Biodiesel preparation device and method for preparing biodiesel using same

A technology of biodiesel and preparation equipment, which is applied in the field of oleochemical industry, can solve the problems of low conversion rate of the preparation process, and achieve the effects of high purity, excellent method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

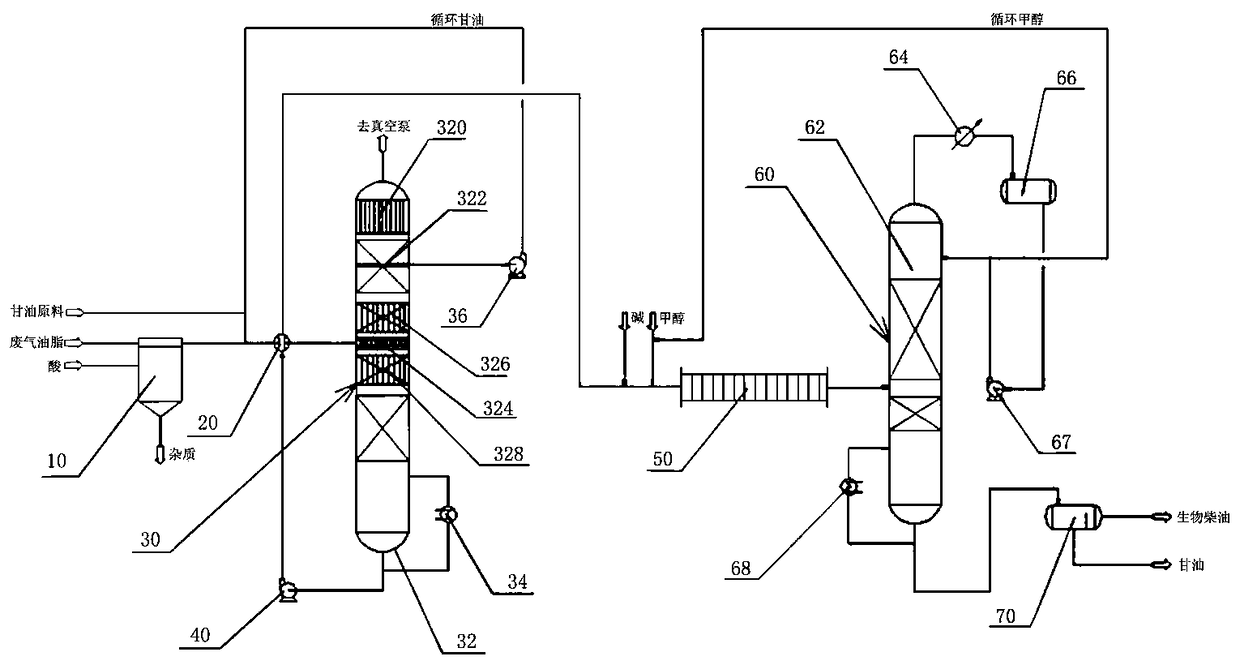

preparation example Construction

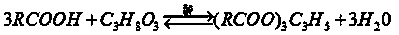

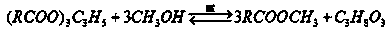

[0064] The above-mentioned biodiesel preparation device is excellent, and the waste oil or acidified oil is mixed with glycerin after being pretreated by the preprocessor 10, so as to avoid the impact of impurities on the catalyst activity of the subsequent esterification reaction and transesterification reaction. The esterification reaction tower 30 is used, The impurity-removing raw materials and glycerin have a long enough residence time in the catalytic reaction section, water and esterification products are removed quickly, the conversion rate is improved, and the purity of the esterification products is high, so that the subsequent transesterification reaction uses less catalyst. The reaction can be carried out, and the yield of biodiesel is relatively high. Glycerol and methanol are recycled so that the reaction can be carried out continuously.

[0065] A kind of method utilizing above-mentioned device to prepare biodiesel, comprises the following steps:

[0066] S110....

Embodiment 1

[0092] After the waste oil enters the preprocessor to remove impurities, the impurity-removing raw material is obtained (the impurity-removing raw material contains 39.2wt% fatty acid glyceride, 2.4wt% water and 58.4wt% fatty acid).

[0093] 2685kg / h of the impurity-removing raw material, 195kg / h of glycerin and 320kg / h of circulating glycerin (containing 0.9wt% fatty acid glycerides and 99.1wt% of glycerin in the circulating glycerin) are mixed and then preheated into the preheater to After 190°C, it enters the esterification reaction tower for reaction. Due to rectification, the light components containing water and glycerin rise, and the heavy components containing fatty acid glycerides decrease.

[0094] After the light component containing water and glycerin rises into the rectification section, due to rectification, water is extracted from the top of the esterification reaction tower, and glycerin is extracted by the extractor to obtain circulating glycerin through a circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com