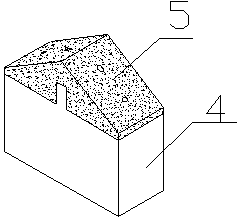

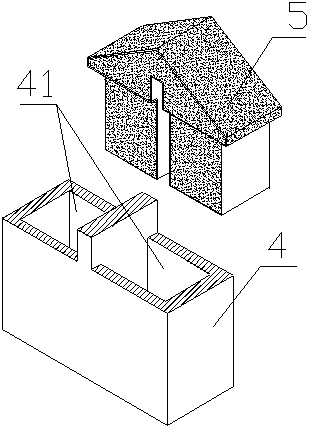

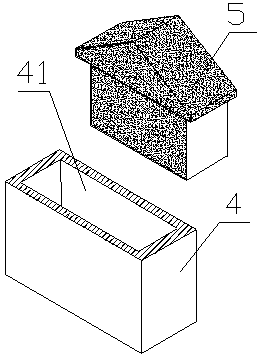

Novel structural sound-absorption brick, special mold and preparation method

A new structure and technology of sound-absorbing bricks, applied in the field of sound-absorbing bricks, can solve the problems of low compression resistance of the pressure-bearing part, traffic accidents of the sound-absorbing part, and inability to stack up to a higher level, so as to prevent mutual separation and high production efficiency. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing a sound-absorbing brick of the above-mentioned novel structure, which comprises the following steps:

[0057] 1) Raw material preparation, take the following raw materials in parts by weight:

[0058] Pressure-bearing part 4: Cement: 40

[0059] Yellow Sand: 50

[0060] Latex powder: 8

[0061] Superplasticizer: 2

[0062] Water: Appropriate amount

[0063] Acoustic part 5: Perlite: 30

[0064] Cement: 68

[0065] Hydrophobic agent: 1

[0066] Fiber: 1

[0067] Water: Appropriate amount

[0068] The cement model can be selected as ordinary portland cement, slag portland cement, etc.; the yellow sand is preferably washed and dried sand with a particle size of 40 mesh to 70 mesh; the latex powder is polyvinyl acetate, Acrylic, styrene-butadiene latex rubber powder com...

Embodiment 2

[0077] The preparation method of the sound-absorbing brick of the above-mentioned novel structure provided in this embodiment comprises the following steps:

[0078] 1) Raw material preparation, take the following raw materials by weight:

[0079] Pressure-bearing part 4: Cement: 30

[0080] Yellow sand: 60

[0081] Latex powder: 13

[0082] Water reducer: 1

[0083] Water: Appropriate amount

[0084] Acoustic part 5: Perlite: 40

[0085] Cement: 40

[0086] Hydrophobic agent: 0.5

[0087] Fiber: 3

[0088] Water: Appropriate amount

[0089] Raw material specifications and other steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0091] The preparation method of the sound-absorbing brick of the above-mentioned novel structure provided in this embodiment comprises the following steps:

[0092] 1) Raw material preparation, take the following raw materials by weight:

[0093] Pressure-bearing part 4: Cement: 50

[0094] Yellow sand: 40

[0095] Latex powder: 7

[0096] Superplasticizer: 3

[0097] Water: Appropriate amount

[0098] Acoustic part 5: Perlite: 20

[0099] Cement: 55

[0100] Hydrophobic agent: 3

[0101] Fiber: 1

[0102] Water: Appropriate amount

[0103] Raw material specifications and other steps are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com