Multi-station clamping device for fuel gas pipeline laser shock test

A gas pipeline and laser shock technology, applied in workpiece clamping devices, measuring devices, manufacturing tools, etc., to achieve the effects of reducing manpower, reducing production costs, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

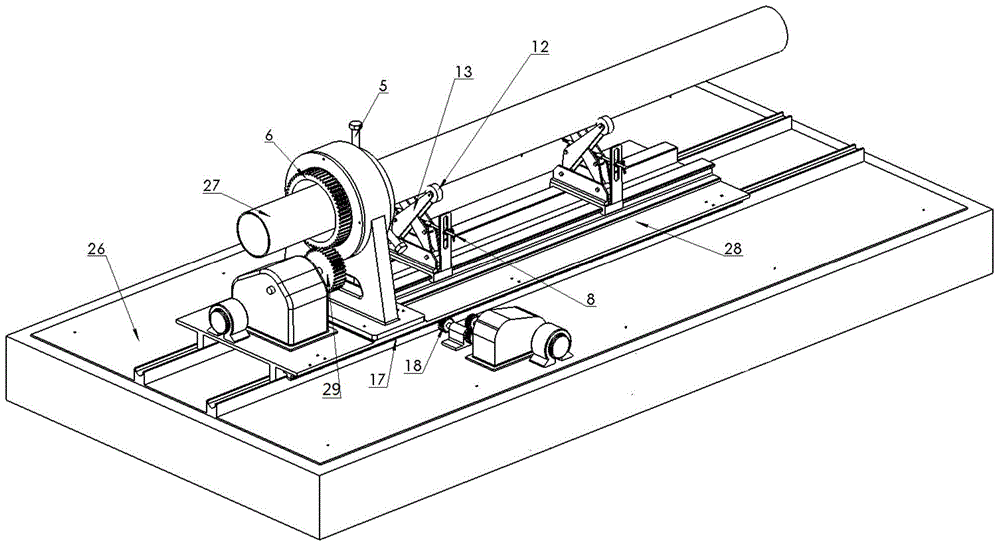

[0055] Such as figure 1 As shown, a multi-station clamping device for gas pipeline laser shock test, the movement structure mainly has three parts: gas pipeline clamping and rotary drive part; pipeline support length adjustable, variable diameter pipeline support part; pipeline axial Feed drive section.

