Organic light-emitting diode and preparation method thereof

A light-emitting diode and organic technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems affecting performance and life, rising working temperature, and lowering of OLED light output efficiency, so as to improve yield rate, The effect of reducing the operating temperature rise of the device and widening the pattern reproduction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

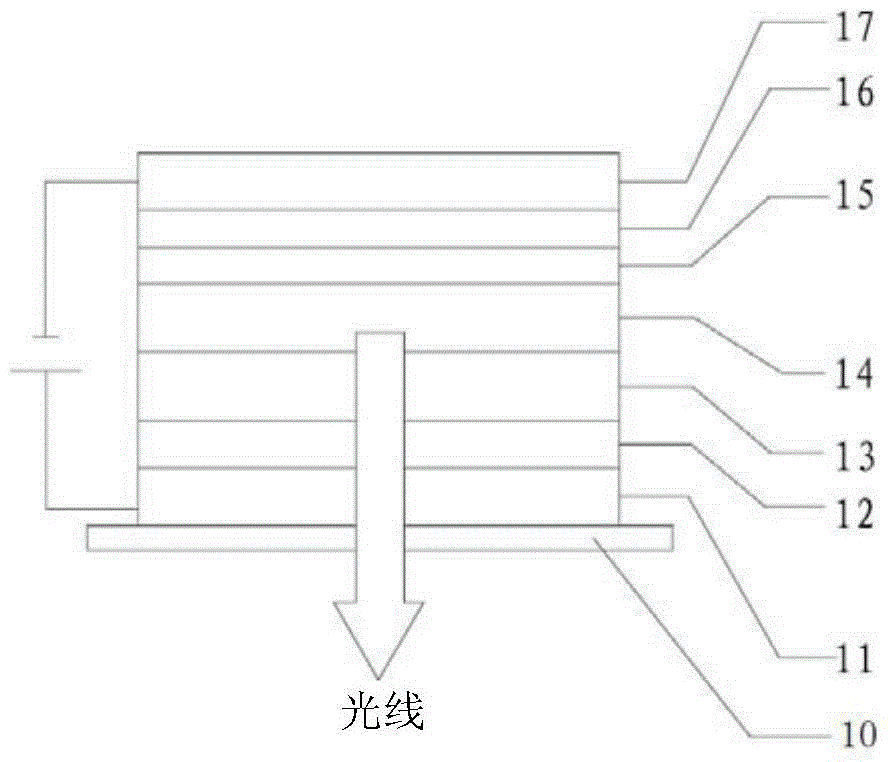

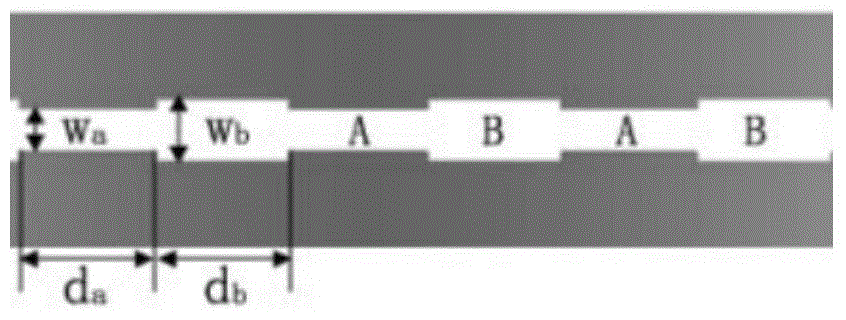

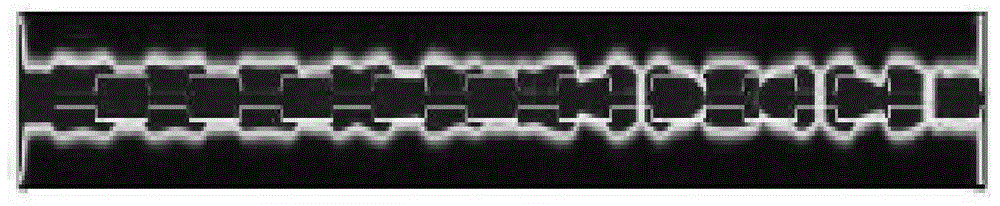

[0053] An organic light-emitting diode composed of a cathode, an organic electroluminescence unit and an anode, and a plasma nano-waveguide filter reflector is prepared on the cathode to increase the light extraction rate of the organic light-emitting diode.

Embodiment 2

[0055] An organic light-emitting diode composed of a cathode, an electron transport layer, a light-emitting layer, a hole transport layer and an anode in turn. The cathode is prepared with a MIM plasma waveguide filter reflector that can generate a band gap in the visible light wavelength range. Organic light-emitting diodes have a high visible light extraction rate.

Embodiment 3

[0057] An organic light-emitting diode consisting of a cathode, an electron injection layer, an electron transport layer, a light-emitting layer, a hole transport layer, a hole injection layer and an anode in turn, is prepared on the cathode to generate a number of wavelengths (the light emitted by the anode is relatively missing 1) The selective band gap MIM plasma waveguide filter reflector of the combination of frequency bands, the organic light emitting diode has a uniform visible spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com