Water-based glaze and preparation method thereof

A water-based, water-added technology, applied in coatings and other directions, can solve the problems of needing 5-10 years to completely volatilize and clean, the atmosphere is polluted, and the human body is harmful, and achieves the effect of strong antique effect, added value and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

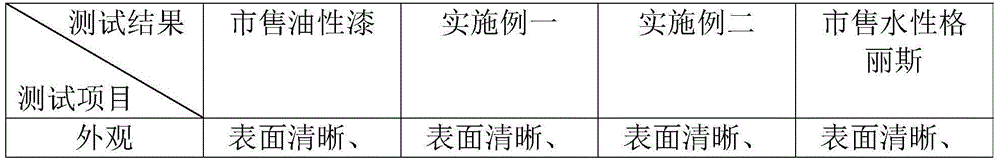

Examples

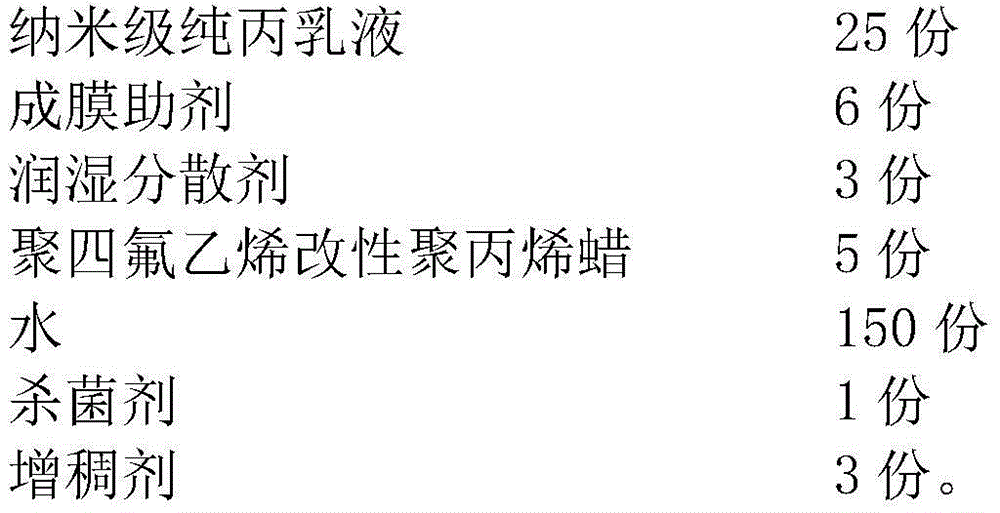

Embodiment 1

[0027] A kind of water-based Gris, comprising the following components in parts by weight: 25 parts of nano-scale pure acrylic emulsion, 6 parts of DPNB, 3 parts of wetting and dispersing agent, 5 parts of polytetrafluoroethylene modified polypropylene wax, 150 parts of water 1 part, 1 part of fungicide, 3 parts of thickener.

[0028] The preparation method of above-mentioned Water Grace, comprises the steps:

[0029] (1) Put 25 parts of nano-scale pure acrylic emulsion into the container;

[0030] (2) First mix 10 parts of water with 6 parts of DPNB, then slowly put it into the container, stir at a medium speed of 500-800r / min for 5min until uniform;

[0031] (3) Slowly add 3 parts of wetting and dispersing agent under stirring at a medium speed of 500-800r / min, and stir for 5 minutes until uniform;

[0032] (4) After slowly putting 5 parts of polytetrafluoroethylene modified polypropylene wax into the container, stir and disperse at a high speed of 1000-1200r / min for 18min...

Embodiment 2

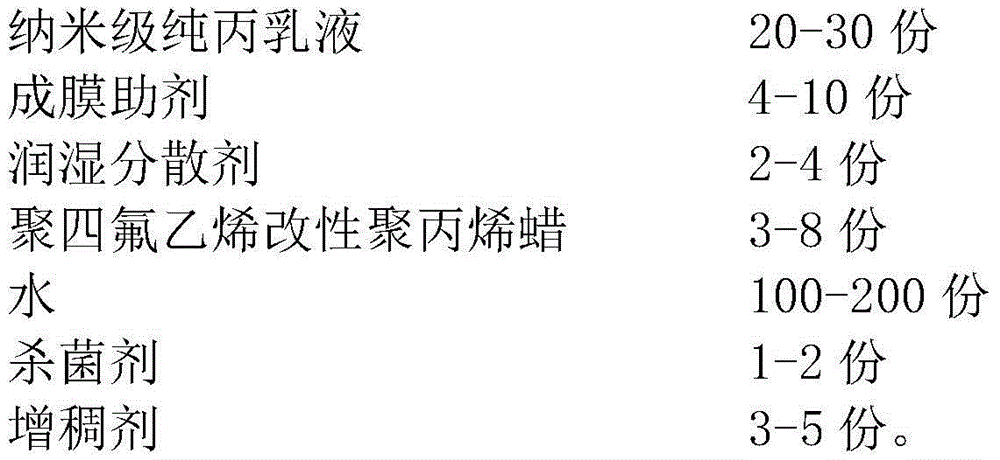

[0035] A kind of water-based Gris, comprising the following components in parts by weight: 20 parts of nano-scale pure acrylic emulsion, 4 parts of DPNB, 2 parts of wetting and dispersing agent, 3 parts of polytetrafluoroethylene modified polypropylene wax, 100 parts of water 1 part, 1 part of fungicide, 3 parts of thickener.

[0036] The preparation method of above-mentioned Water Grace, comprises the steps:

[0037] (1) Put 20 parts of nano-scale pure acrylic emulsion into the container;

[0038] (2) First mix 10 parts of water with 4 parts of DPNB, then slowly put it into the container, stir at a medium speed of 500-800r / min for 5 minutes until uniform;

[0039] (3) Slowly add 2 parts of wetting and dispersing agent under stirring at a medium speed of 500-800r / min, and stir for 5 minutes until uniform;

[0040] (4) After slowly putting 3 parts of polytetrafluoroethylene modified polypropylene wax into the container, stir and disperse at a high speed of 1000-1200r / min for ...

Embodiment 3

[0043] A kind of water-based Gris, comprising the following components in parts by weight: 30 parts of nano-scale pure acrylic emulsion, 10 parts of DPNB, 4 parts of wetting and dispersing agent, 8 parts of polytetrafluoroethylene modified polypropylene wax, 200 parts of water 1 part, 1 part of fungicide, 3 parts of thickener.

[0044] The preparation method of above-mentioned Water Grace, comprises the steps:

[0045] (1) Put 30 parts of nano-scale pure acrylic emulsion into the container;

[0046] (2) First mix 10 parts of water with 10 parts of DPNB, then slowly put it into the container, stir at a medium speed of 500-800r / min for 5min until uniform;

[0047] (3) Slowly add 4 parts of wetting and dispersing agent under stirring at a medium speed of 500-800r / min, and stir for 5 minutes until uniform;

[0048] (4) After slowly putting 8 parts of polytetrafluoroethylene modified polypropylene wax into the container, stir and disperse at a high speed of 1000-1200r / min for 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com