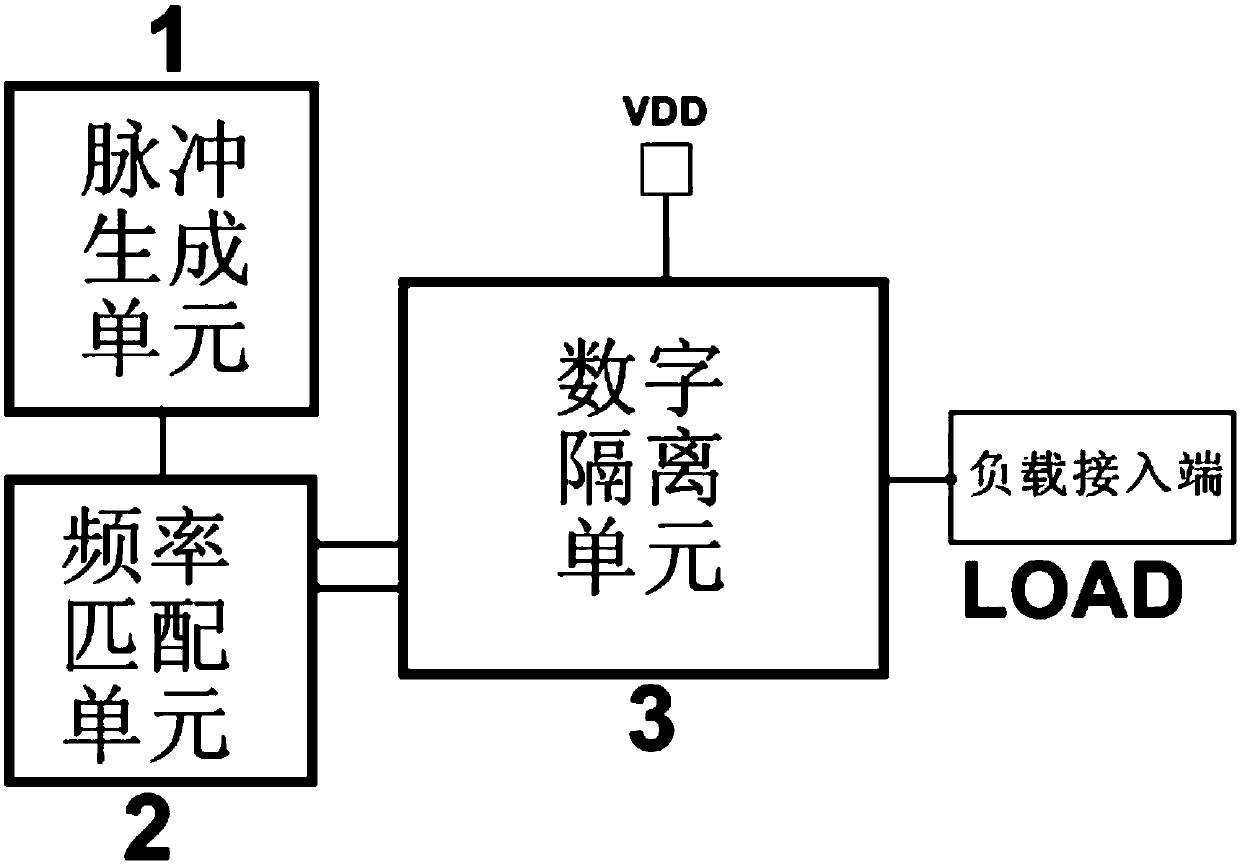

An isolated high frequency pulse generator

A high-frequency pulse generator technology, applied in the field of isolated high-frequency pulse generators, can solve problems such as noise disturbance, low frequency matching, lack of isolation protection for pulse generators, etc., and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

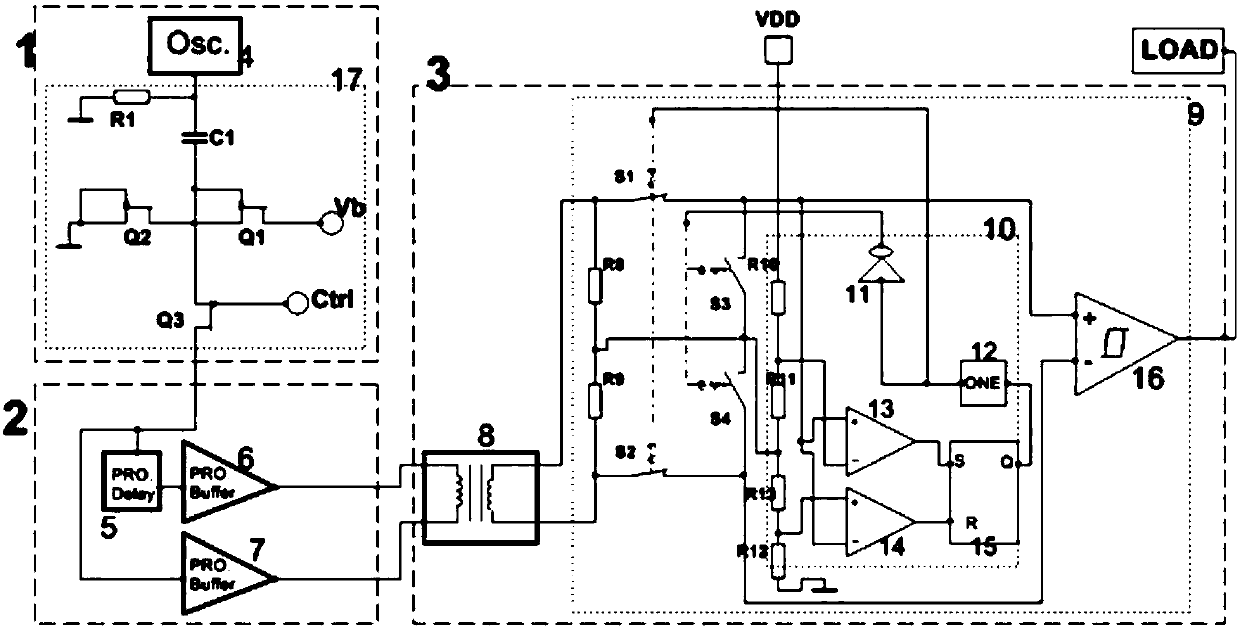

[0022] According to the operating frequency of the external load, a programmable delayer 5, a first programmable buffer 6 and a second programmable buffer 7 are set to complete frequency matching.

