Method for concentrating uranium from water solution with uranyl ions

A technology of uranyl ion and aqueous solution, which is applied in the field of enriching uranium, can solve the problems of unsuitability for industrial production, low reuse rate, and short service life, and achieve the effects of high reuse efficiency, low environmental pollution, and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

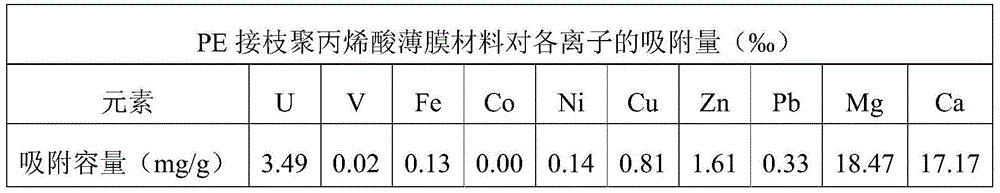

[0025] Adsorption of uranyl ions in concentrated seawater by PE grafted polyacrylic acid film material in embodiment 1

[0026] 1. Take 5L of concentrated seawater, in which the concentration of each ion (in terms of elements) is: UO 2 2+ 330ppb, VO 3 - 152ppb, Fe 3+ 141ppb,Co 2+ 5.3ppb, Ni 2+ 101ppb, Cu 2+ 65ppb, Zn 2+ 408ppb, Pb 2+ 34.6ppb, Mg 2+ 1.2×10 5 ppb, Ca 2+ 0.6×10 5 ppb.

[0027] 2. Add 0.1g of PE-grafted polyacrylic acid film material to it, and shake and absorb at room temperature (25°C) for 24 hours.

[0028] 3. Take out the PE grafted polyacrylic acid film material, and test the adsorption capacity of each ion on the PE grafted polyacrylic acid film material as shown in Table 1:

[0029] Table 1 PE grafted polyacrylic acid film material to the adsorption amount table of each ion

[0030]

Embodiment 2

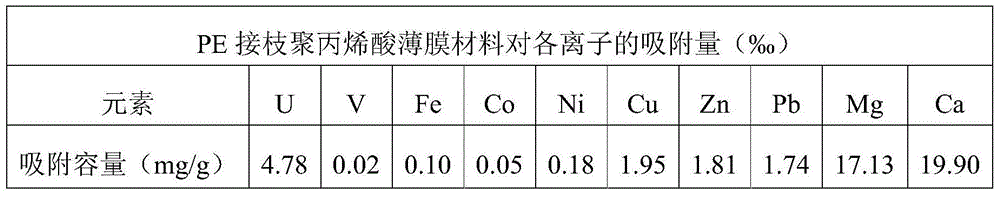

[0031] Adsorption of uranyl ions in seawater by PE grafted polyacrylic acid film material in embodiment 2

[0032] 1. Seawater passes through the PE grafted polyacrylic acid film material at a flow rate of 20ml / min, and is adsorbed at 25°C for 42 days (6 weeks). Among them, the concentration of each ion in seawater is shown in Table 2:

[0033] Table 2 Concentration of each ion in seawater

[0034] the element

U

V

Fe

co

Ni

Cu

Zn

Pb

Mg

Ca

Concentration (ppb)

3.5

1.9

40.6

0.3

1.1

5.4

8.2

31.6

1.2×10 5

0.6×10 5

[0035] 2. Take out the PE grafted polyacrylic acid film material, and test the adsorption capacity of each ion on the PE grafted polyacrylic acid film material, as shown in Table 3:

[0036] Table 3 PE grafted polyacrylic acid film material to the adsorption amount table of each ion

[0037]

Embodiment 3

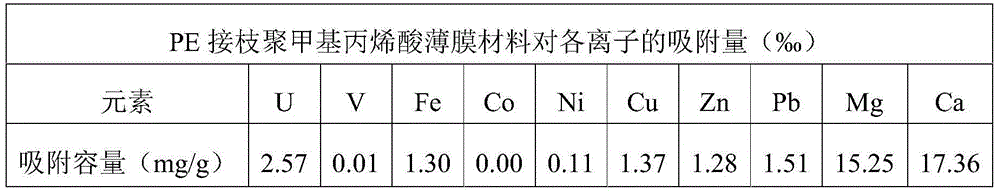

[0038] Adsorption of uranyl ions in seawater by PE grafted polymethacrylic acid film material in embodiment 3

[0039] 1. Place the PE grafted polymethacrylic acid film material in seawater at 25°C for 50 days, and the concentration of each ion in the seawater is the same as in Example 2.

[0040] 2. Take out the PE grafted polymethacrylic acid film material, wash away the sediment and microorganisms attached to the surface, and test the adsorption capacity of each ion on the PE grafted polymethacrylic acid film material as shown in Table 4:

[0041] Table 4 PE grafted polymethacrylic acid film material to the adsorption amount table of each ion

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com