A kind of preparation method of carbon fiber precursor lignin/polylactic acid fiber

A polylactic acid fiber and lignin technology, which is applied in the chemical characteristics of fibers, conjugated synthetic polymer rayon, conjugated rayon, etc., can solve the problems of high production cost, environmental pollution, difficulty in solvent recovery, and the like, Achieve low production costs, broad market prospects, and solve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

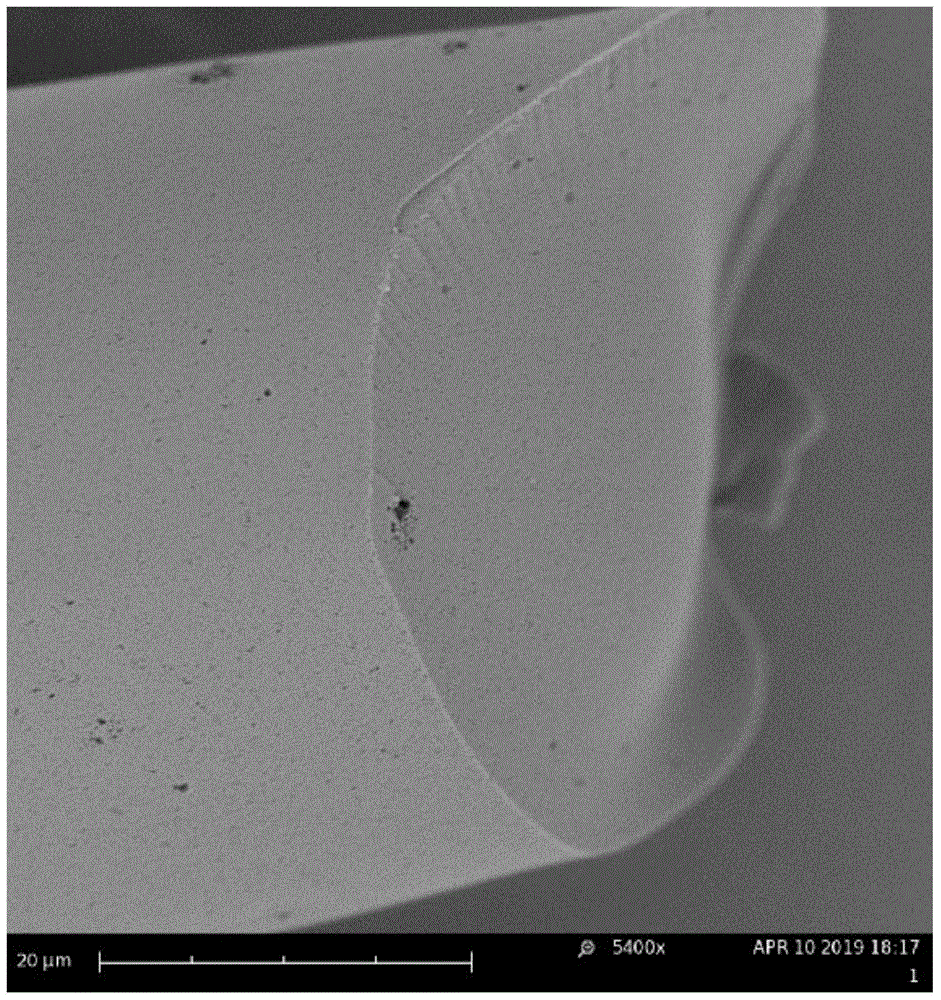

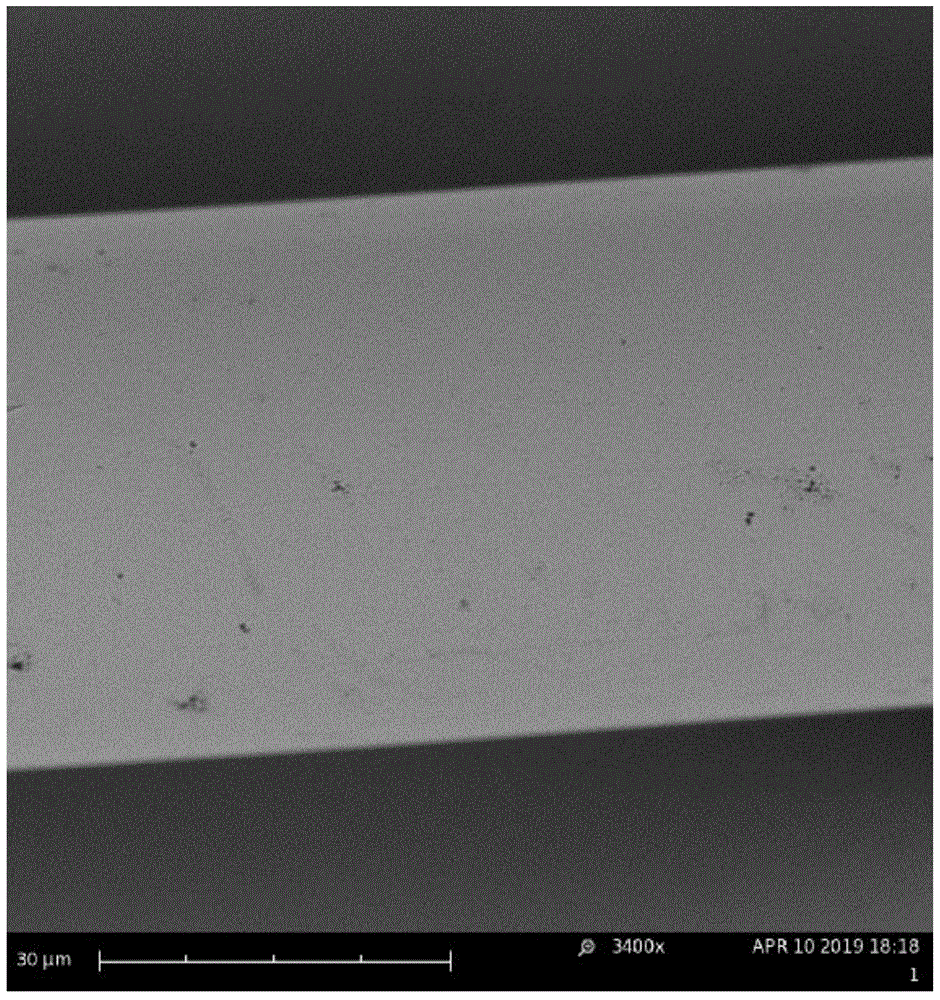

Embodiment 1

[0023] Slice lignin powder and polylactic acid (M w =1.77×10 5 , PDI=1.3) at 190° C. and 80° C. in a vacuum oven for intermittent heat treatment, and the heat treatment time was 0.5 h and 8 h, respectively. Fully mix 495g of heat-treated lignin powder and 5g of heat-treated polylactic acid slices, and obtain lignin / polylactic acid composite masterbatch through twin-screw granulation. °C and 225 °C. Put the dried composite masterbatch into a melt spinning machine for spinning to obtain lignin / polylactic acid composite fibers. The spinning temperature is 200-240°C, the speed of the metering pump is 20rpm, the specification is 1.8cc / r, and the spinneret The specification is 0.18mm×12f, the spinning speed is 100m / min, and the draft ratio is 1.1 times. The obtained lignin / polylactic acid composite fiber is pre-oxidized (the pre-oxidation temperature is 270°C, the heating rate is 0.1°C / min, and the pre-oxidation time is 10min) and carbonized (the carbonization temperature is 1000...

Embodiment 2