[0023] The digital isolation unit 3 includes a coil device 8 whose primary winding is connected to the output port of the frequency matching unit 2 , and a noise reduction unit 9 whose input port is connected to the secondary winding of the coil device 8 . The noise reduction unit 9 includes a first switch S1 connected in series with the secondary winding of the coil device 8, a second switch S2 and a Schmitt trigger 16, forming an effective output loop; including a parallel connection with the secondary winding of the coil device 8 The third switch S3 and the fourth switch S4 connected in series with the third switch S3 constitute a circuit for cutting off the noise of the secondary winding of the short-circuited coil device 8; it also includes an input feedback timing unit 10 for ...

Embodiment 2

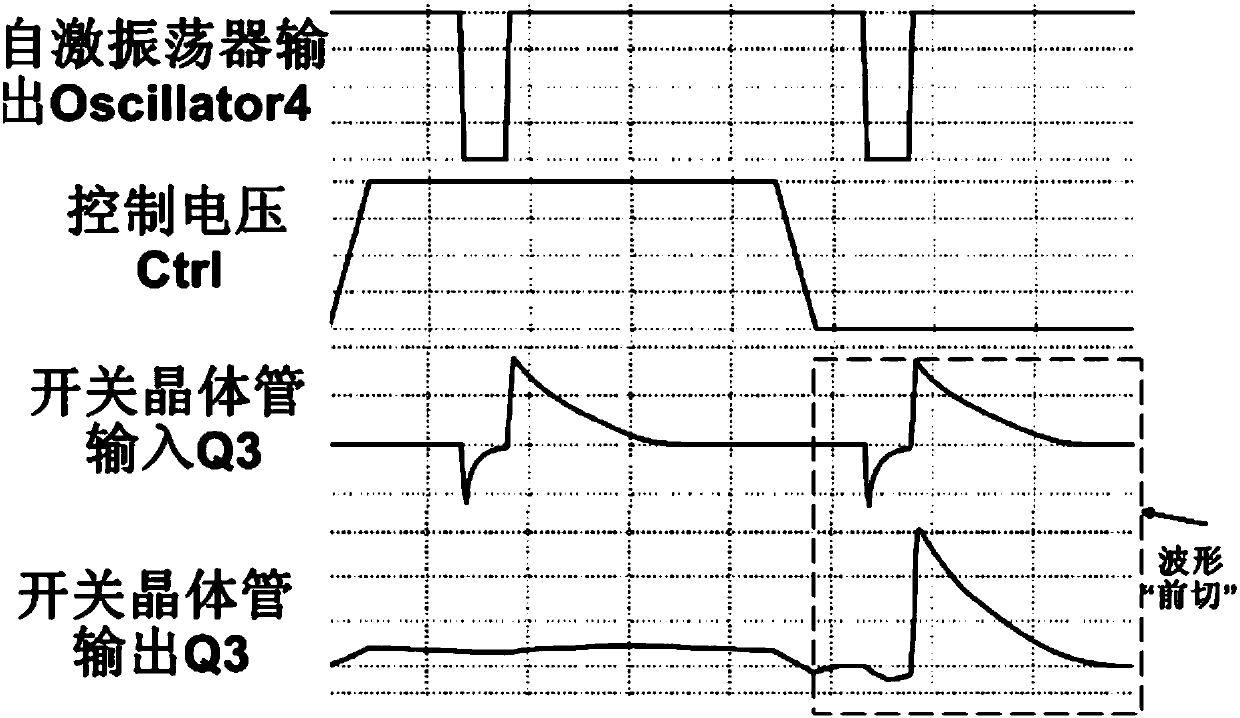

[0025] image 3 For the pulse generation waveform change diagram of the present invention, the self-excited oscillator 4 sends an oscillating square wave pulse, the control voltage Ctrl applies a high level, and the switching transistor Q3 has no output wave; the control voltage Ctrl cancels the high level, and the switching transistor Q3 "cuts forward" After the waveform is obtained an oscillating output.

Embodiment 3

[0027] Figure 4 It is a schematic diagram of the implementation of the transmission pulse of the present invention. After the pulse wave is output from the secondary winding of the coil device 8, the electromagnetic interference of the coil causes the noise oscillation opposite to the pulse wave electric parameter to occur at the end of the pulse waveform. At this time, the input feedback timing unit 10 is based on the high level of the pulse wave The pulse width obtains the input timing, which is fed back to the first switch S1 and the second switch S2, while the third switch S3 and the fourth switch S4 are turned off, so that the pulse wave is output. When the timing ends, the third switch S3 and the fourth switch S4 When it is turned on, the coil device 8 is short-circuited, so that the noise oscillation at the tail of the pulse waveform is cut off, and the "back-cut" of the pulse waveform is realized.

[0028] The invention has beneficial effects such as isolation protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com