3D food printer

A 3D printing and printer technology, applied in the field of 3D food printers, can solve the problems that 3D food printers cannot be well promoted and applied, model users cannot complete, and 3D software modeling, etc., to achieve simple and fast production, simple structure, Occupy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

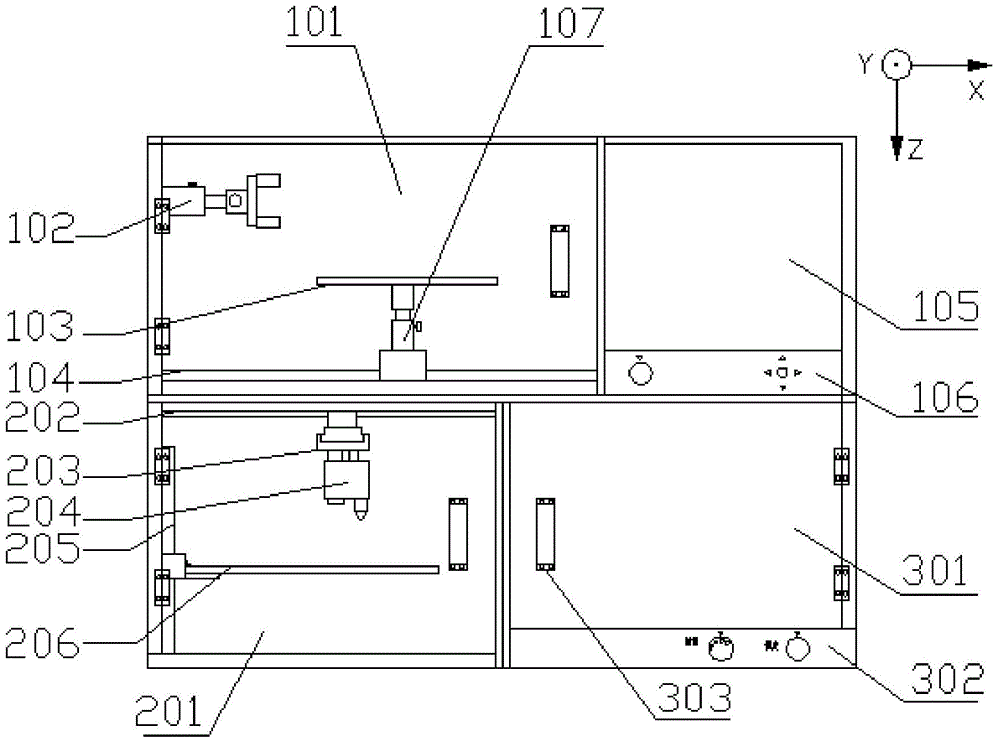

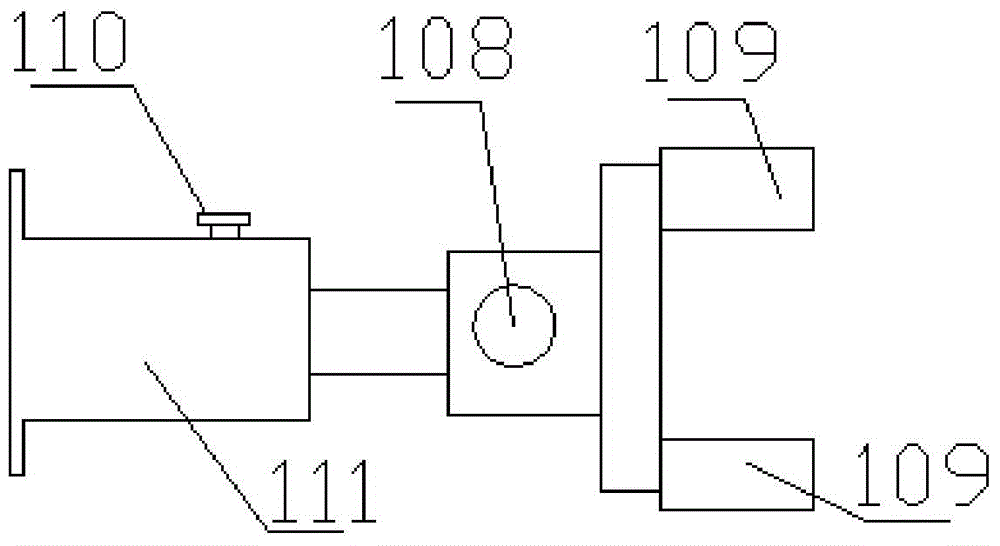

[0021] Such as figure 1 with figure 2 As shown, the 3D food printer of the present invention includes a cabinet, a 3D scanning device 101, a 3D printing device 201 and a baking device 301, wherein the 3D scanning device 101 is located on the first layer of the cabinet, and the 3D printing device 201 and the baking device 301 Located on the second floor of the box, the 3D scanning device 101, 3D printing device 201 and baking device 301 are all equipped with transparent doors, the 3D scanning device 101 and the 3D printing device 201 are connected by data transmission, and the baking device 301 Make the product printed by the 3D printing device 201 into food. The 3D food printer of the present invention uses the 3D scanning device 101 to model processed objects, especially some objects that are not easy to model, and automatically fits the 3D printing model by scanning the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com