Mixed refrigerant recovery and reinjection process and device

A technology for mixing refrigerants and refrigerants, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult refrigerant recovery, high energy consumption in the liquefaction process, and complicated operations, and improve the adaptability to changing conditions. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

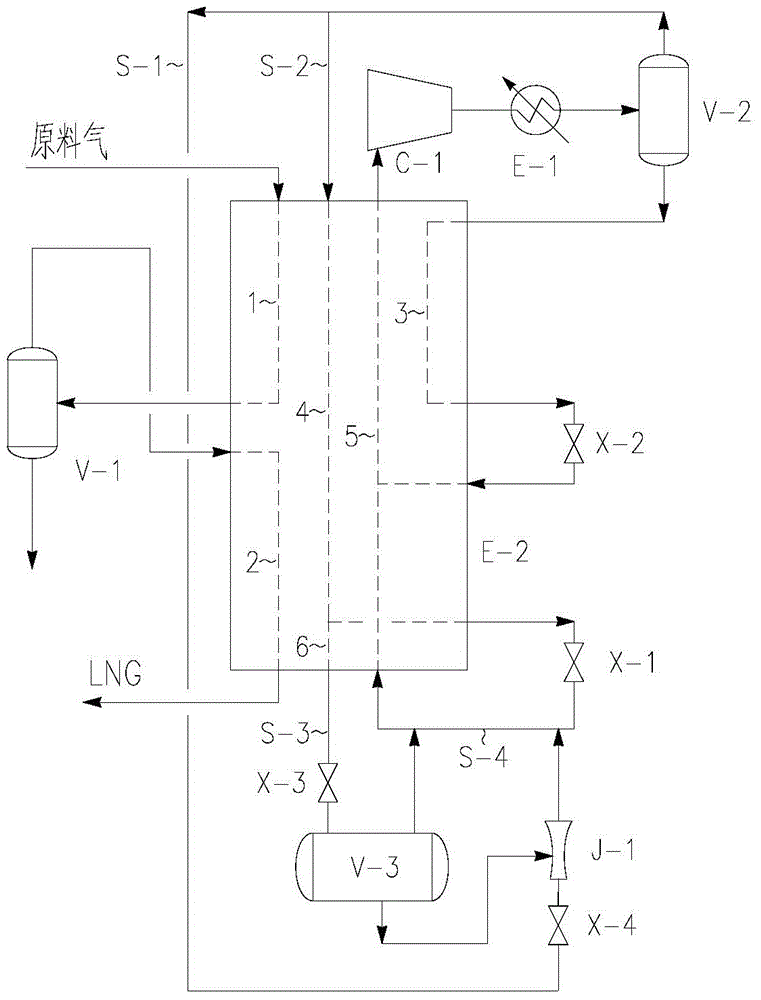

[0019] The invention provides a mixed refrigerant recovery process, which is suitable for recovering the mixed refrigerant in the refrigerant circulation system, that is, the cold box and the refrigerant compressor when the mixed refrigerant liquefaction device is shut down; the natural gas is liquefied in the cold box , the heat exchange component in the cold box is a plate-fin heat exchanger.

[0020] Further description below in conjunction with accompanying drawings.

[0021] When the liquefaction unit is in normal operation, its process includes natural gas liquefaction and mixed refrigerant cycle:

[0022] Natural gas liquefaction: The raw natural gas first enters the first channel 1 of the plate-fin heat exchanger for pre-cooling, and after being cooled to -30°C ~ -60°C, it enters the heavy hydrocarbon separator V-1 for gas-liquid separation. The liquid separated from the bottom of the separator V-1 is heavy hydrocarbons, and the gas phase stream separated from the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com