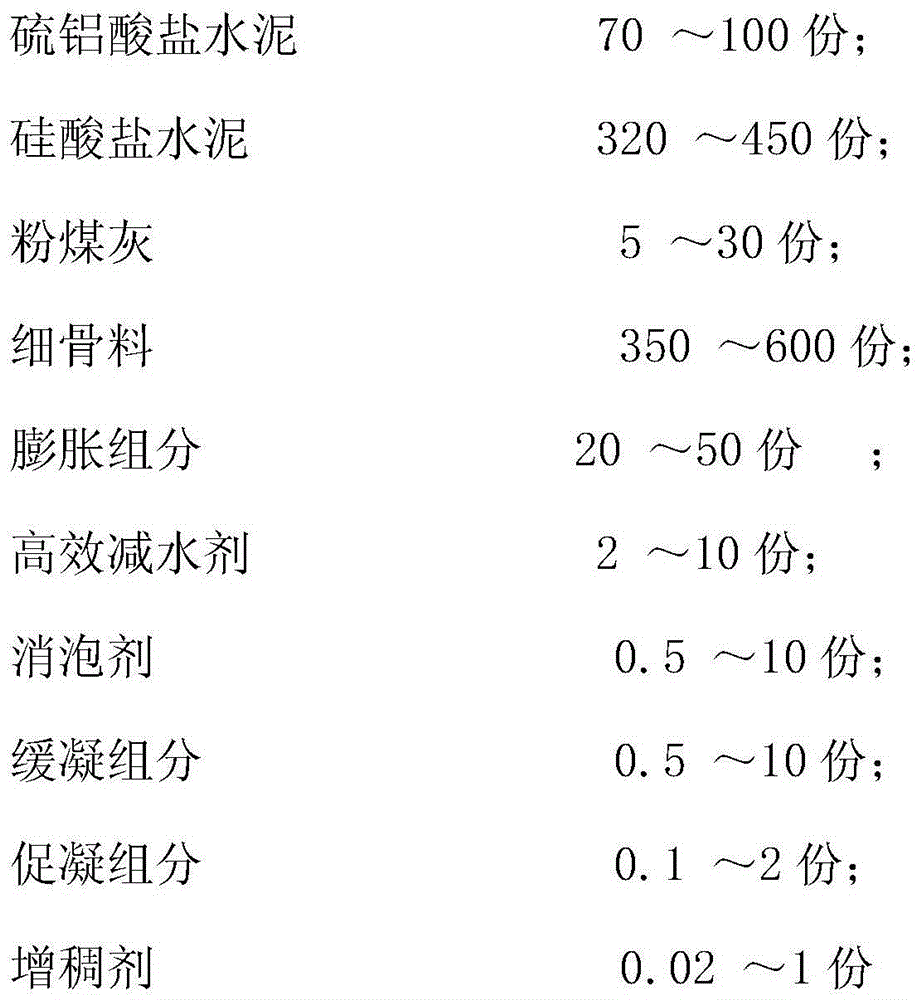

[0017] An early-strength bearing grouting material, comprising the following components in parts by weight:

[0018]

[0019] Wherein, the expansion component in this embodiment can choose UEA expansion agent or / and CSA expansion agent. The thickener can be selected from one or more of hydroxymethyl cellulose, hydroxyethyl cellulose, hydroxypropyl methyl cellulose and bentonite.

[0020] When in use, the material is directly stirred with water, and the weight ratio of water to material is 0.12-0.14. The early-strength bearing grouting material has good fluidity, durability, filling, early-strength, high-strength, micro-expansion and suitable setting time.

[0021] The material has good construction performance, self-levelling, long operating time, and smooth surface after pouring, which overcomes the shortcomings of traditional mortar such as unevenness, easy cracking, peeling, and powdering. It is often used in bridge supports and large-scale equipment. Secondary groutin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com