Spiral guide snow maker

A snow-making and spiral technology, which is applied in ice-making, lighting and heating equipment, recreational ice-making, etc., can solve the problems of high investment cost, high technical content, complex structure, etc., and achieve low investment cost, simple equipment structure and easy maintenance. The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

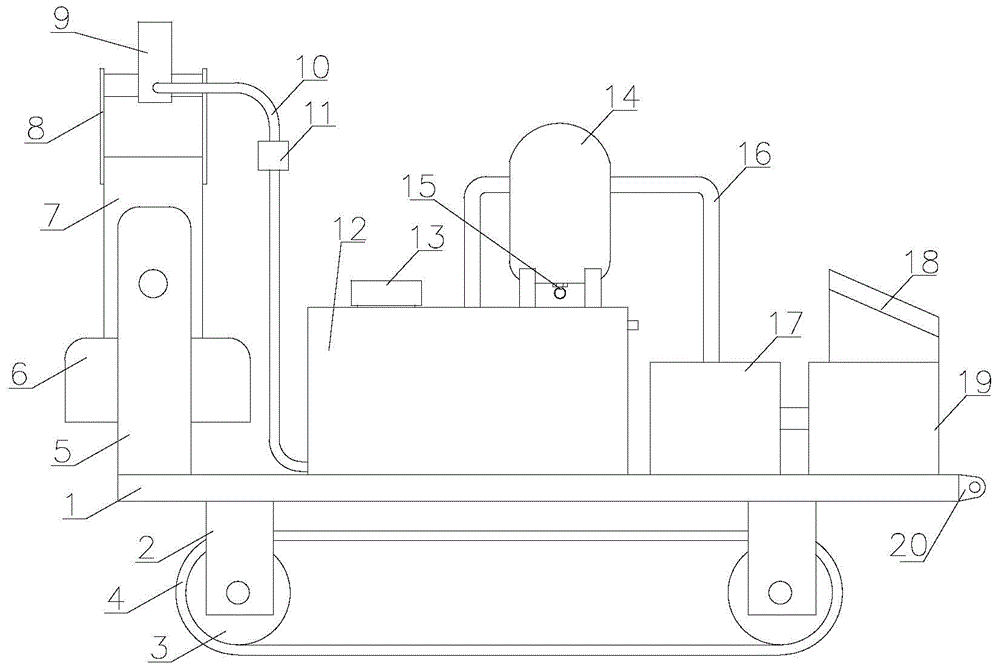

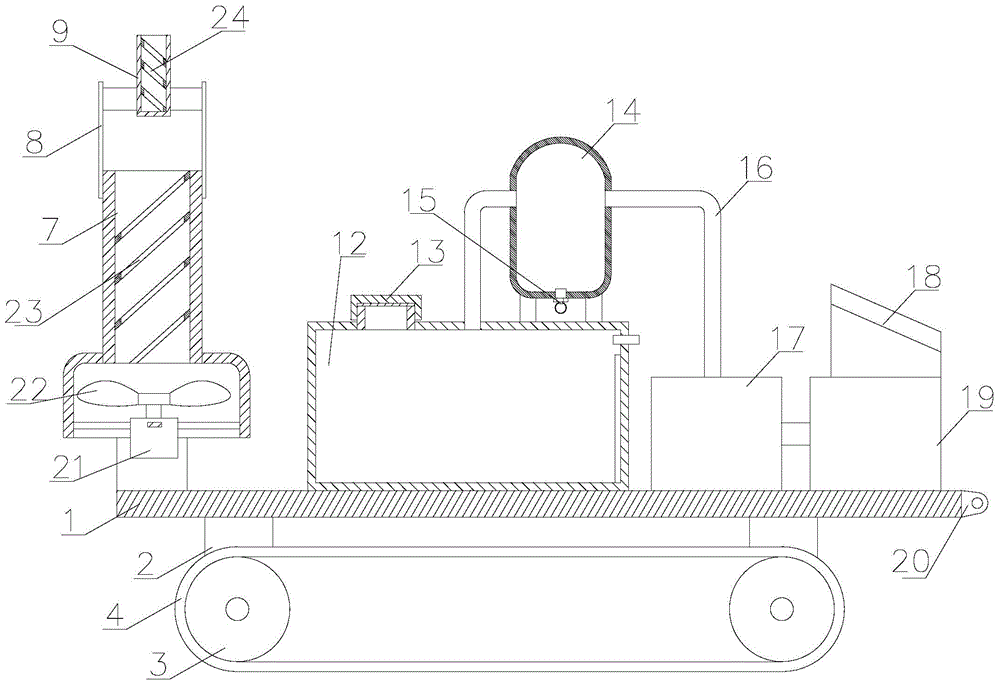

[0017] refer to figure 1 and figure 2 , a spiral-guided snowmaking machine of the present invention, comprising a seat plate 1, a wheel frame 2, a ground wheel 3, a snow belt 4, a snow spray device bracket 5, a fan housing 6, an air guiding tube 7, a water guiding tube bracket 8, Water guide cylinder 9, water pipe 10, solenoid valve 11, water tank 12, tank cover 13, gas storage bottle 14, drain valve 15, air guide pipe 16, air pump 17, electric control box 18, gasoline engine 19, traction ear 20, fan motor 21 , blade fan 22, air guide spiral plate 23 and water guide spiral plate 24, described seat plate 1 bottom is provided with wheel frame 2, and ground wheel 3 is installed on described wheel frame 2, and snow wheel 3 is installed on described ground wheel 3 Zone 4, the left side of the seat plate 1 is provided with a snow spraying device bracket 5, the snow spraying device bracket 5 is hingedly installed with an air guide tube 7, and the air guide tube 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com