[0025] Slice lignin powder and polylactic acid (Mw=1.77×10 5 , PDI=1.3) at 200° C. and 90° C. in a vacuum oven for intermittent heat treatment, and the heat treatment time was 1 h and 6 h, respectively. Fully mix 475g of heat-treated lignin powder and 25g of heat-treated polylactic acid slices, and obtain lignin / polylactic acid composite masterbatch through twin-screw granulation. °C and 220 °C. Put the dried composite masterbatch into a melt spinning machine for spinning to obtain lignin / polylactic acid composite fibers. The spinning temperature is 200-240°C, the speed of the metering pump is 20rpm, the specification is 1.8cc / r, and the spinneret The specification is 0.18mm×12f, the spinning speed is 300m / min, and the draft ratio is 1.2 times. The obtained lignin / polylactic acid composite fiber is pre-oxidized (the pre-oxidation temperature is 280°C, the heating rate is 0.1°C / min, and the pre-oxidation time is 10min) and carbonized (the carbonization temperature is 1000°C, ...

Embodiment 3

[0027] Lignin powder and polylactic acid slices (Mw=1.77×105, PDI=1.3) were subjected to intermittent heat treatment in a vacuum oven at 210°C and 100°C for 2h and 10h, respectively. Fully mix 450g of heat-treated lignin powder and 50g of heat-treated polylactic acid slices, and obtain lignin / polylactic acid composite masterbatch through twin-screw granulation. °C and 215 °C. Put the dried composite masterbatch into a melt spinning machine for spinning to obtain lignin / polylactic acid composite fibers. The spinning temperature is 200-230°C, the speed of the metering pump is 30rpm, the specification is 1.8cc / r, and the spinneret The specification is 0.18mm×12f, the spinning speed is 500m / min, and the draft ratio is 1.3 times. The obtained lignin / polylactic acid composite fiber was preoxidized (the preoxidation temperature was 290°C, the heating rate was 0.2°C / min, and the preoxidation time was 10min) and carbonized (the carbonization temperature was 1000°C, and the heating rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com