Cu strengthened co-free secondary hardening ultra-high strength steel and preparation method

An ultra-high-strength steel, secondary hardening technology, applied in the field of alloy steel, can solve the problems of reducing the Co content, poor economy, and the price is vulnerable to the impact of the international situation, and achieves the saving of Co element content, high economy, and good heat treatment. crafted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

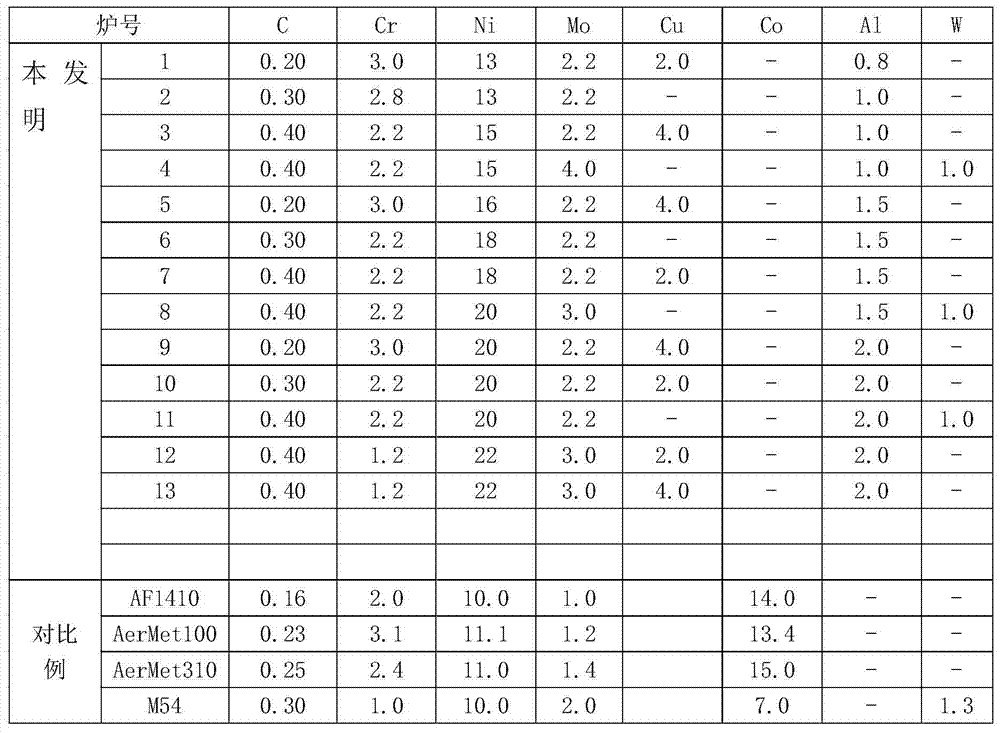

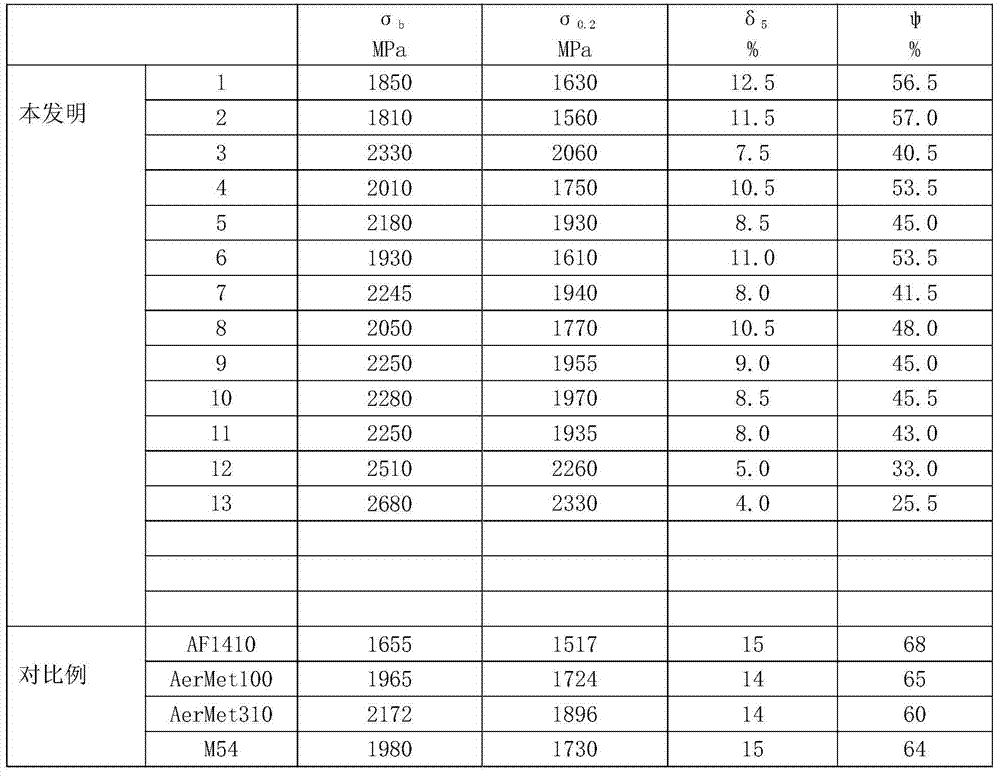

[0041] According to the chemical composition scope of steel of the present invention, adopt 25 kilograms of vacuum induction furnaces to prepare 21 kilograms of alloy ingots, its concrete chemical composition is shown in Table 3, and furnace number is 1 # ~13 # .

[0042] After 13 batches of steel were smelted and cast into steel ingots, the high-temperature homogenization treatment system was first carried out before forging: after holding at 1200°C for 10 hours, the temperature was lowered for forging, and the forging heating temperature was 1150°C. The dimensions of forged test rods are: φ15×2000mm, 15×15×2000mm and 25×45×L.

[0043] After forging, the test bar is firstly subjected to normalizing and annealing heat treatment: normalizing treatment at 1050°C×1h, air cooling, annealing treatment at 680°C×6h, and air cooling. Then send the sample section to process the tensile, impact and fracture toughness sample blanks. The final heat treatment is quenching, deep cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com