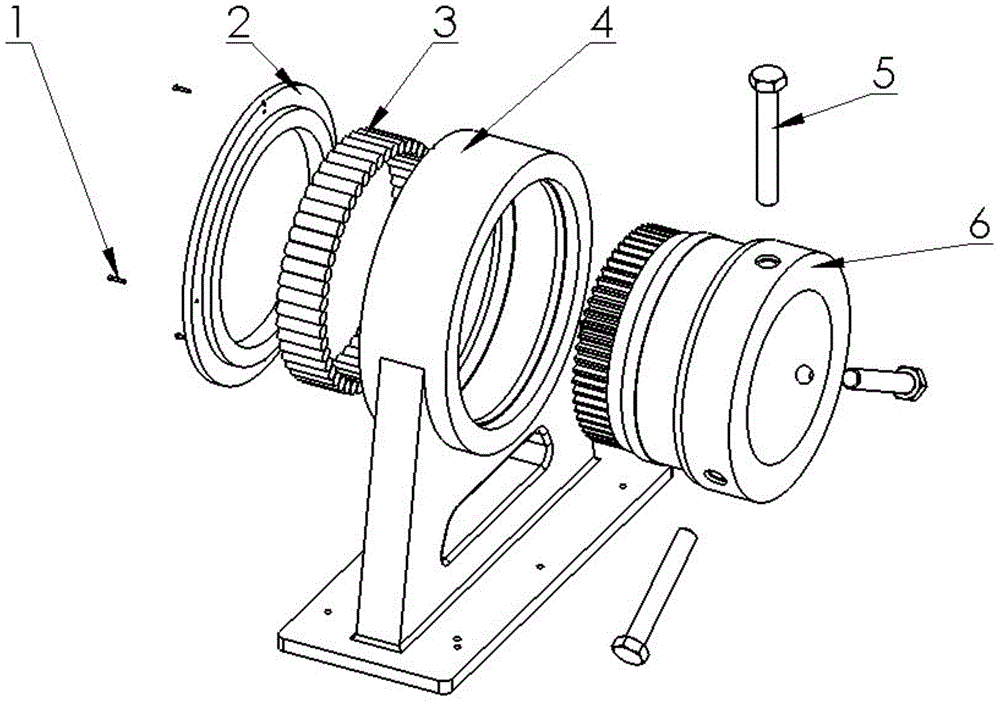

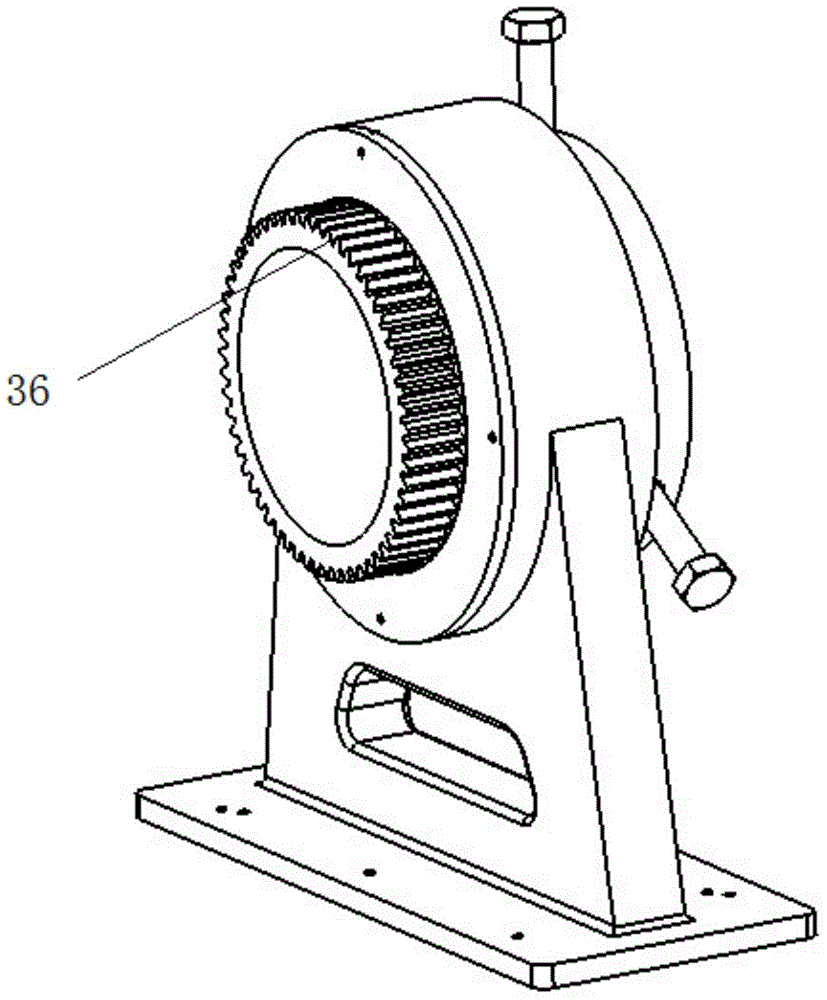

[0056] Such as figure 2 , image 3 As shown, the fixed bracket positions the clamping mechanism.

[0057] The main components of the mechanism: end cover 2, cylindrical roller 3, outer ring support 4, clamping bolt 5, inner ring 6 and screw 1. Among them, the selection of cylindrical roller 3 can ensure the stability of the gas pipeline rotation; the base of the outer ring bracket 4 is fixed on the movable base plate 28 to realize the feed movement along the pipeline axis; three clamping bolts 5 are distributed in the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com