Application of formic acid/zinc chloride solution for quantitative analysis of Lyocell A100 in mixed fiber and analysis method thereof

A zinc chloride solution and mixed fiber technology, applied in the field of quantitative analysis of lyocell A100, can solve the problems of inability to measure the content of lyocell fibers, unstable test data, inability to accurately distinguish, etc., and achieve stable and reliable test values. The effect of strong practicability and simple reagent preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Solvent Screening

[0041] The principle of the invention is to dissolve and remove other regenerated cellulose fibers from a mixture of known dry mass, collect residual Lyocell A100, and calculate its percentage in dry mass of the mixture after cleaning, drying and weighing. This gives the quality score for Lyocell A100.

[0042] Since regenerated cellulose fibers have similar physical and chemical properties, solvents that can dissolve regenerated cellulose fibers such as viscose fibers can also dissolve Lyocell A100. For example, the principle used in GB / T2910.6 is to use formic acid / zinc chloride The solution dissolves viscose fiber, cupro fiber or lyocell fiber, but does not dissolve cotton fiber. By detecting the mass of remaining cotton fiber, the mass fraction of cotton fiber or regenerated fiber blended with it is calculated.

[0043] The present invention has screened the viscose fiber dissolving, the solvent which does not dissolve the lyocell A1...

Embodiment 2

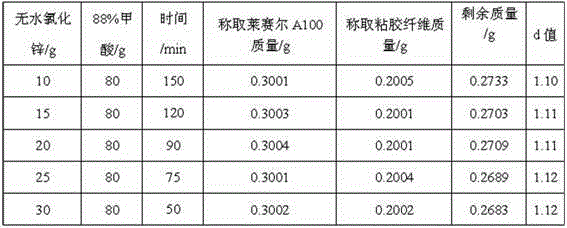

[0057] Example 2 Effects of Different Contents of Zinc Chloride on the Quantitative Detection of Lyocell A100

[0058] Weighed different zinc chlorides and added them to 80g of 88% formic acid to detect the impact on quantitative detection under different zinc chloride contents. The test results are shown in Table 2.

[0059] Table 2 The effect of zinc chloride content on the quantitative detection of Lyocell A100

[0060]

[0061] Note: d is the mass change correction factor for Lyocell A100.

[0062] From the above results, it can be seen that the preparation ratio of zinc chloride and 88% formic acid in the formic acid / zinc chloride solution is between 10:80-30:80, which has a certain influence on the test results. The presence of zinc chloride can promote the reaction to a certain extent. When the content of zinc chloride decreases, the reaction time will be extended accordingly; however, the content of zinc chloride has little effect on the d value. Considering t...

Embodiment 3

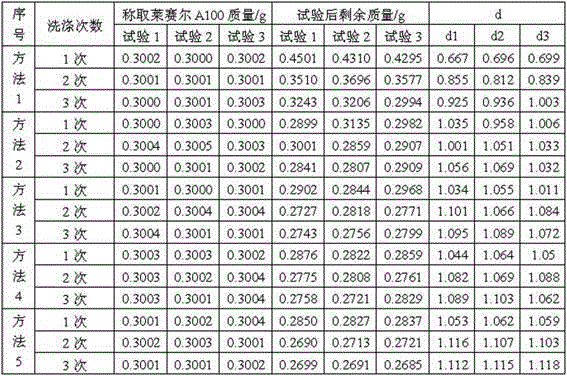

[0063] Example 3 Effects of Different Bath Ratio on Quantitative Detection of Lyocell A100

[0064] Under the conditions of dissolution temperature of 44°C, time of 90min, and oscillation frequency of 100 times / min, the bath ratio was changed, and Lyocell A100 was measured. The effect of liquor ratio on the experimental results is shown in Table 3.

[0065] Table 3 The effect of bath ratio change on the quantitative detection of Lyocell A100

[0066]

[0067] From the above results, it can be seen that the bath ratio is directly related to the d value of Lyocell A100. When the bath ratio is less than 1:100, the liquid formed after dissolution will be viscous due to the small volume of the solution, which is not conducive to filtration and cleaning. When the bath ratio reaches 1:1500, the d value tends to be stable. When the bath ratio is between 1:50 and 1:1500, the variation range of d value is between 1.09-1.19. Considering the general method of fiber quantitative an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com