Heat storage wall material

A wall material and heat storage technology, applied in the field of construction, can solve the problems of poor thermal insulation effect of materials, many building materials such as cement, and low compressive strength, and achieve good compressive strength, low production cost, and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

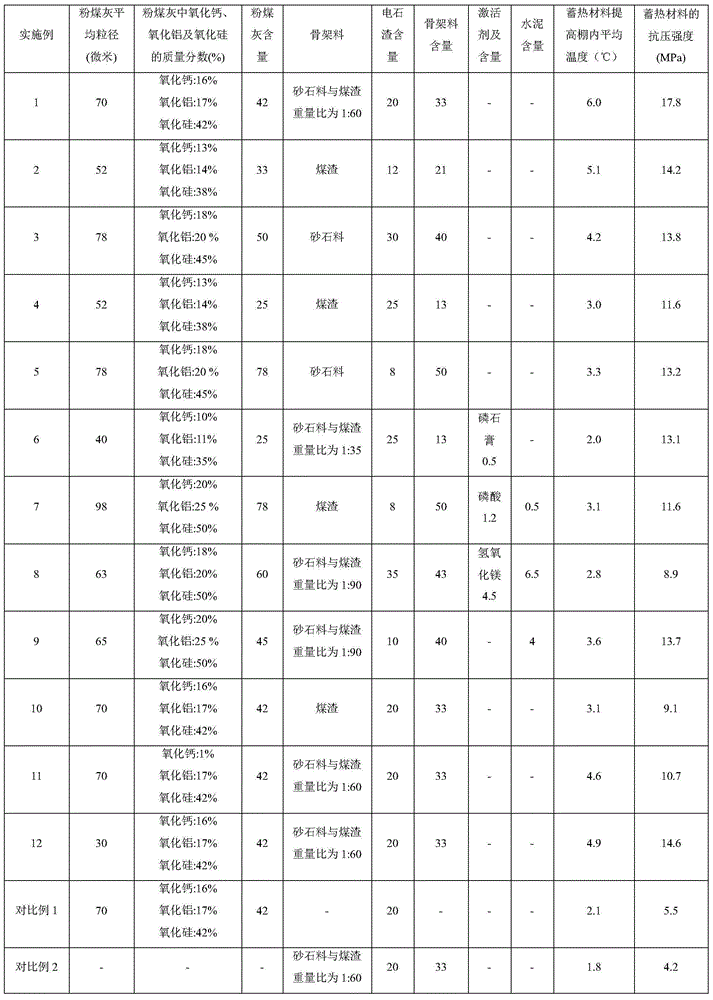

Examples

preparation example Construction

[0023] According to the present invention, the preparation method of the thermal storage wall material may include: mixing water, fly ash, calcium carbide slag and skeleton material and stirring evenly, or adding a certain amount of activator and / or cement at the same time and stirring evenly, and then the Thermal storage wall materials. For example, water, fly ash, calcium carbide slag and skeleton materials can be mixed and stirred evenly, and then bricks can be tamped into bricks by hand pouring or pressed by a pressing machine to make bricks or required walls; for example, Water, fly ash, calcium carbide slag, skeleton material, activator and / or cement can be mixed evenly, and then bricks can be tamped into bricks by hand pouring or pressed by a pressing machine to make bricks or required walls.

[0024] A preferred embodiment of the present invention is as follows: firstly mix fly ash, calcium carbide slag and water fully, then add a certain amount of framework material a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com